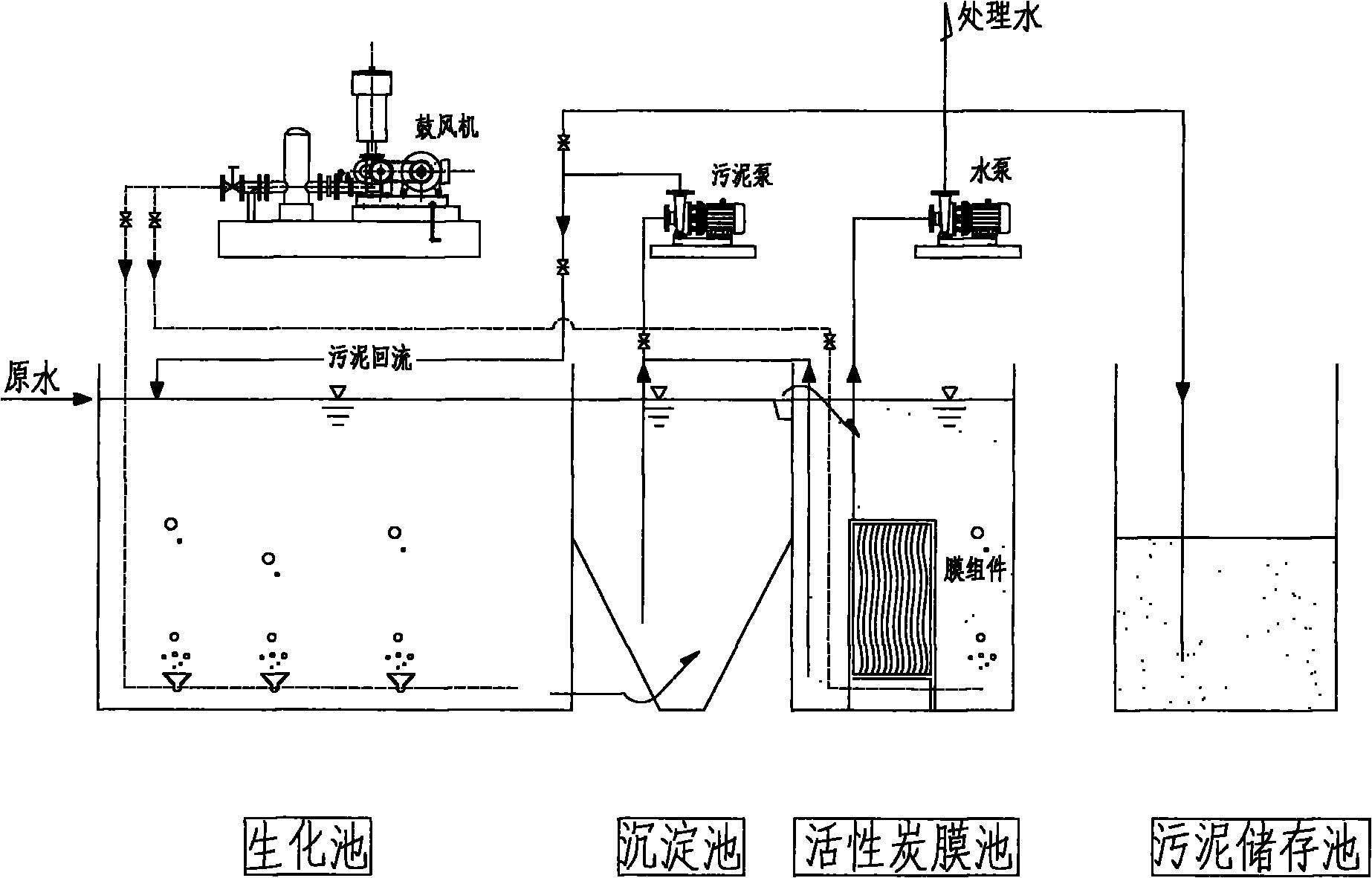

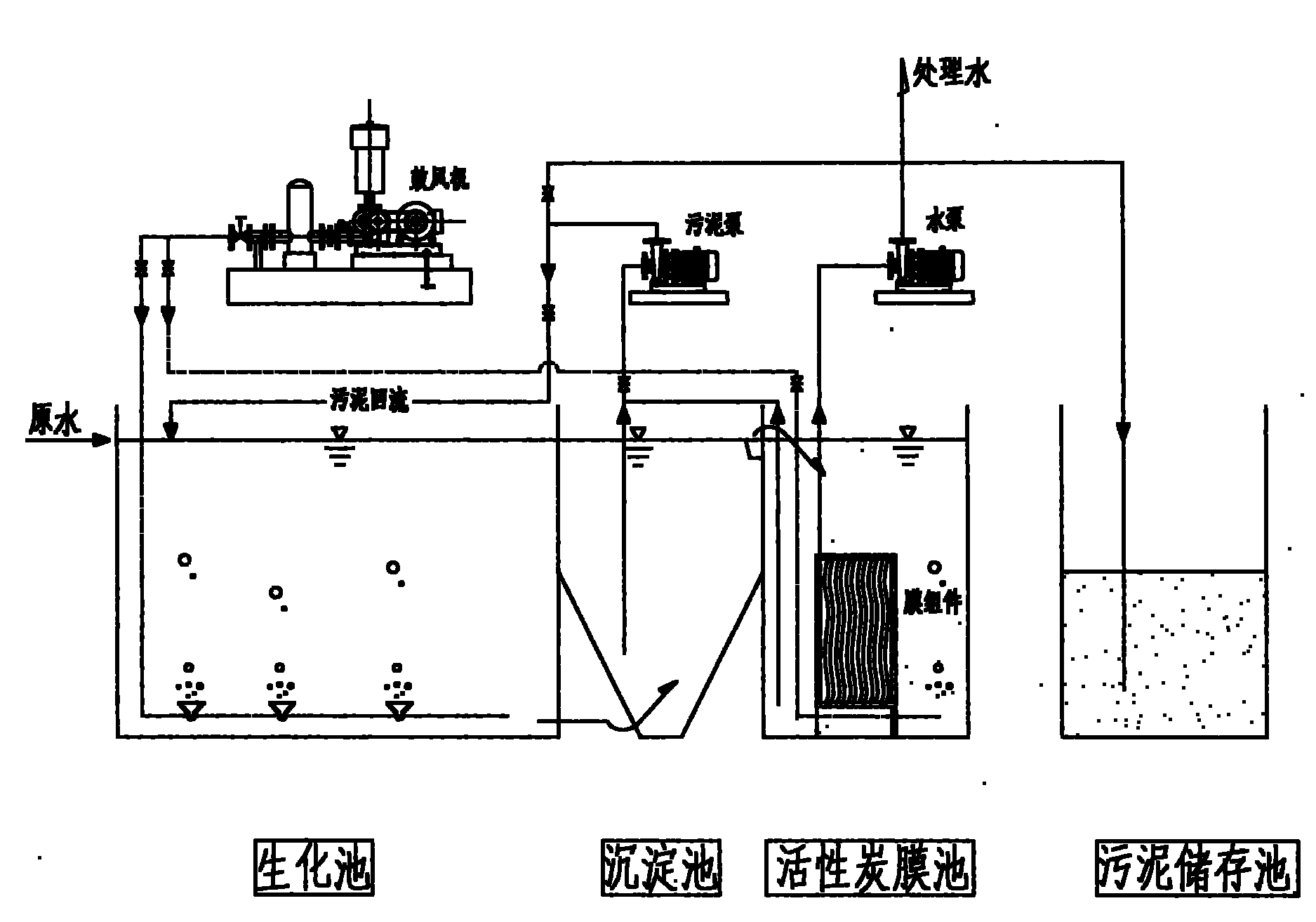

Membrane active carbon bioreactor (MACBR) with sedimentation basin

A technology of activated carbon and sedimentation tank, which is applied in the field of membrane activated carbon bioreactor MACBR with sedimentation tank, which can solve the problems of increased energy consumption and reduced membrane service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005] The traditional membrane bioreactor is subdivided into biochemical reaction tanks, sedimentation tanks, activated carbon membrane tanks and sludge storage tanks. The biochemical reaction tank still maintains a high sludge concentration to maintain a high level of treatment efficiency. After the sewage passes through the biochemical reaction tank, it enters the sedimentation tank for sedimentation. The sludge mainly composed of microorganisms is deposited in the lower part of the sedimentation tank, and the supernatant enters the activated carbon membrane tank. The supernatant of the sedimentation tank is treated water that has been purified to a certain extent under the action of microorganisms. The concentration of pollutants contained in the water has been greatly reduced, but some dissolved organic matter that is difficult to be degraded by microorganisms still exists in the supernatant. . Membrane modules are installed in the activated carbon membrane tank and an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com