Remanufactured part surface coating accelerated wear life testing machine and detection method thereof

A technology of surface coating and wear life, which is applied in the field of testing machines, can solve the problems of no coating acceleration, accelerated wear life, inability to accurately judge, etc., and achieve the effect of compact structure and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

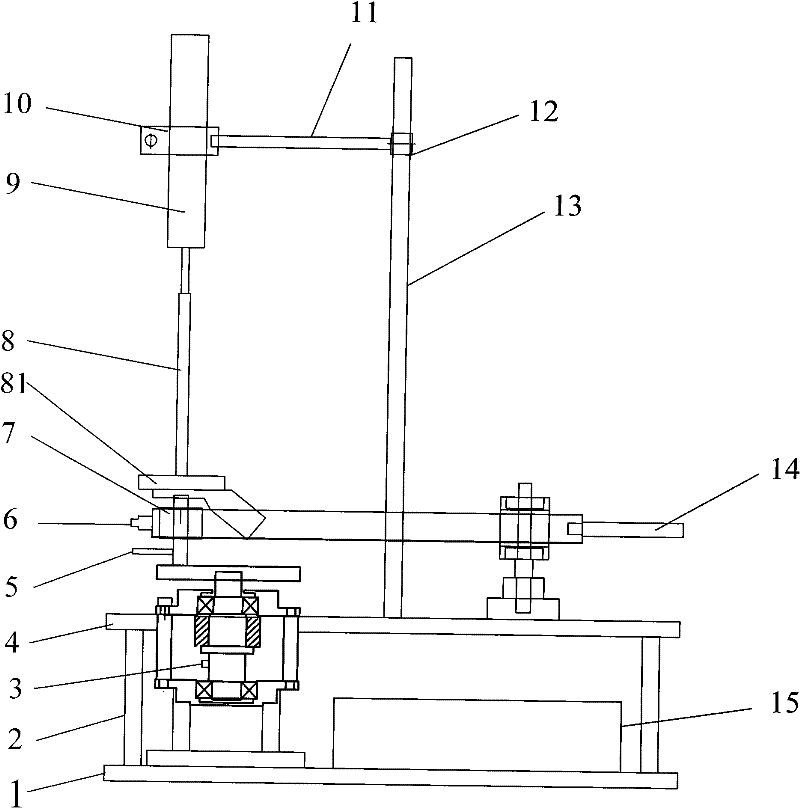

[0040] Such as Figures 1 to 4 As shown, a remanufactured component surface coating accelerated wear life testing machine, the testing machine includes a friction drive part, a degree of freedom loading part and a signal test acquisition part;

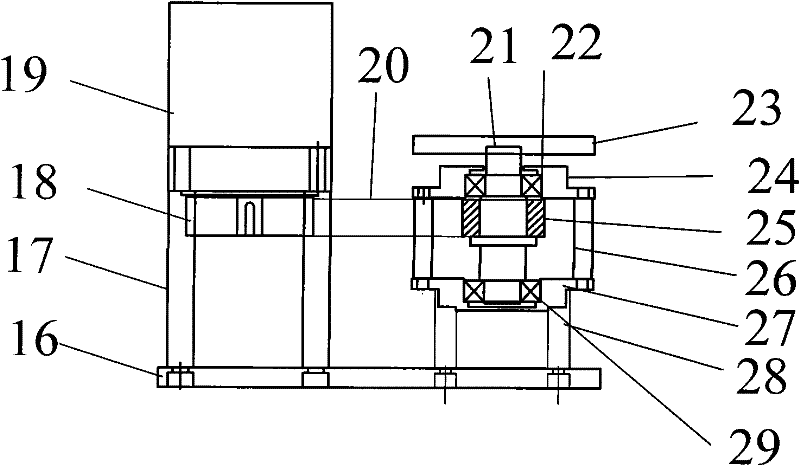

[0041] The friction driving part is located between the upper top plate 4 and the lower bottom plate 1 (the upper top plate 4 and the lower bottom plate 1 are connected through the box bracket 2) including a motor drive system 15 to control the driving drive motor 19, the drive motor 19 is supported by the motor support 17 and placed On the bottom plate 16 of the friction pair; the driving motor 19 drives the driving wheel 18 to rotate, the driving wheel 18 and the driven wheel 25 are connected by a transmission belt 20, the driven wheel 25 is set outside the friction auxiliary main shaft 21 and drives it to rotate, the friction auxiliary main shaft 21 The upper end is provided with an upper bearing 22, and the lower end is provided wi...

Embodiment 2

[0067] Embodiment 2 Specific application example

[0068] In this specific embodiment, a high-velocity arc sprayed 3Cr13 coating is used as an experimental coating.

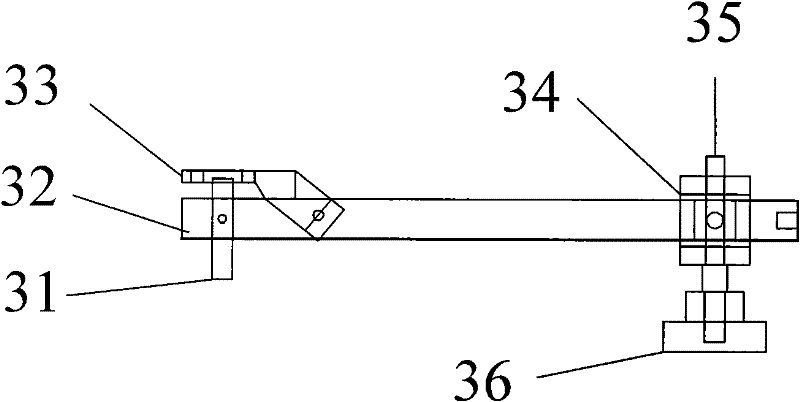

[0069] Before the experiment, according to the test requirements, the surfaces of the counter-grinding disc and counter-grinding pin to be detected were processed into planes, and then the 3Cr13 coating was sprayed on the bottom surface of the counter-grinding pin by high-speed arc spraying equipment, and the coating was kept at a certain level by grinding. thickness. Put the grinding pin into the front section of the loading lever and fix it with a nut, start the motor to adjust the speed, then load, start the signal acquisition device. The driving wheel of the variable frequency motor drives the small driven wheel and the friction sub-spindle to rotate through the transmission belt, and transmits the speed signal to the speed sensor.

[0070] According to the test requirements, when performing the dry frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com