Universal speed reducer of sliding gear meshing pair

A technology of meshing pair and reducer, which is applied in the direction of gear transmission, belt/chain/gear, transmission, etc., can solve the problems of low transmission efficiency, movement interference, and inability to output power of the reducer with small tooth difference, so as to avoid additional The effect of motion existence, low processing cost, and avoidance of power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

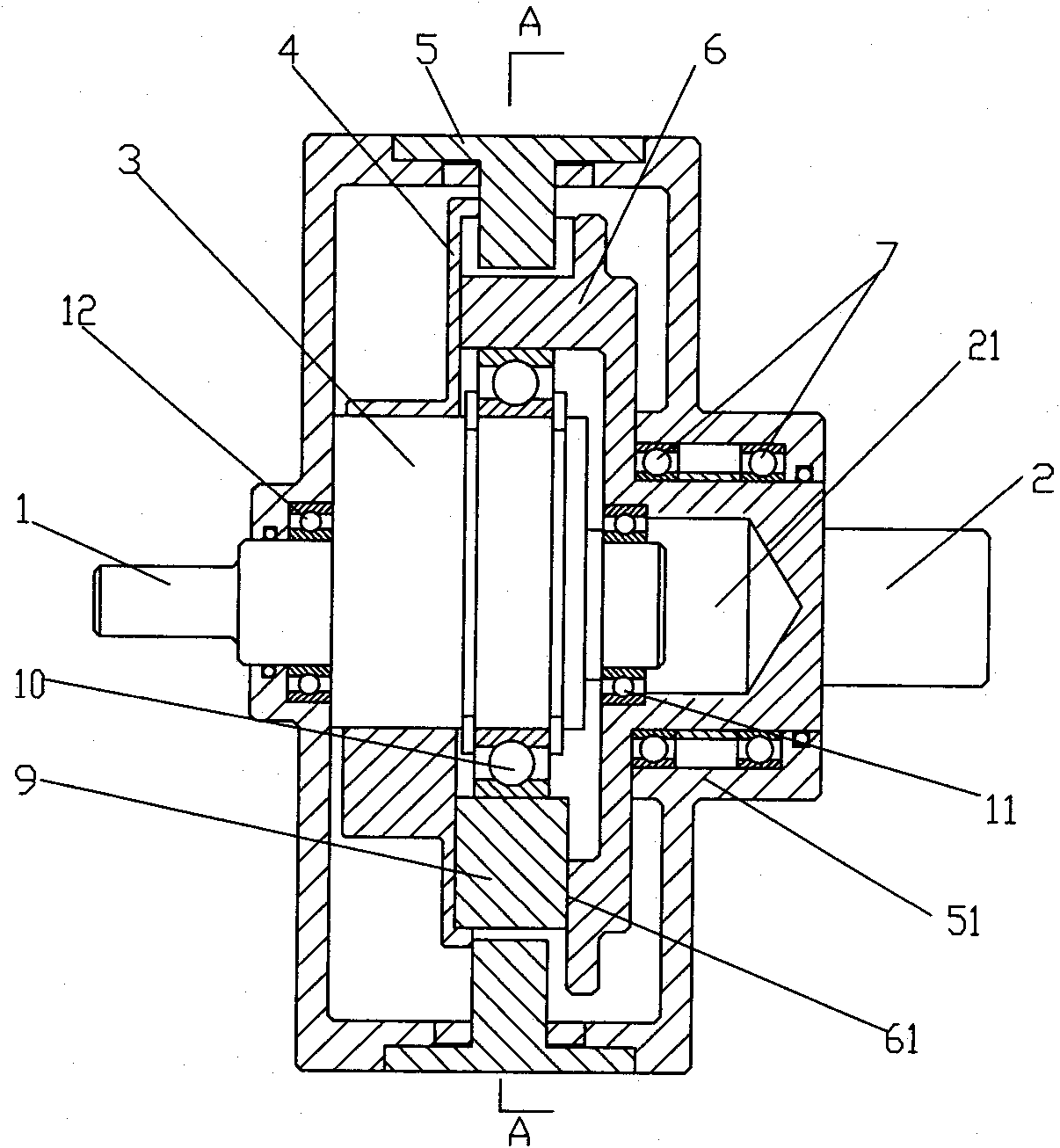

