Coating and nano compound thermal-insulation tube sleeve

A nano-composite, thermal insulation pipe sleeve technology, applied in the direction of heat preservation, pipeline protection through thermal insulation, pipeline protection, etc., can solve the problems of unsightly appearance, leakage of the pipe sleeve and casing, loss of large heat, etc., so as to facilitate daily maintenance. , the use of convenient and reliable, the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

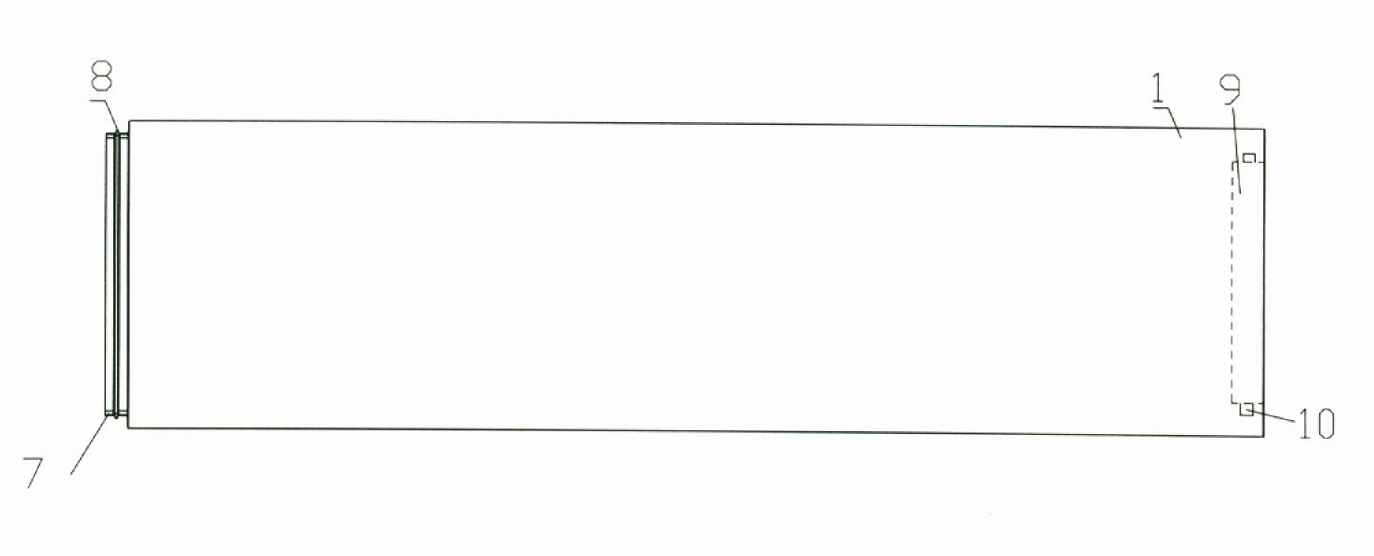

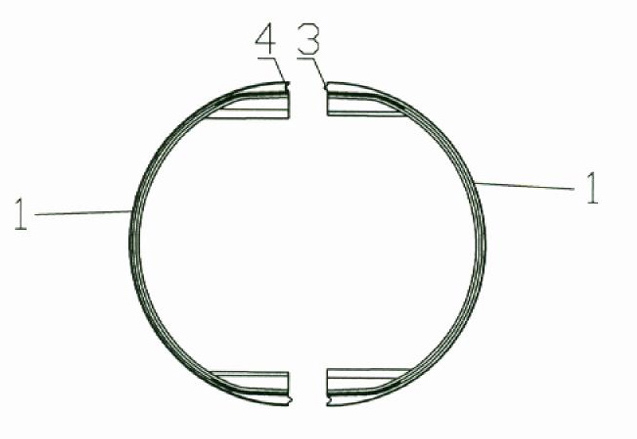

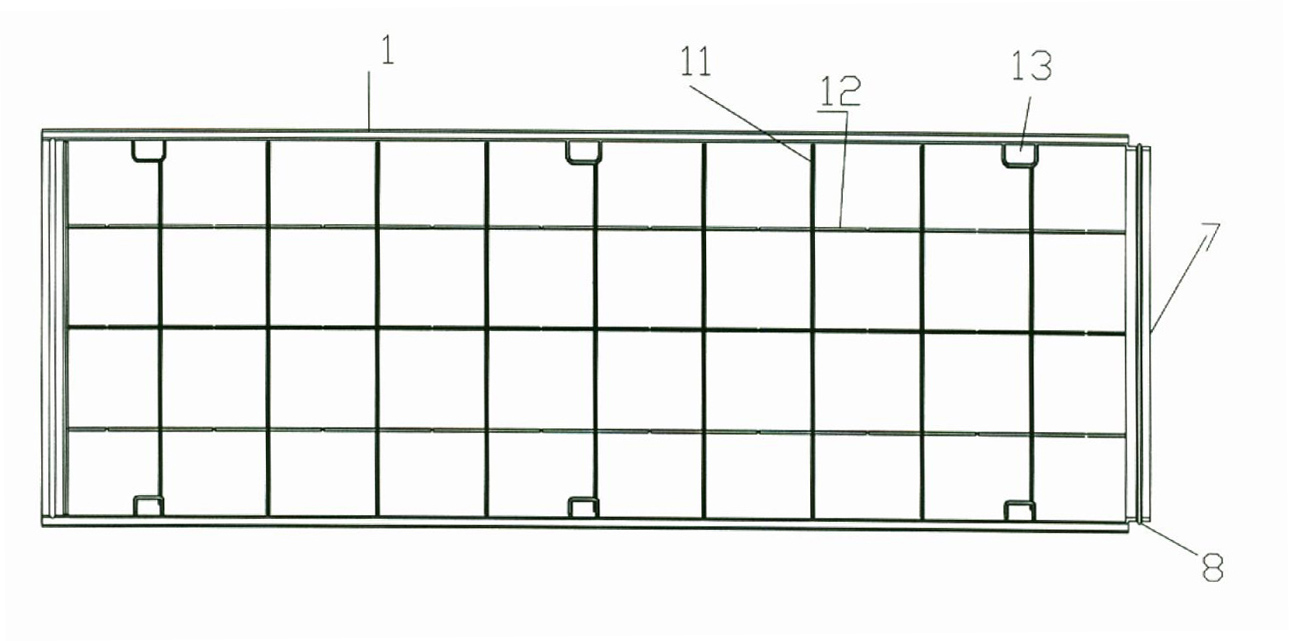

[0013] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown in -4, the present invention includes two half shells 1 that can be spliced together into a complete pipe sleeve body, and at least one layer of insulation layer 2 is respectively arranged on the inner walls of the two half shells 1, and the two half shells 1 The upper and lower joints of the upper and lower shells, the end faces of half of the shell joints are longitudinal waterproof ribs 3, and the end faces of the other half of the shell joints are longitudinal waterproof grooves 4 that match with them, and the two are fitted and connected to each other. Therefore, it has a better sealing and rainproof effect, see figure 2 Shown; The inner walls of the two halves of the shell in the at least one layer of insulation layer 2 are coated with a layer of fireproof paint layer 5 and form a composite insulation layer.

[0014] Figure 4 As shown, the ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com