Solar cell and method for manufacturing solar cell

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., which can solve problems such as reduced conversion efficiency, ineffective solar cell functions, and increased non-power generation areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0035] Hereinafter, 1st Embodiment which actualized this invention is demonstrated referring drawings. In addition, in order to make each member in each drawing a size that can be seen on each drawing, the amount of reduction is different for each member and is shown in the drawing.

[0036] (Structure of solar cell)

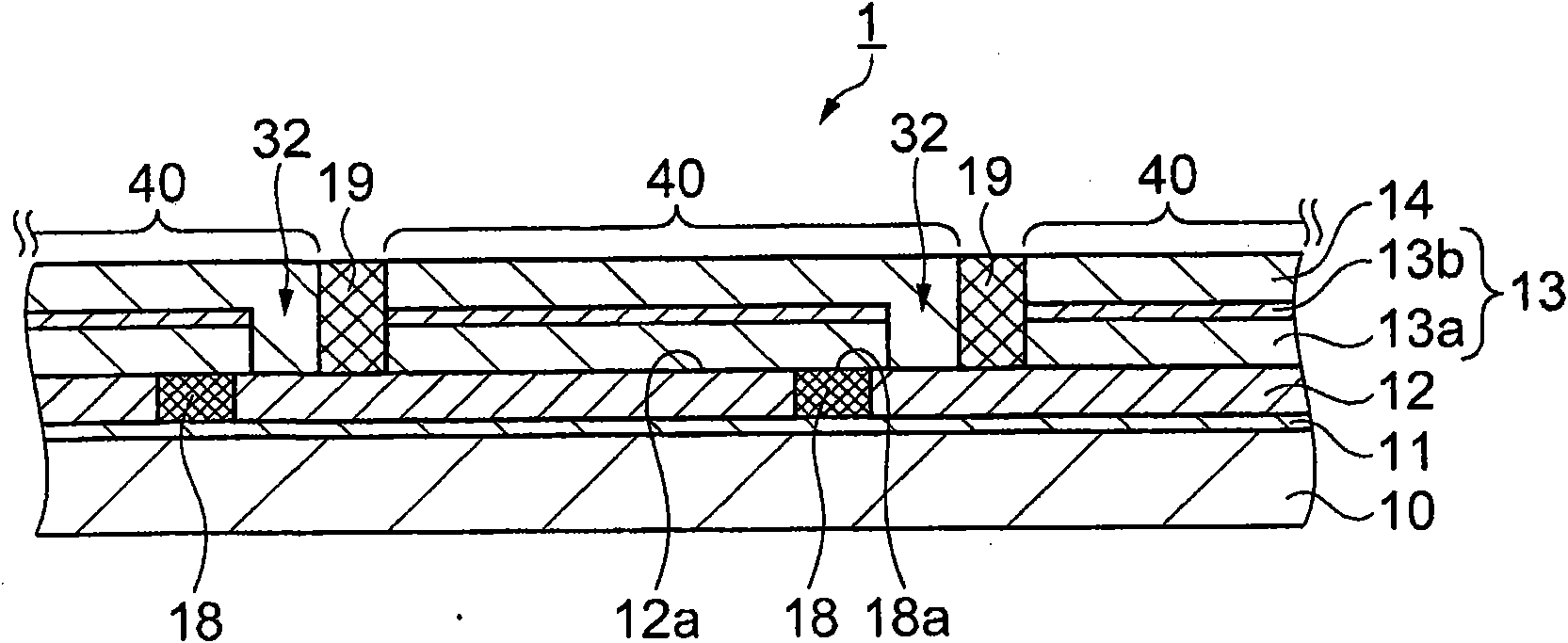

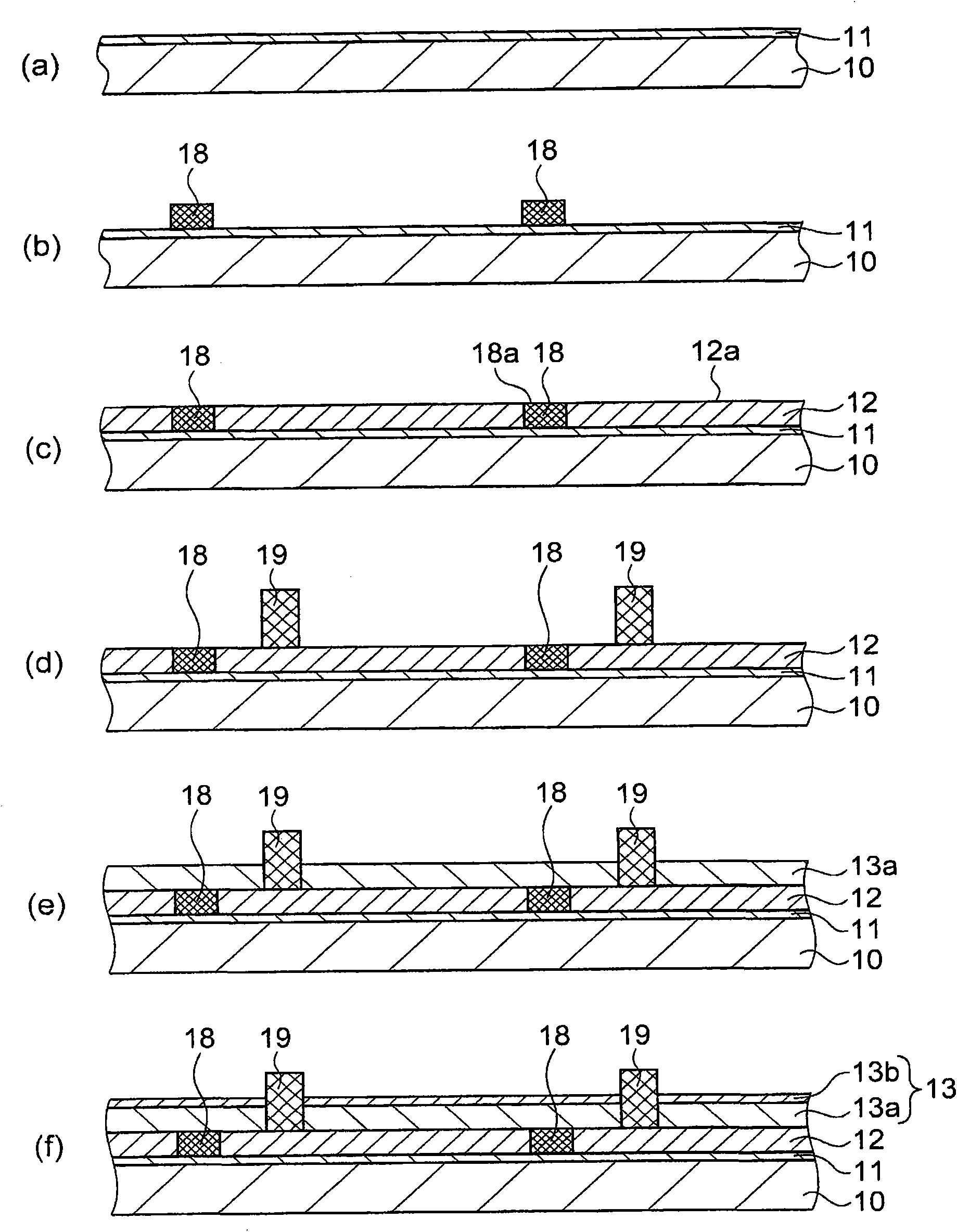

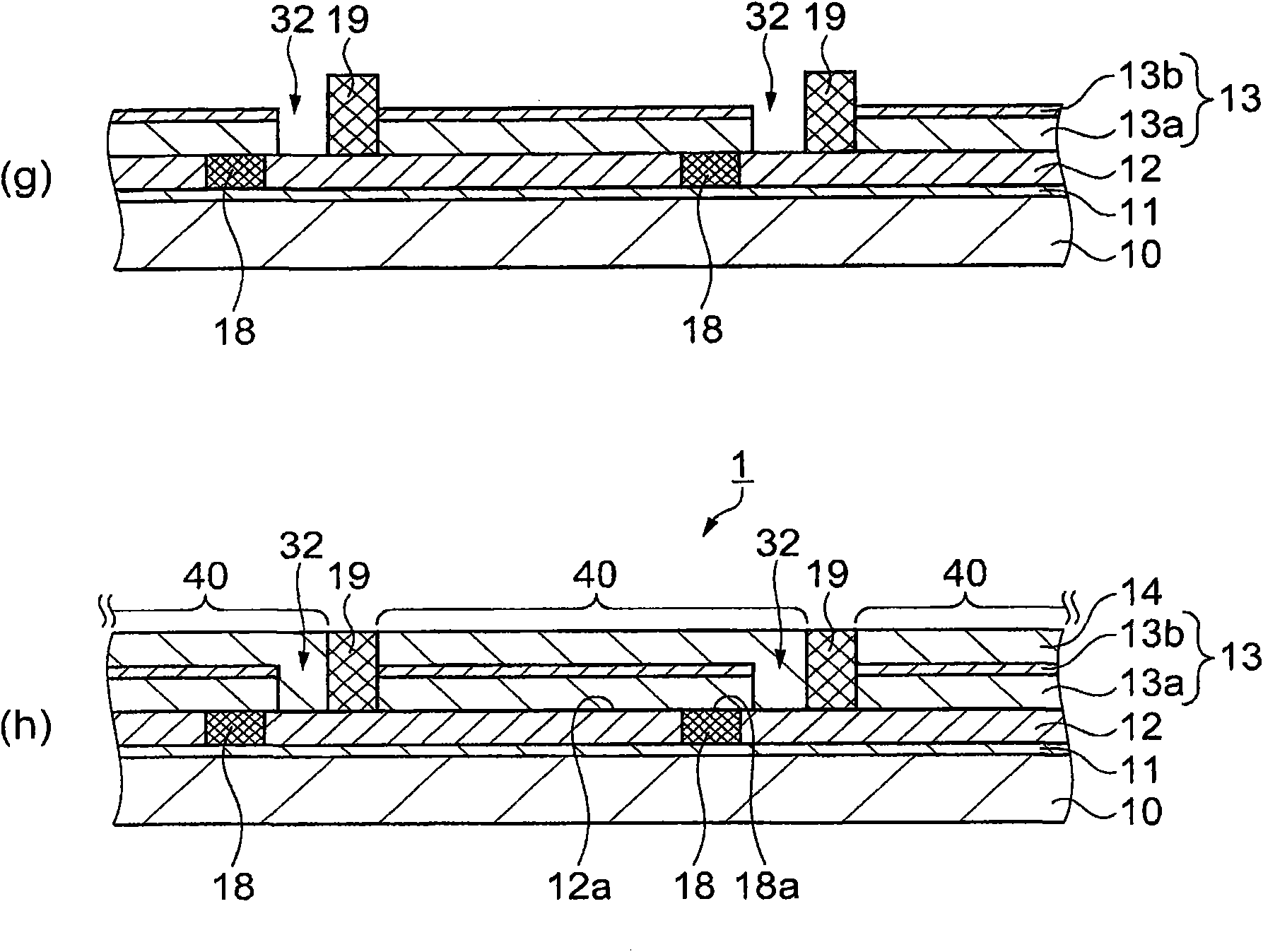