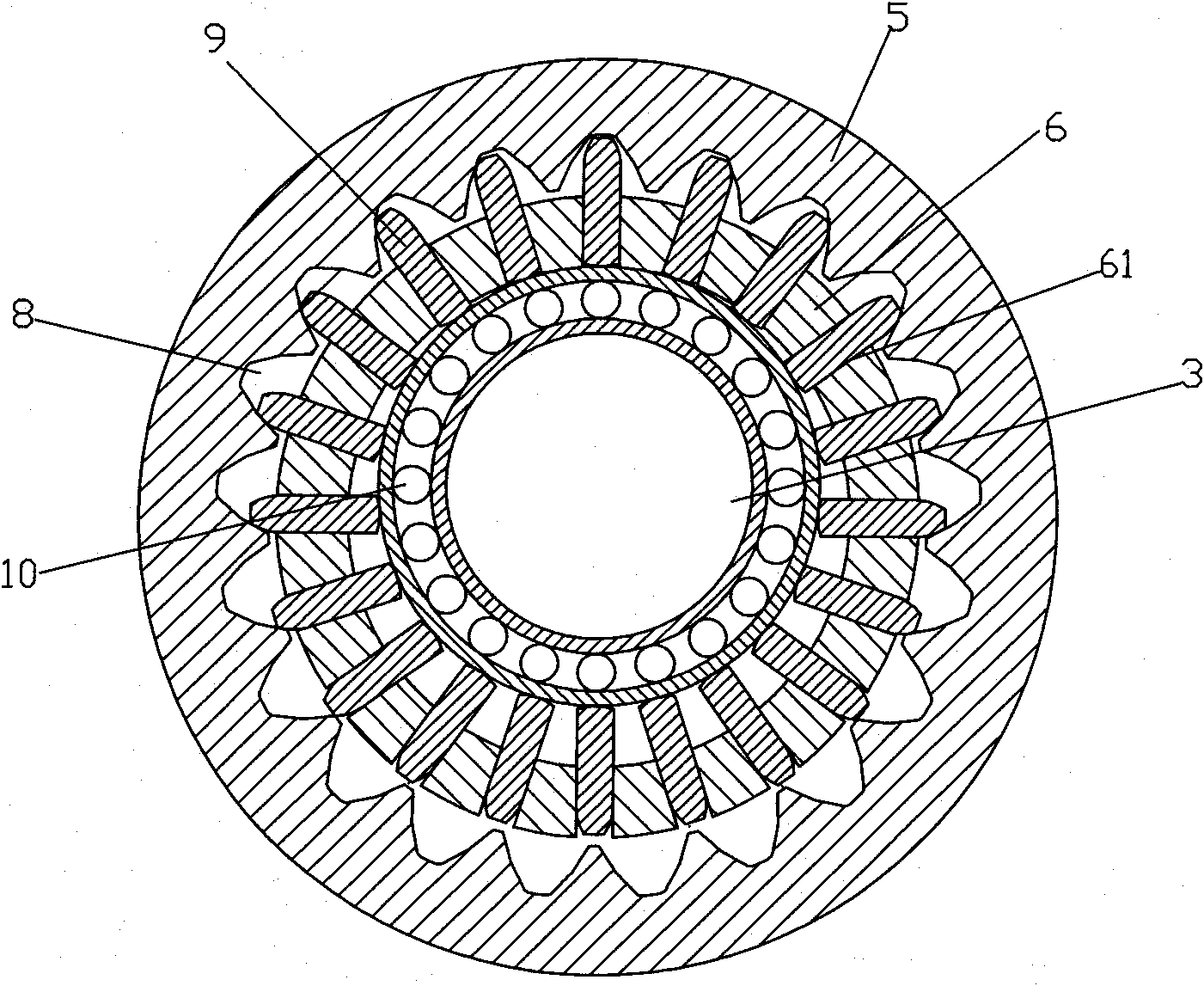

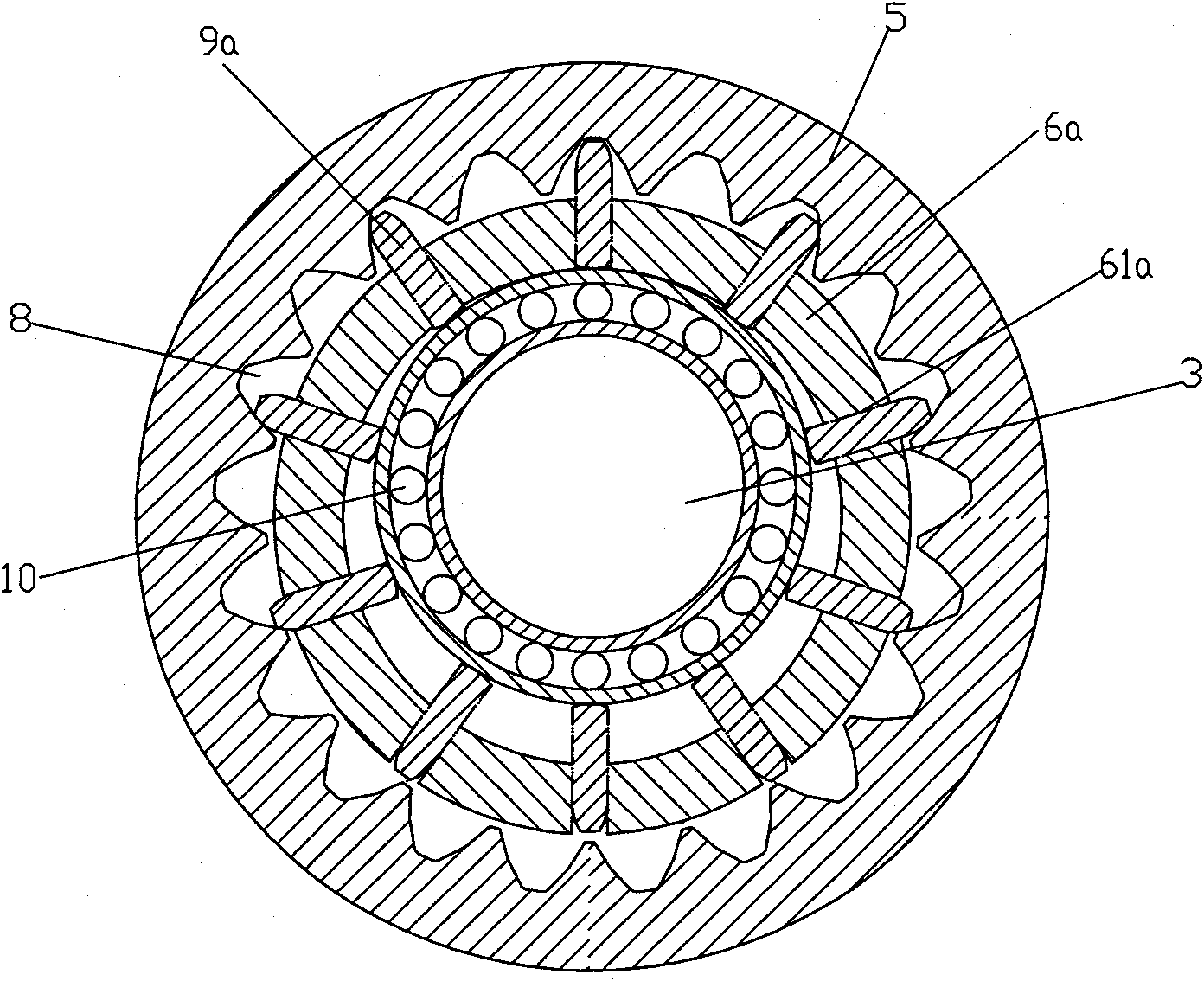

[0019] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 View along the direction of A-A, as shown in the figure: the general reducer with sliding tooth meshing pair in this embodiment includes a housing 5, a power input shaft 1 and a power output shaft 2, and the power input shaft 1 is fixedly arranged with an eccentric in the circumferential direction. Sleeve 3, the power output shaft 2 is coaxial with it and is fixedly provided with a sliding tooth plate 6 in the circumferential direction, and the sliding tooth plate 6 is provided with a sliding tooth 9 in a manner that can slide along its radial direction with a single degree of freedom, and is fixed on the housing 5 and arranged with The power input shaft 1 is concentric and can mesh with the sliding tooth 9 with a small tooth difference. The width of the tooth groove 8 in the circumferential direction is greater than the tooth thickness of the sliding tooth 9 in the circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com