Walling machine

A technology of wall-laying machine and frame, which is applied in construction, building structure, and processing of building materials, etc. It can solve problems such as inconvenient use, complex structure, poor stability and firmness of the wall-building machine frame, and achieve Good practicality, stability and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

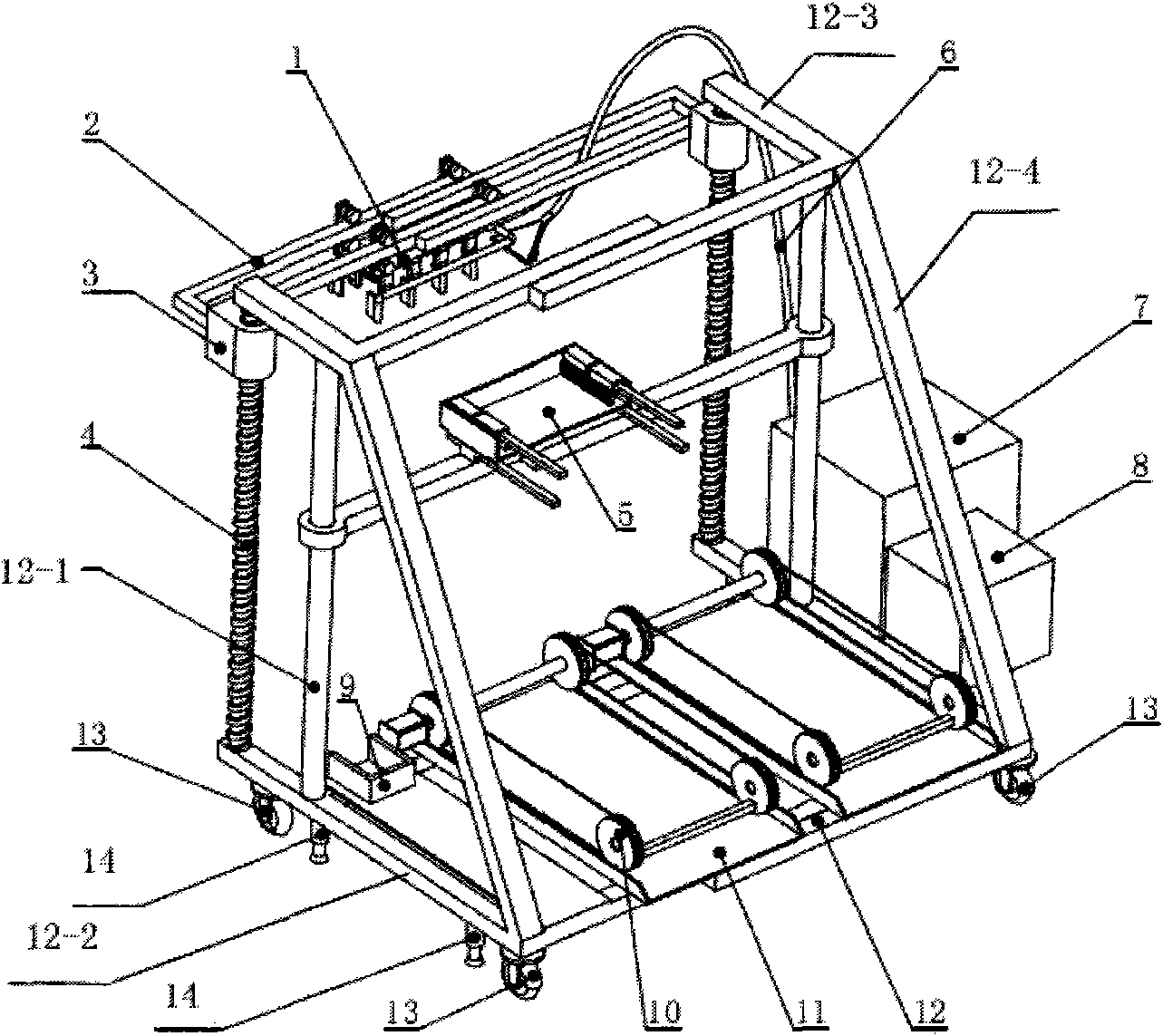

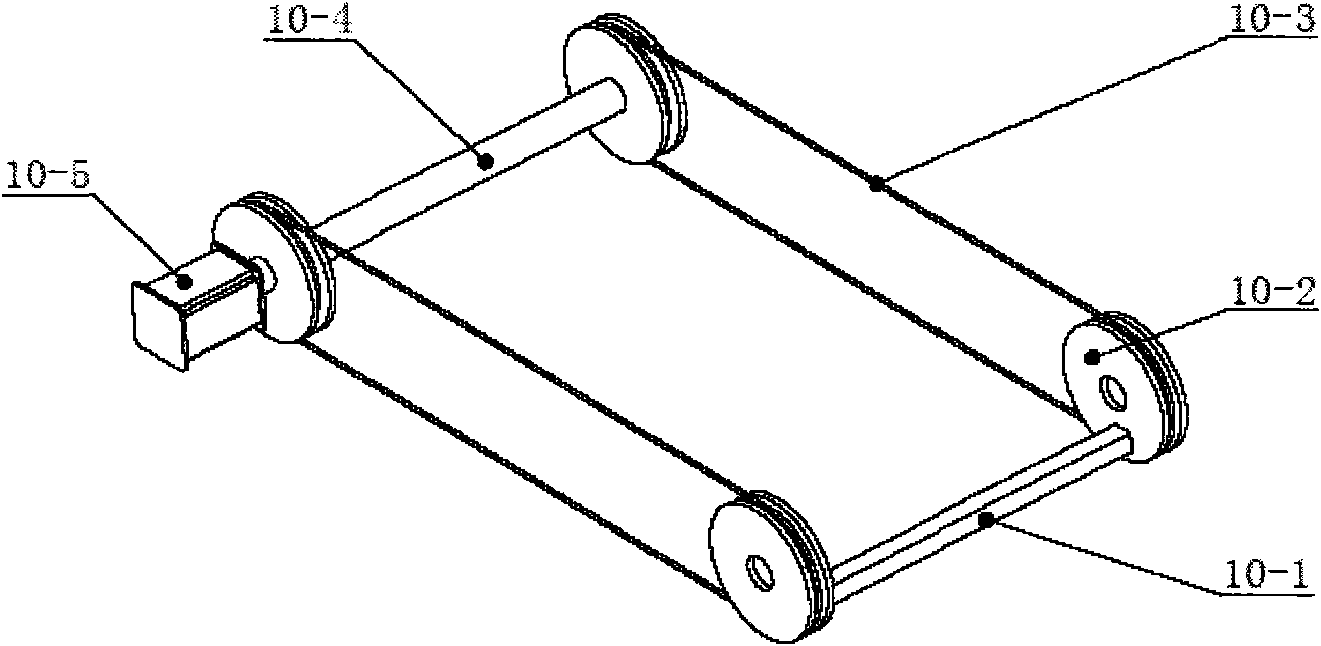

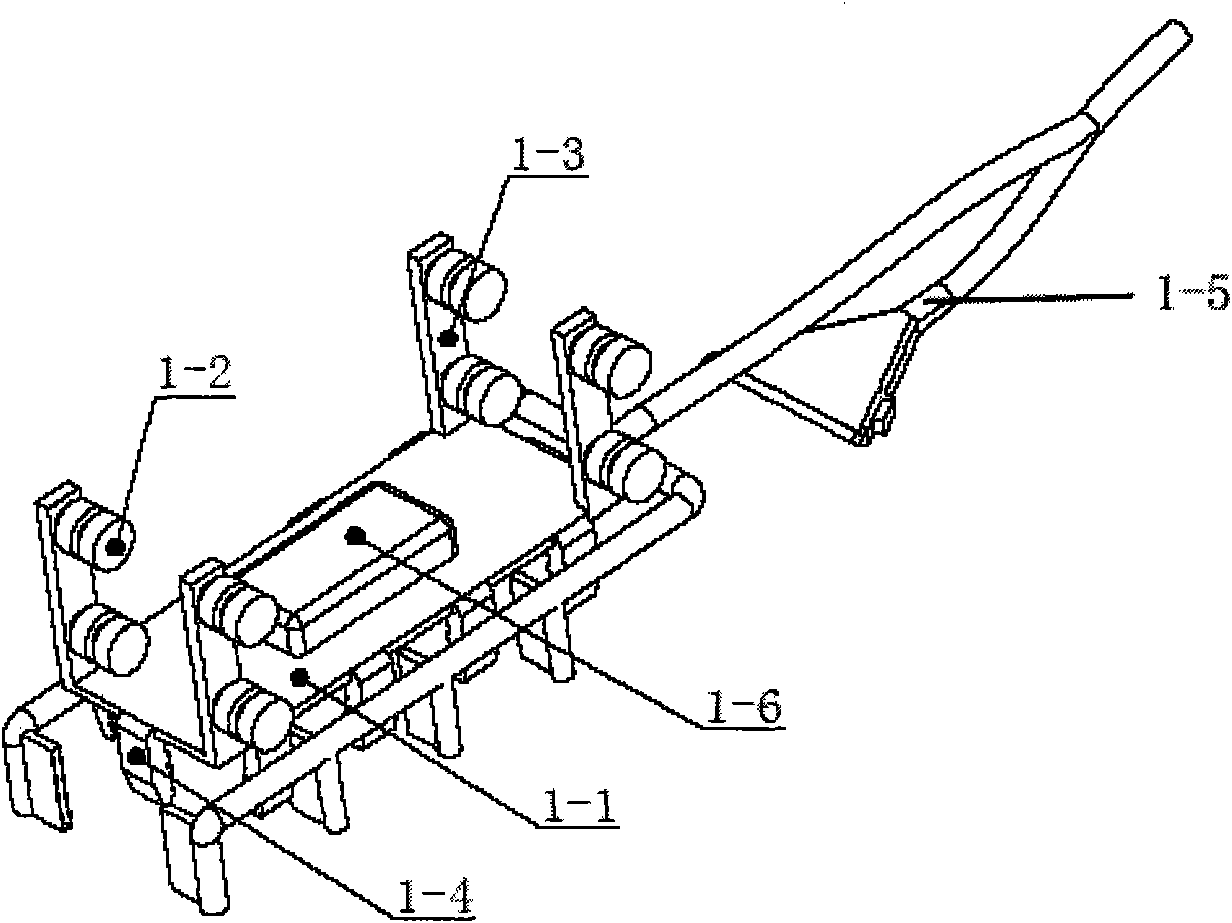

[0014] Such as figure 1 The shown wall-laying machine includes a brick building device 1, a brick transport mechanism 5, a mortar transport mechanism, a brick stack moving device 10, a frame 12 and a control system 8, and the frame 12 includes a bottom beam 12-2, Upper beam 12-3, lifting column 4 and frame column 12-1. The bottom crossbeam 12-2 of frame 12 is provided with Anping regulating foot 14; Diagonal braces 12-4 are arranged between the ends of the bottom beam 12-2. The frame 12 is a rectangular parallelepiped frame. Since the beams of the frame 12 are formed by lapping or plugging two shorter beams, the length of the frame 12 can be adjusted with the length of the wall. Adjust pin 14 and universal caster 13, can automatically settle down and move freely. A lifting beam 2 is arranged between the lifting columns 4, and the brick masonry device 1 is suspended on the lifting beam 2 through the double-track sheave 1-2; the brick transport mechanism 5 is arranged between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com