Method for preventing box culvert head drop during box culvert jacking construction and used steel ship bow slope

A box culvert technology during construction, applied in the construction, road bottom and other directions, can solve the problems affecting the safety and quality of the project, damage or damage, insufficient strength, etc., to ensure the quality of the project construction, prevent the problem of tying, and be easy to manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and non-limiting embodiment:

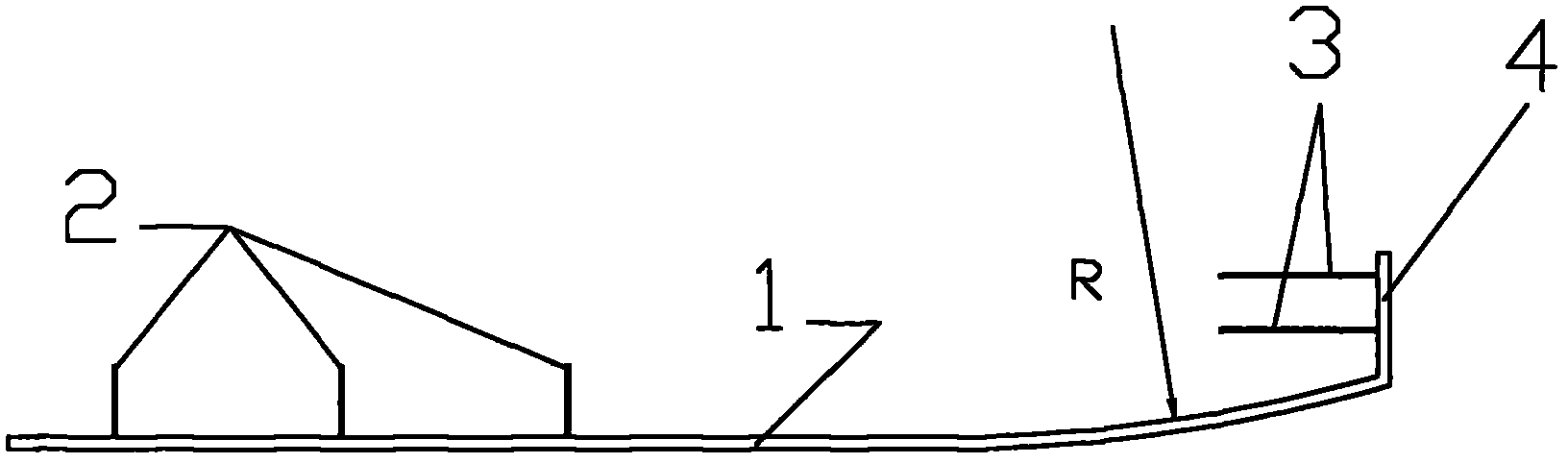

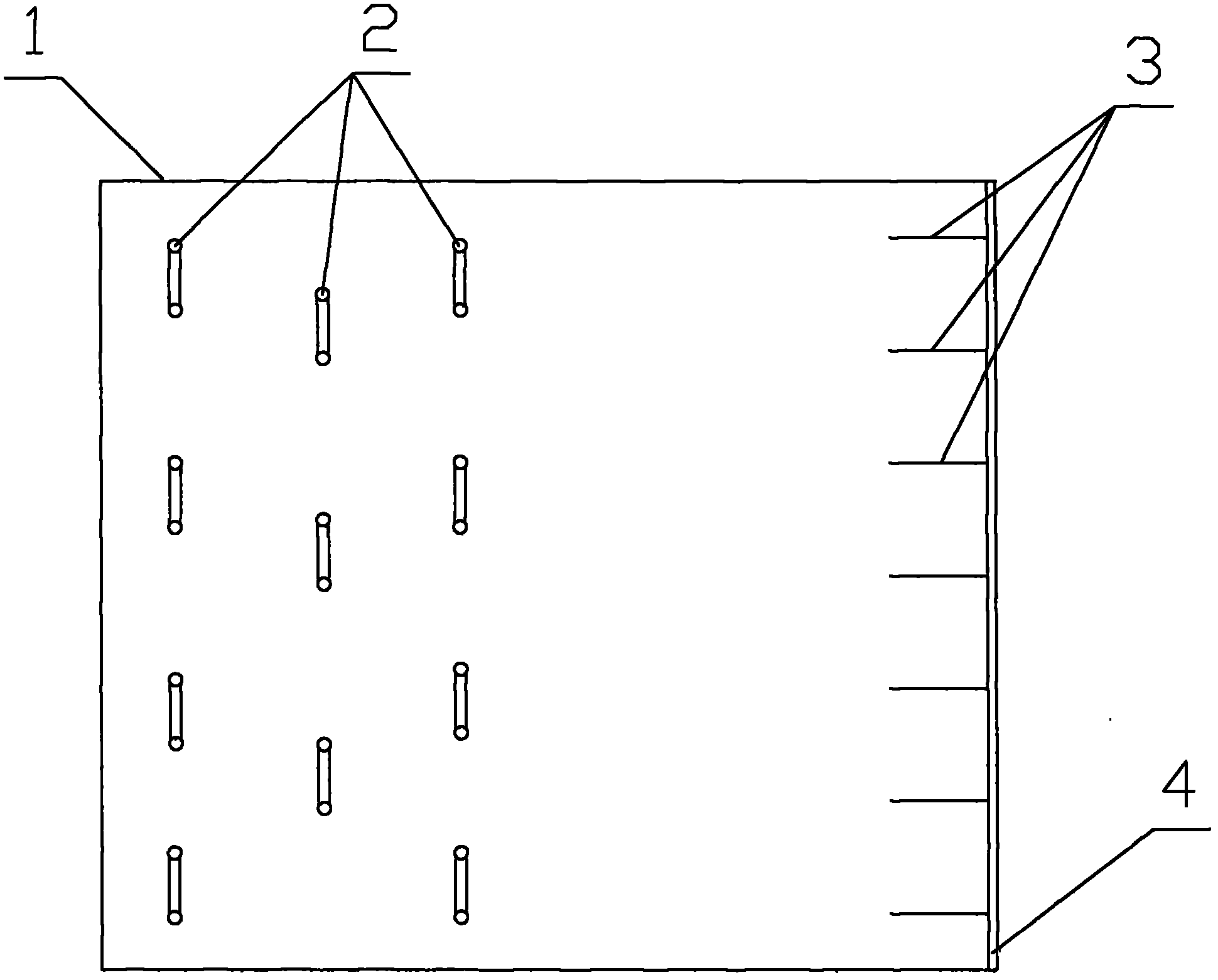

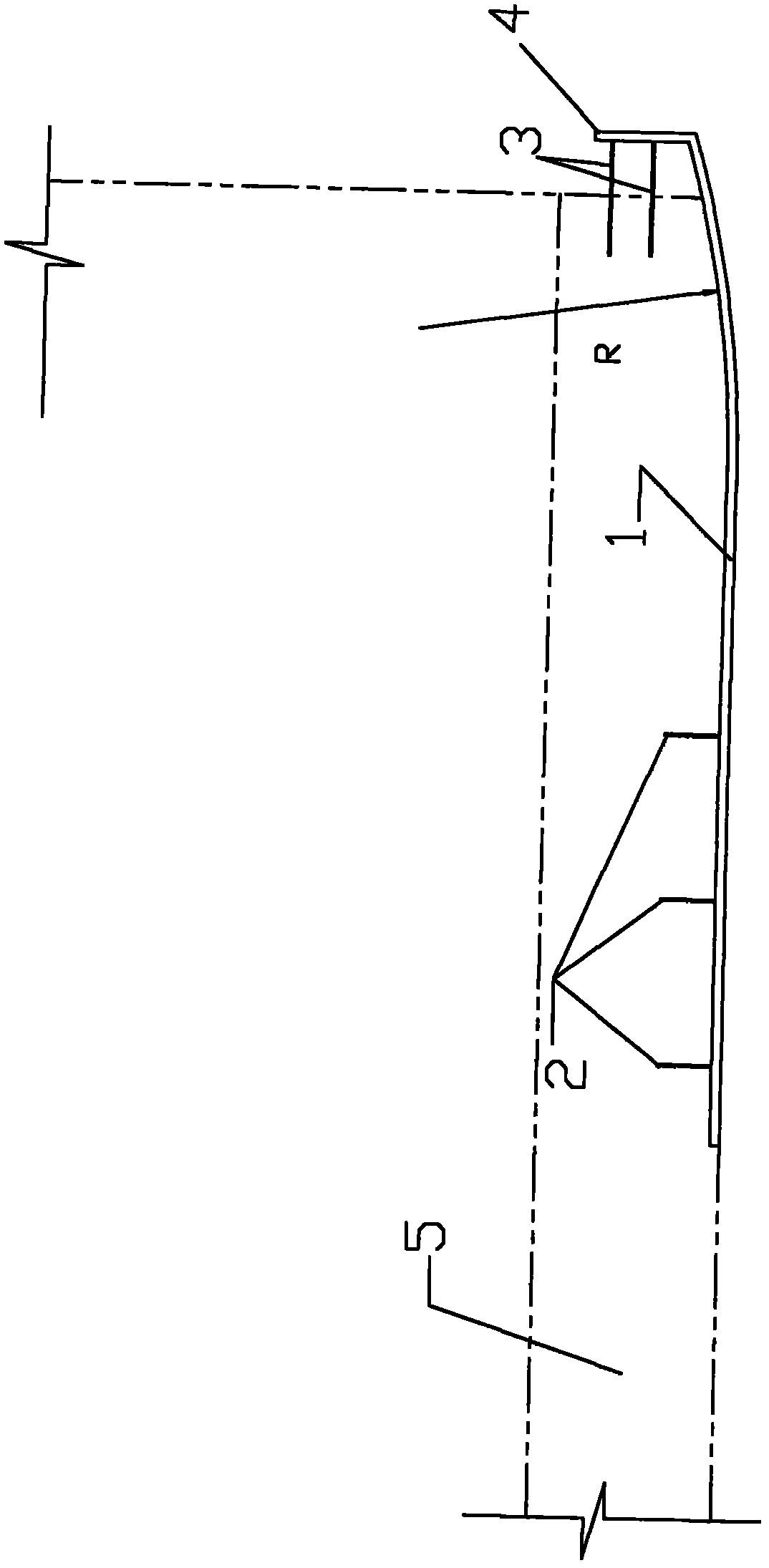

[0020] as attached Figure 1-3 As shown, the steel bow slope for box culvert jacking shown in this embodiment includes a bottom steel plate 1 and a front steel plate 4, and the bottom steel plate 1 is processed by a steel plate with a certain thickness, which has a straight section and an upward bending The arc section, wherein, the radian of the arc section can be properly adjusted according to actual needs, the bottom steel plate 1 is fixed with at least one bottom anchor bar 2 for fixing the bottom of the box culvert bottom plate 5, and the bottom anchor bar 2 can be a steel bar, Its quantity is determined according to design requirements, and the bottom anchor rib 2 and the bottom steel plate 1 can be fixed by welding. The front steel plate 4 is arranged on the front end of the arc section of the bottom steel plate 1, and it is processed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com