Ultraviolet sterilizer

An ultraviolet and sterilizer technology, applied in the field of multi-working conditions ultraviolet sterilizers, can solve the problems of uneven arrangement of ultraviolet disinfection lamps, incomplete sterilization, and inability to disassemble, so as to avoid uneven distribution of ultraviolet rays and incomplete reaction. , the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

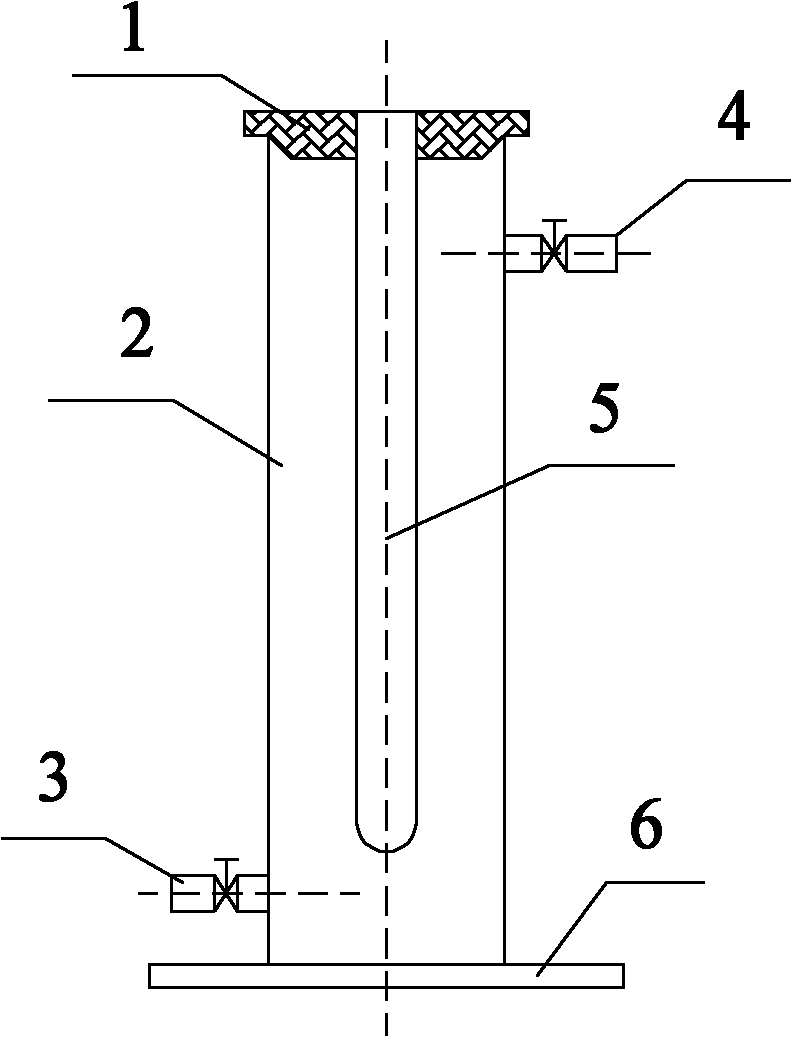

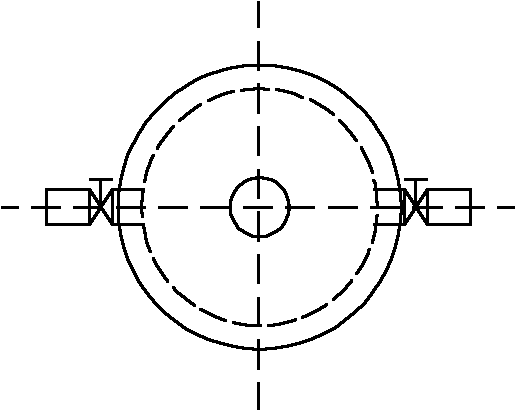

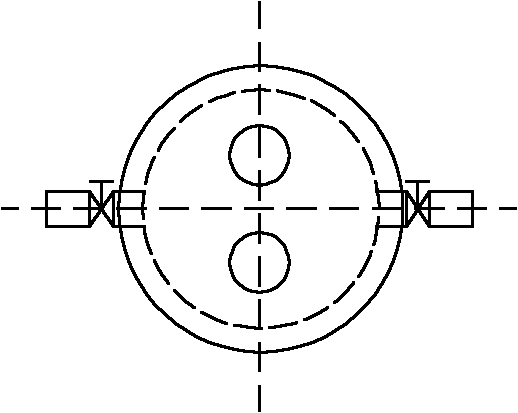

[0030] Such as figure 1 As shown, the ultraviolet sterilizer of the present invention is composed of a quartz sleeve panel 1 , a reaction chamber 2 , a water inlet 3 , a water outlet 4 , a quartz sleeve 5 , and a base 6 . In this embodiment, the disinfection reaction chamber 2 is an upright cylindrical chamber, the chamber 2 is made of stainless steel, and the inner wall is polished to improve the reflection ability of ultraviolet rays and enhance the radiation intensity. The bottom of the cavity 2 is closed by welding with the base 6. The lower end of the cavity 2 is provided with a water inlet 3, and the opposite upper end is provided with a water outlet 5. It also has a quartz sleeve panel 1, and the quartz sleeve panel 1 is embedded with quartz The sleeve is used for filling the ultraviolet lamp tube during the reaction, and the distance b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com