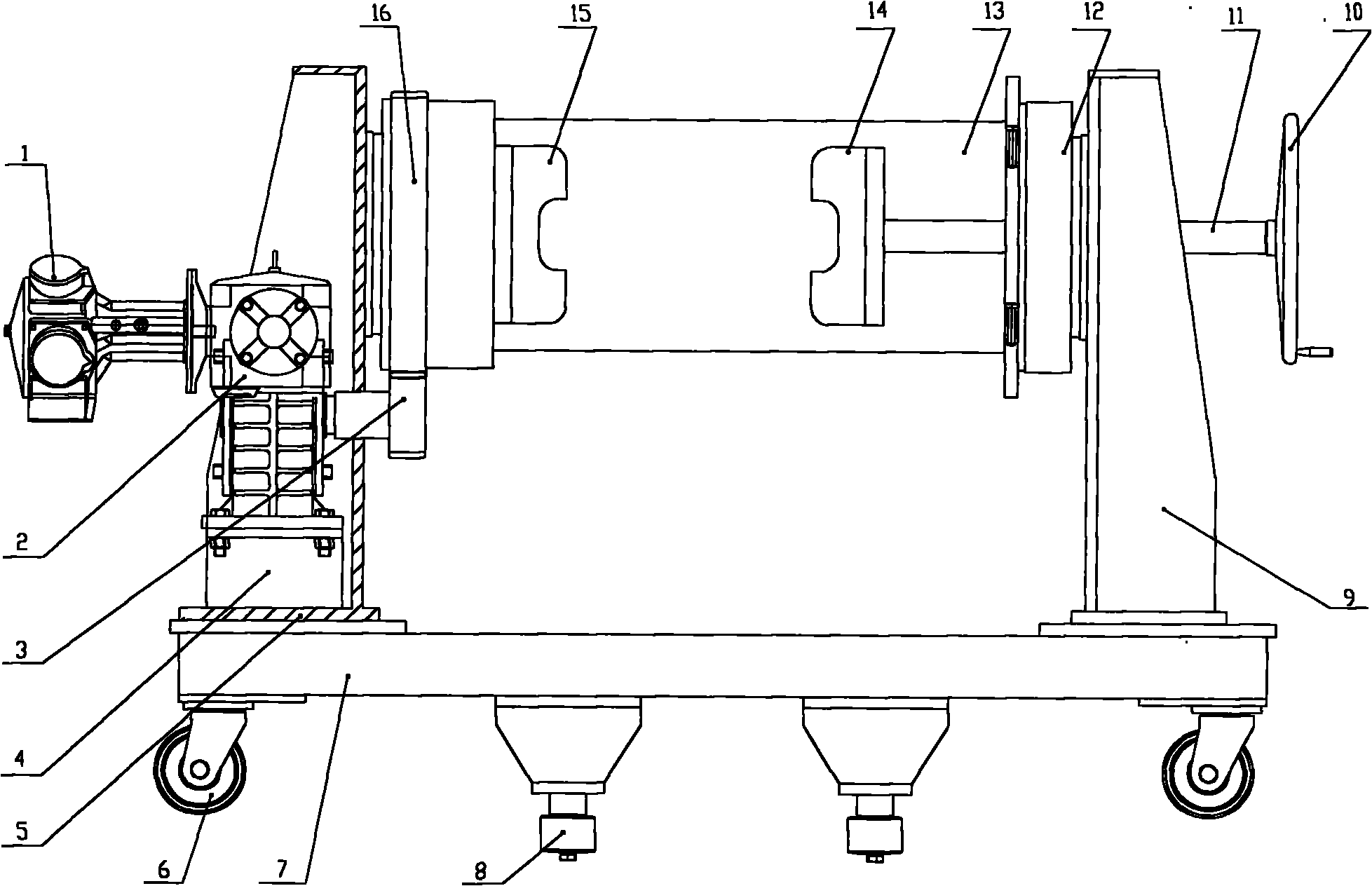

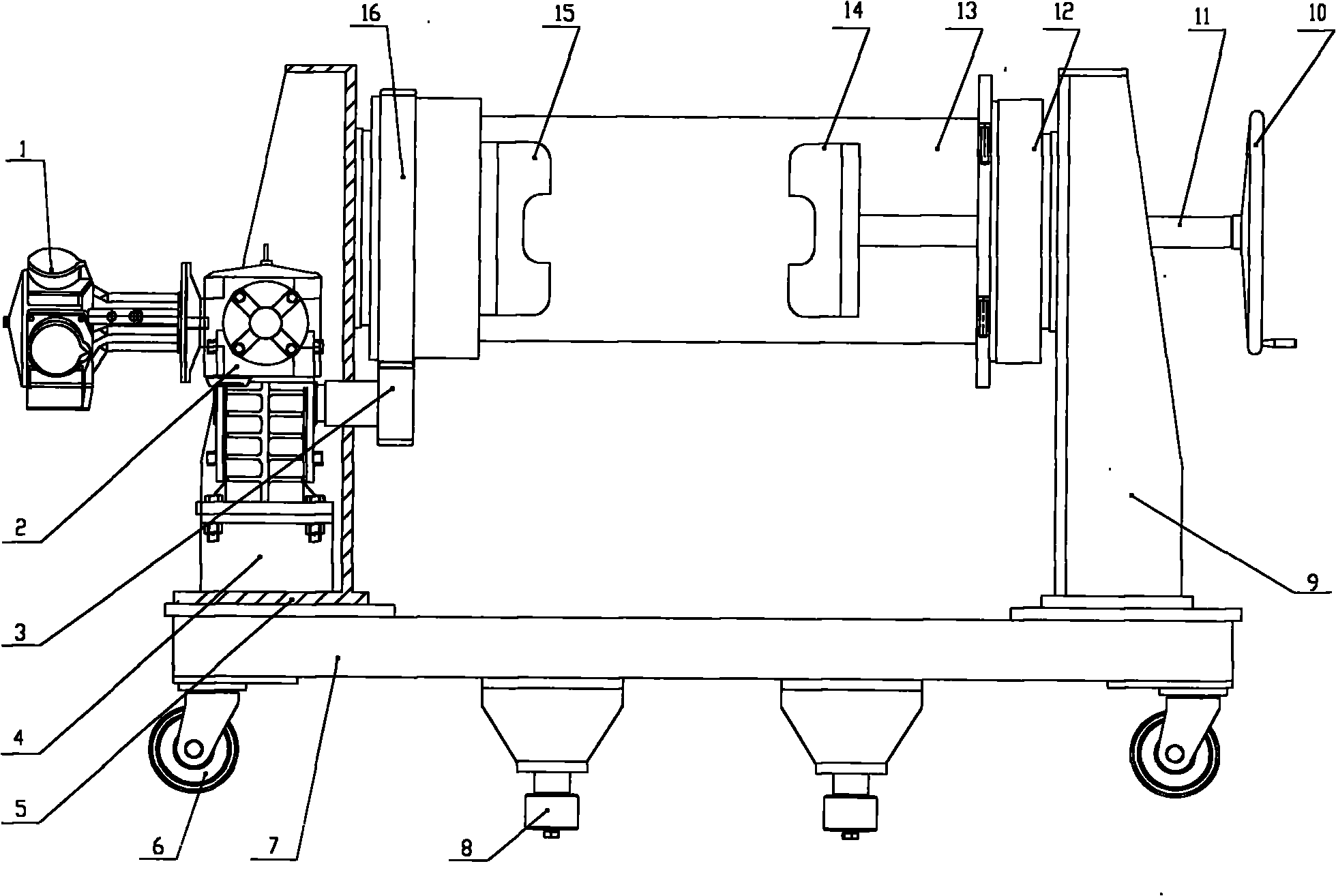

Overturning device for assembling hoist roller speed reducer assembly

A technology for assembly and flipping devices, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity for workers, difficulty in ensuring assembly quality, and small reel height, so as to ensure production safety, The effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0010] As shown in the accompanying drawings, the turning device used in the assembly of the crane drum reducer assembly of the present invention is mainly composed of power and transmission device, support assembly, clamping device and chassis car. Among them: the chassis car is mainly composed of a frame 7, four wheels 6 and two guide wheels 8; wherein the frame 7 is an integral structural member welded by steel plates, and the four wheels 6 are symmetrically installed on the frame 7 through the wheel frame. On both sides of the bottom of the bottom, the wheels 6 can rotate on the erected plane; two guide wheels 8 are installed on the longitudinal axis position of the bottom of the vehicle frame 7 by their wheel frames, and the guide wheels can rotate on the horizontal plane. The support assembly is mainly composed of a left support 5 and a right support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com