Automatic recording instrument for dynamic compaction construction

A recorder and automatic technology, which is applied in the direction of instruments, registration/indication, time register, etc., can solve the problems of construction quality control risks, high cost, and more manpower, so as to ensure the quality of project construction and save human resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings.

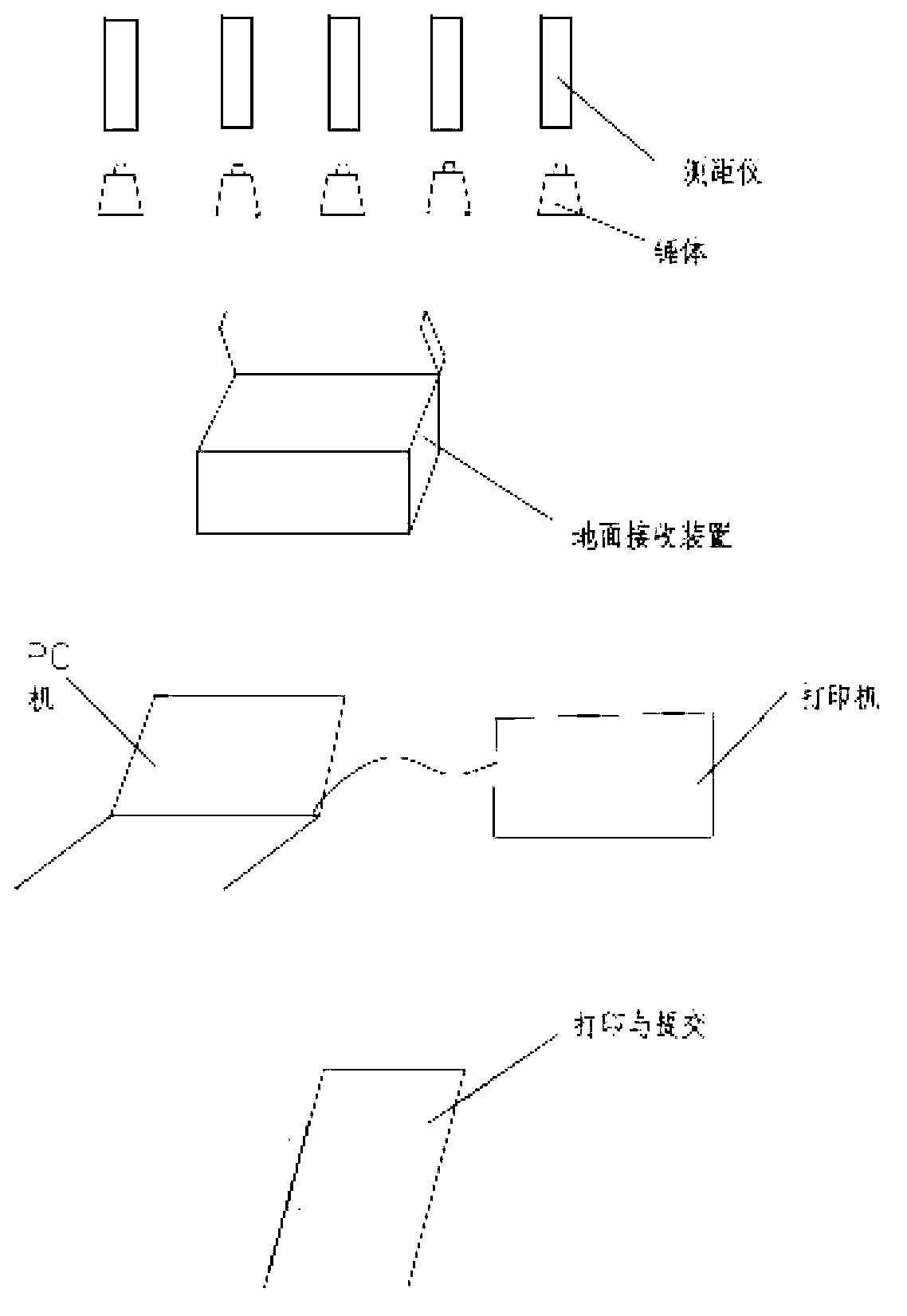

[0037] Automatic recorder for dynamic compaction construction, including rangefinder, ground receiving device, and PC.

