High-frequency rotary connector

A rotary connector, high-frequency technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve problems such as distortion of the transmission signal of the slip ring, and achieve a simple and reasonable structure, low cost, and solve serious distortion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

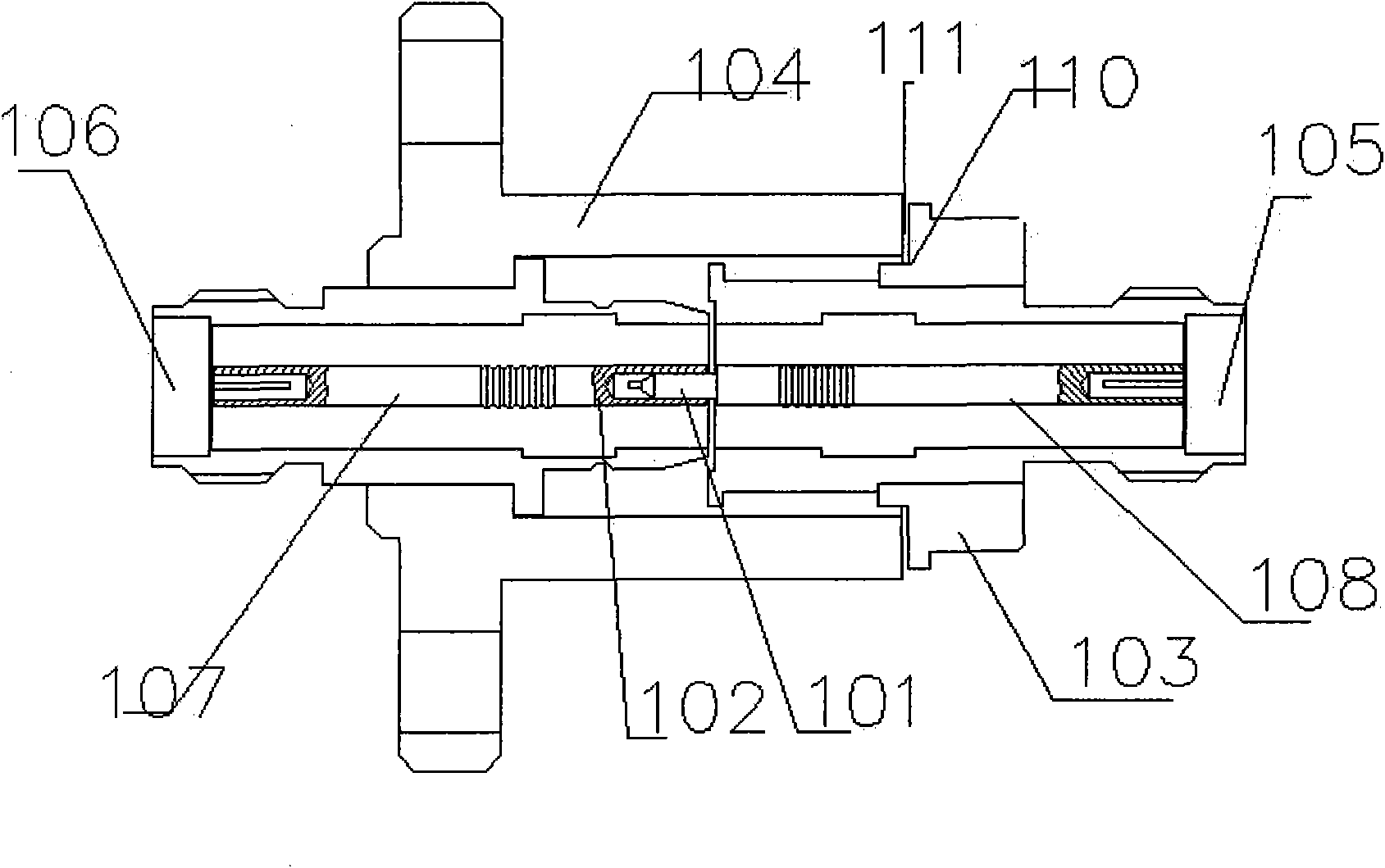

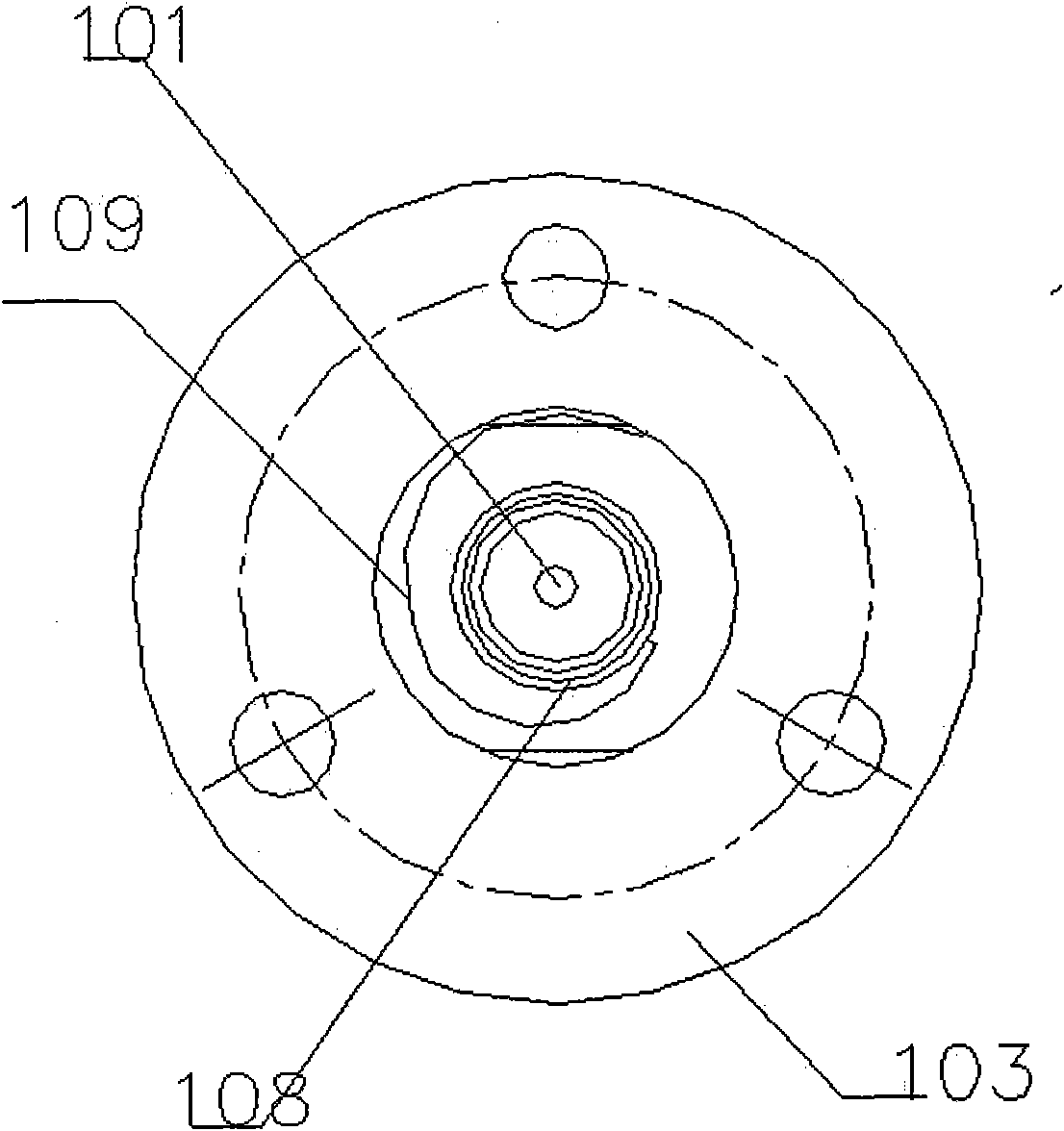

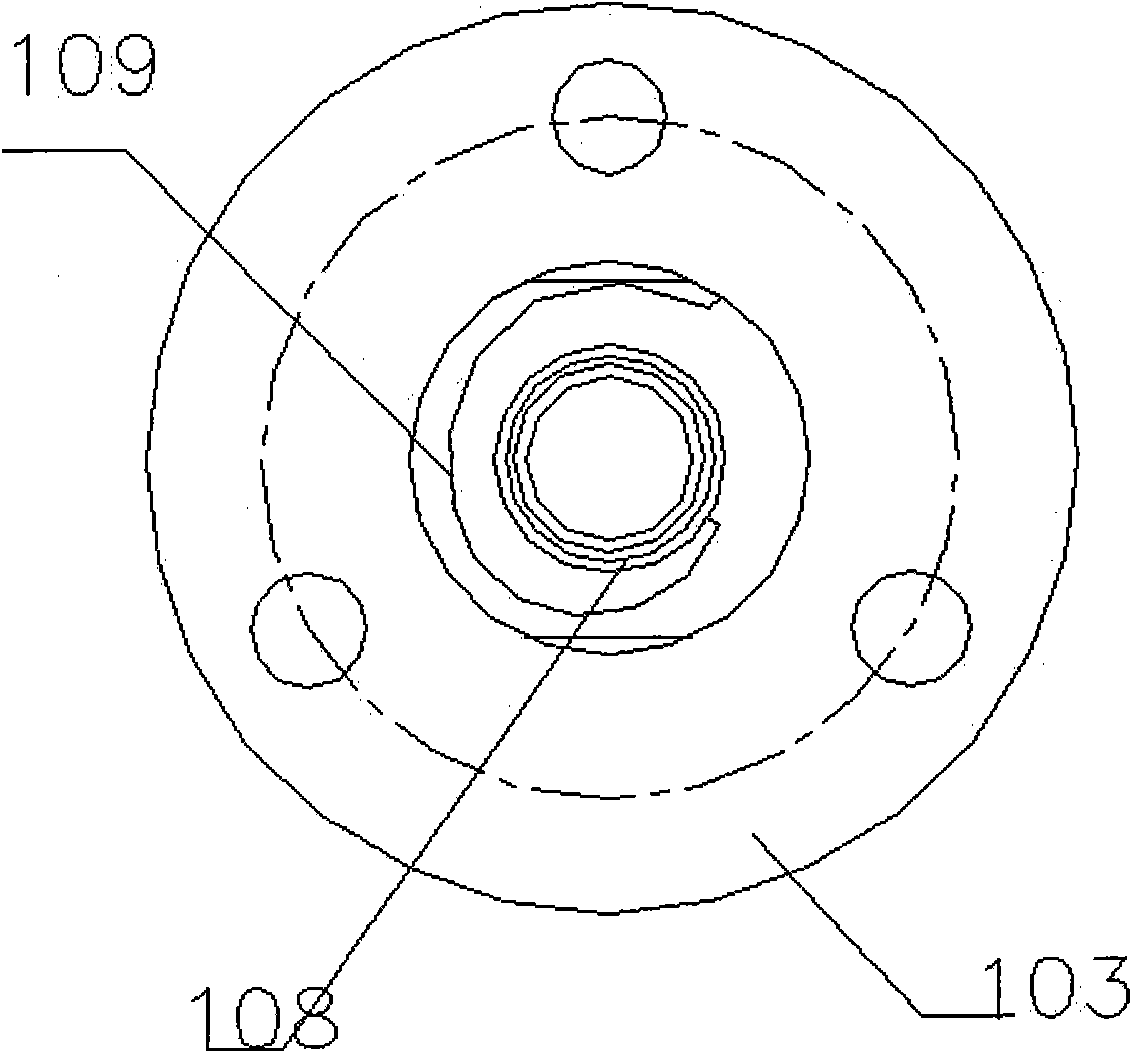

[0019] A high-frequency rotary connector consists of 101-rotor top shaft; 102-stator groove; 103-rotor shell; 104-stator shell; 105-rotor SAM card slot; 106-stator SAM slot; 107-stator inner shaft 108-rotor inner shaft; 109-rolling connection device; 110-rotor shell notch; 111-stator shell convex.

[0020] Connect the fixed equipment signal transmission line socket to the 106-stator SAM slot, and the signal is transmitted to the 107-stator inner shaft and to the 102-stator groove through the 109-rolling connection device to 101 with the 109-rolling connection device -Rotor top shaft, the signal is transmitted to 101-rotor top shaft and connected to 108-rotor inner shaft, 108-rotor inner shaft is connected to 106-stator SAM slot, 106-stator SAM slot is connected to the rotating body, the signal is It is transferred from the fixed device to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com