A waste gas treatment system used in electroplating process and its working method

A technology for waste gas treatment and electroplating process, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

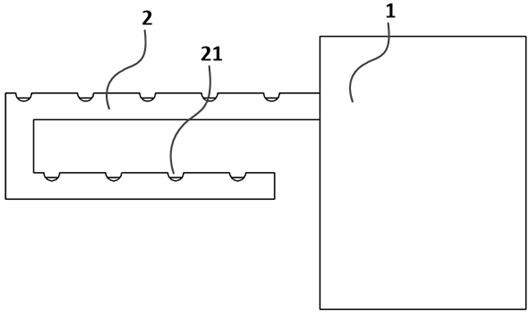

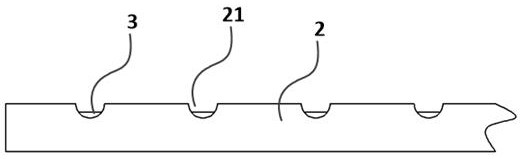

[0047] refer to Figure 1-4 as an example.

[0048] A waste gas treatment system used in an electroplating process, comprising: a treatment chamber (1) and a processor.

[0049] The exhaust gas treatment system also includes an air extraction module and a reaction module. The processing chamber is provided with a gas guide port, and the gas guide port passes through the processing chamber.

[0050] The air extraction module includes a circulating pump and an air extraction pipeline 2 . The air extraction pipeline 2 is arranged outside the processing chamber, the air extraction pipeline 2 is connected to the circulation pump, and the circulation pump is connected to the processor. The processor outputs an on signal or an off signal to the circulation pump, and the circulation pump is turned on or off according to an instruction of the processor. The circulation pump draws the electroplating waste gas through the suction pipe 2 .

[0051]The circulation pump is connected to...

Embodiment 2

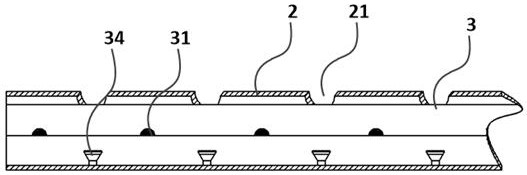

[0067] refer to Figure 5-6 as an example.

[0068] This embodiment is basically the same as the above-mentioned embodiment, the difference is that, as a preferred mode of this embodiment, the processing chamber 1 includes a processing module, and the processing module includes a reaction pool 5 and a ventilation pipe 4. The air extraction inner pipeline 3 is in communication with the ventilation pipe 4, and the ventilation pipe 4 is in communication with the reaction pool 5. Reaction chemicals are stored in the reaction pool 5, and the reaction chemicals are used to react with the electroplating waste gas.

[0069] The electroplating waste gas in the exhaust inner pipeline 3 is output to the ventilation pipe 4, and the ventilation pipe 4 introduces the electroplating waste gas into the reaction tank 5. The electroplating exhaust gas reacts with the solution in the reaction tank 5 .

[0070] As a preferred manner of this embodiment, the reaction pool 5 includes at least two...

Embodiment 3

[0087] This embodiment is basically the same as the above-mentioned embodiment, the difference is that, as a preferred mode of this embodiment, a recovery module is arranged in the air extraction pipeline 2, and the recovery module includes a sealing layer, a recovery port, and a drainage tube . The sealing layer is arranged on the bottom of the air extraction pipeline 2, the sealing layer is used to seal the bottom of the air extraction pipeline 2, the recovery port is arranged on the sealing layer, and the recovery port is used to collect the The liquid in the suction pipeline 2 is described. The drainage tube is arranged in the sealing layer, and the drainage tube guides the liquid in the sealing layer to the waste liquid collection place.

[0088] The sealing layer is used to separate the liquid from the electroplating waste gas, the recovery port is used for the infiltration of the liquid, and the drainage tube is embedded in the suction pipe 2 to drain the liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com