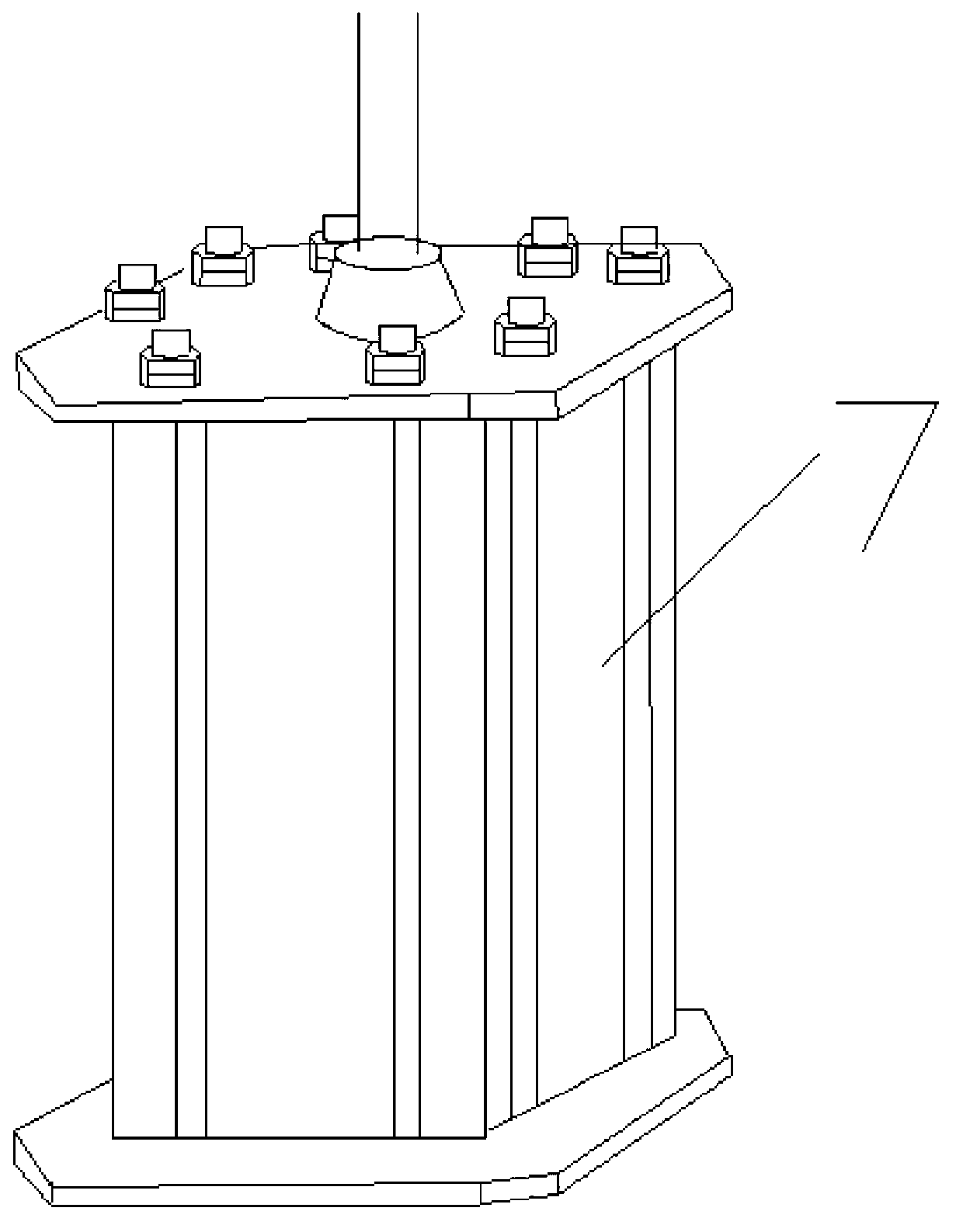

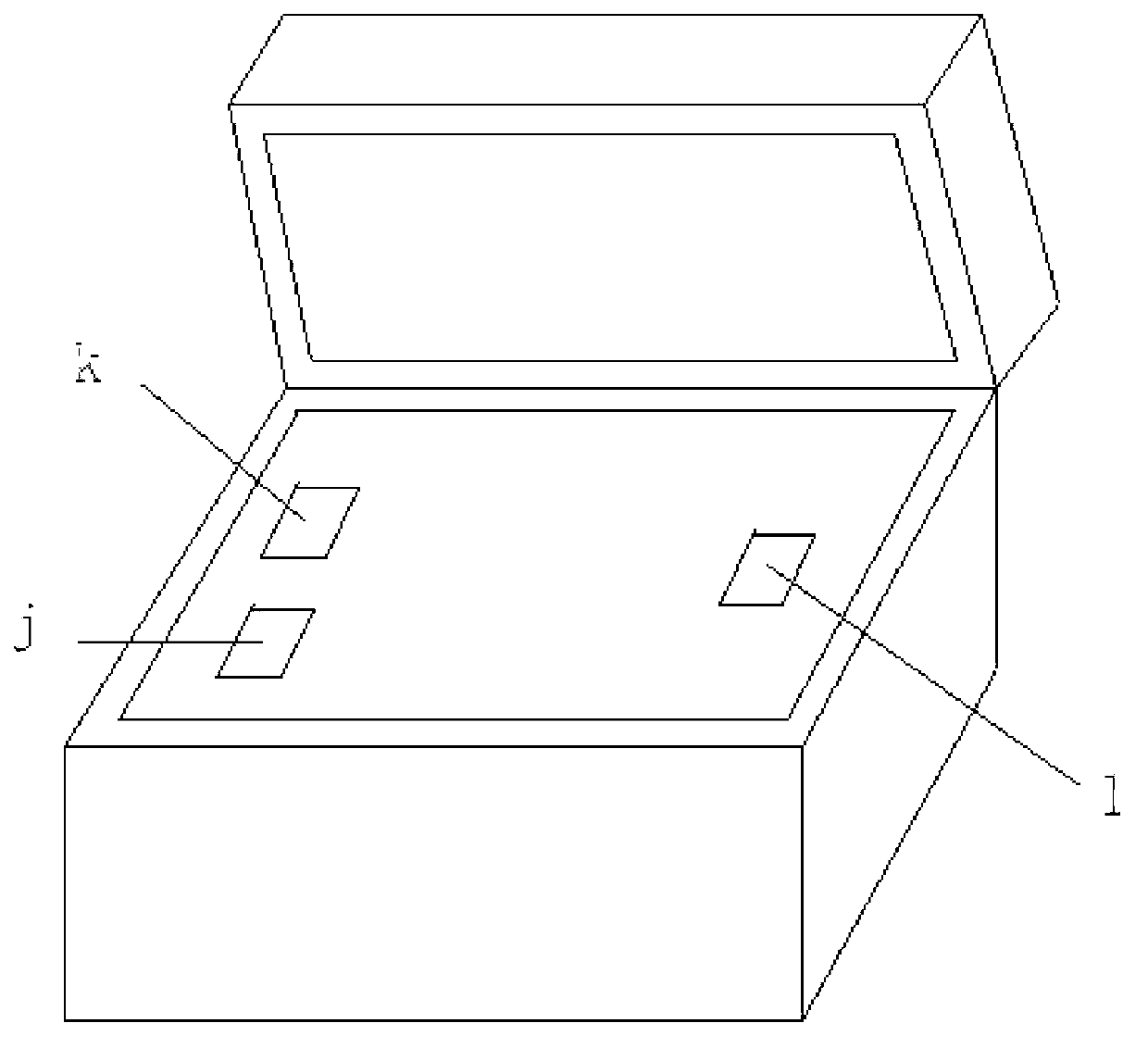

[0038]In the figure, a rangefinder is installed on the top of the dynamic compactor to measure the falling distance. The distance measuring instrument has a laser beam generator JG and a distance measuring system. The distance measuring system automatically tracks and monitors the lifting process of the tamper. The distance measuring system includes a laser beam generator module a (its function is to control the emission of the laser, and its principle is to The generator issues instructions to make the laser generator emit laser), the laser beam emission frequency control module b (its function is to control the frequency of laser emission), the laser beam reflection signal optical lens module c (its function is to focus the received reflected las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com