[0037] First, the structure of the solar cell will be described. In addition, in this embodiment, the configuration of a CIGS type solar cell will be described. figure 1 is a cross-sectional view showing the structure of the solar cell of the present embodiment.

[0038] Such as figure 1 As shown, the solar cell 1 is composed of an assembly of battery cells 40, and the battery cell 40 includes a substrate 10, a base layer 11 formed on the substrate 10, a first electrode layer 12 formed on the base layer 11, and a base layer 12 formed on the first The semiconductor layer 13 on the electrode layer 12 and the second electrode layer 14 formed on the semiconducto...

no. 2 Embodiment approach

[0066] Hereinafter, the second embodiment will be described with reference to the drawings. In addition, in order to make each member in each drawing a size that can be seen on each drawing, the amount of reduction is different for each member and is shown in the drawing.

[0067] (Structure of solar cell)

[0068] First, the structure of the solar cell will be described. In addition, in this embodiment, the configuration of a CIGS type solar cell will be described. Figure 4 is a cross-sectional view showing the structure of the solar cell of the present embodiment.

[0069] Such as Figure 4 As shown, the solar cell 1a is composed of an assembly of battery cells 40, and the battery cell 40 includes a substrate 10, a base layer 11 formed on the substrate 10, a first electrode layer 12 formed on the base layer 11, and a base layer 12 formed on the first electrode layer. The semiconductor layer 13 on the electrode layer 12 , the second electrode layer 14 formed on the semic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com