Lithium niobate film electro-optical modulator and preparation method thereof

An electro-optic modulator, lithium niobate technology, applied in the field of optical communication, can solve the problems of high cost, large electrode spacing, and affecting the performance of the modulator, and achieve the effect of increasing the overlapping area, reducing the process cost, and increasing the effective refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

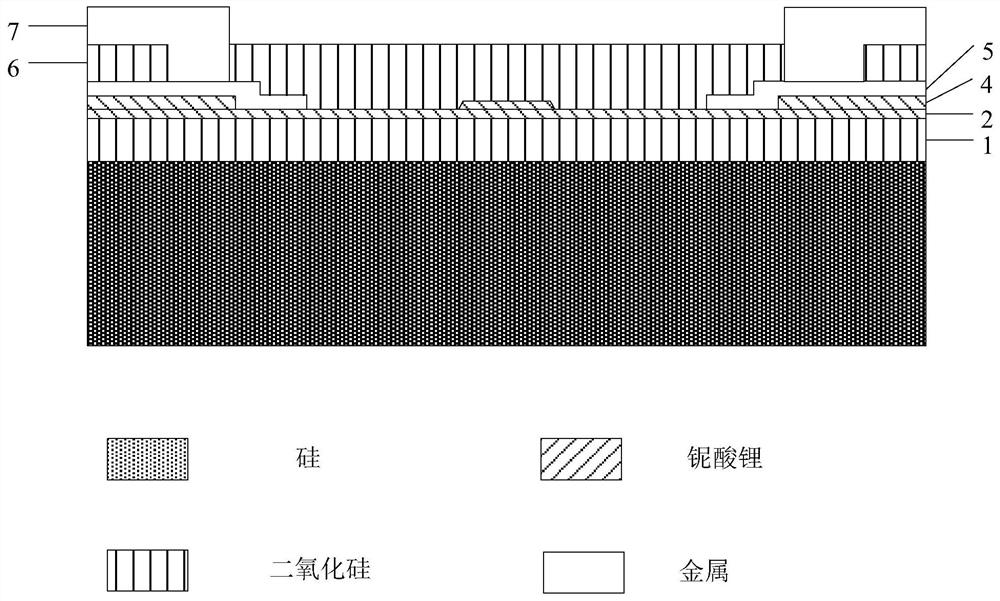

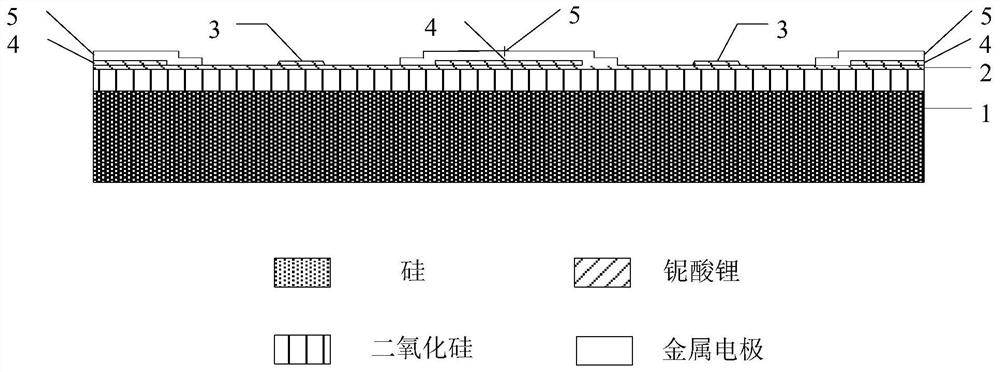

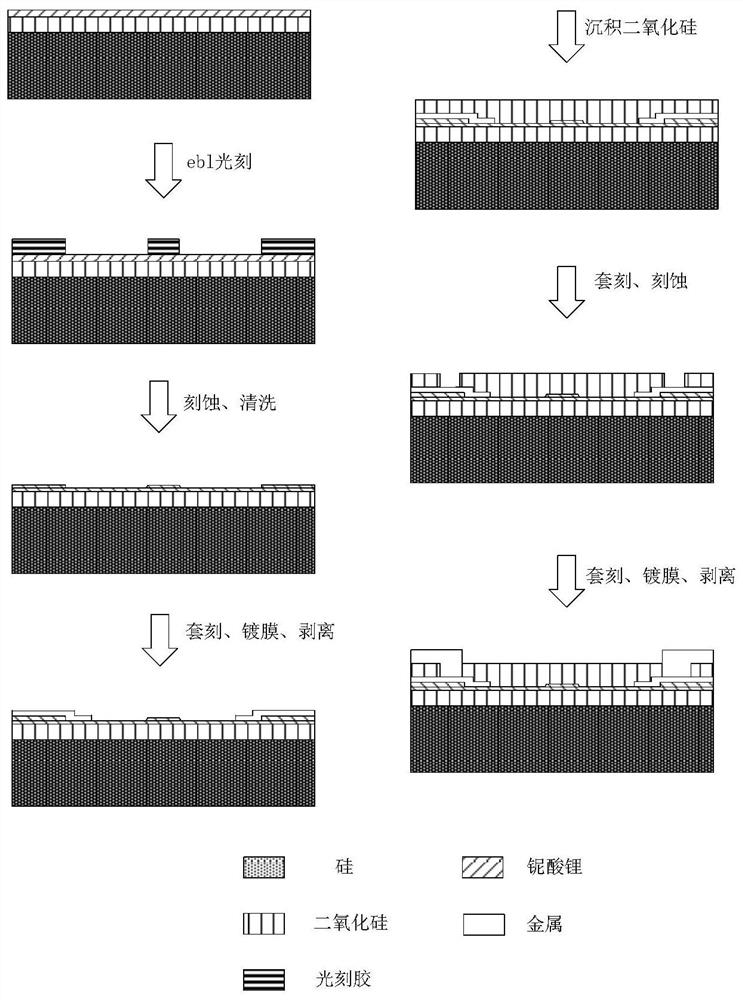

[0039] Such as figure 1 As shown, this embodiment includes a substrate wafer 1, a lithium niobate thin film substrate 2, a lithium niobate optical waveguide 3, a lithium niobate thin film lining 4, a traveling wave electrode 5, a protective layer 6 and an extraction electrode 7. The extraction electrode 7 is connected to the traveling wave electrode 4 . Among them, the traveling wave electrode structure in the lithium niobate thin film electro-optic modulator is as follows figure 2 There are three traveling-wave electrodes 5 as shown, which are respectively located on both sides and the center above the lithium niobate film substrate 2, and the lithium niobate film lining 4 is located between the lithium niobate film substrate 2 and the traveling-wave electrode. 5, the area of the traveling wave electrode 5 is larger than the area of the lithium niobate thin film lining 4 so as to completely cover the lithium niobate thin film lining 4.

[0040] The specific implementat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com