Method for manufacturing multilayer flexible printed wiring board and multilayer circuit matrix material

A base material, flexible printing technology, applied in the direction of printed circuit, multilayer circuit manufacturing, and the formation of electrical connection of printed components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

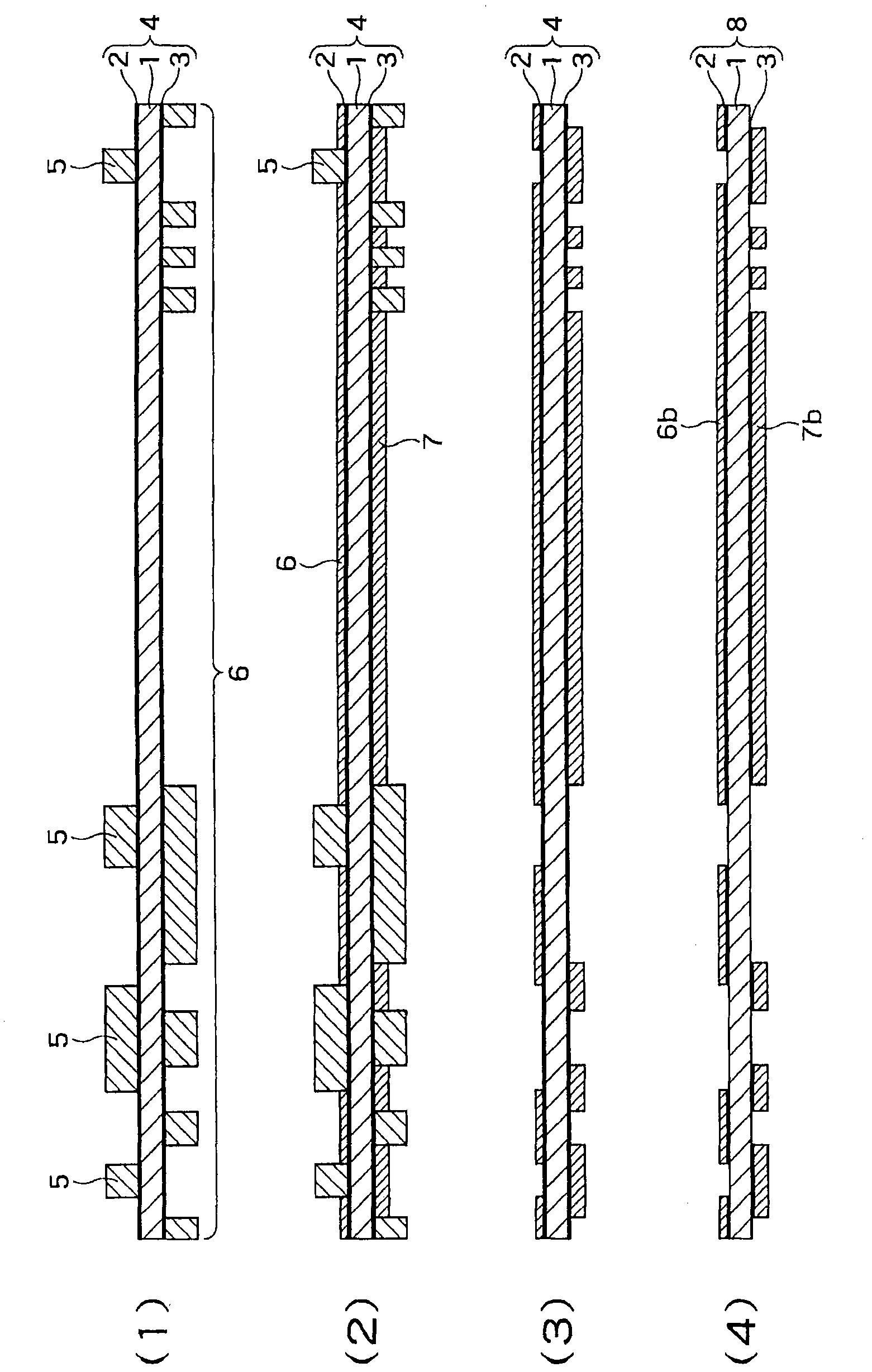

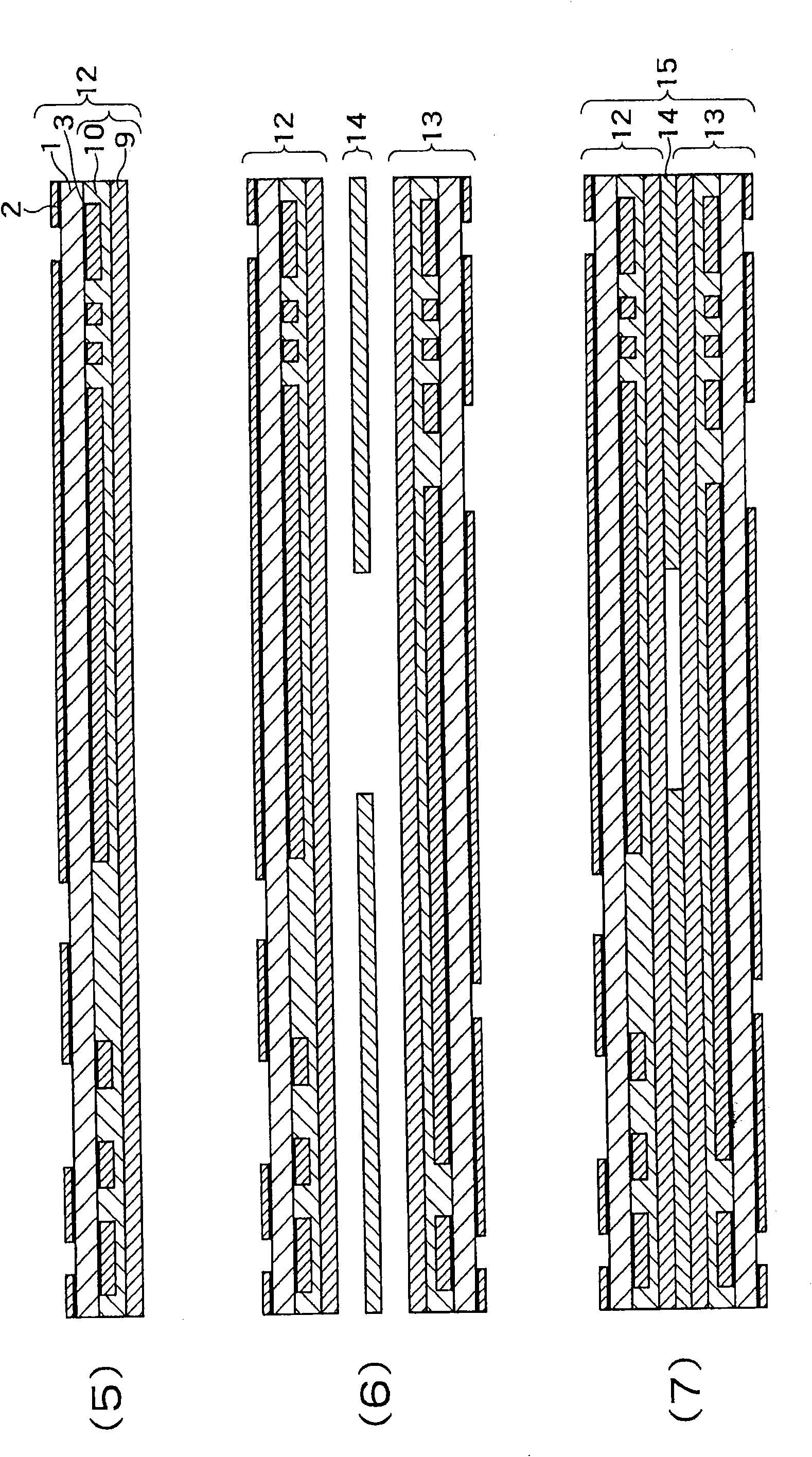

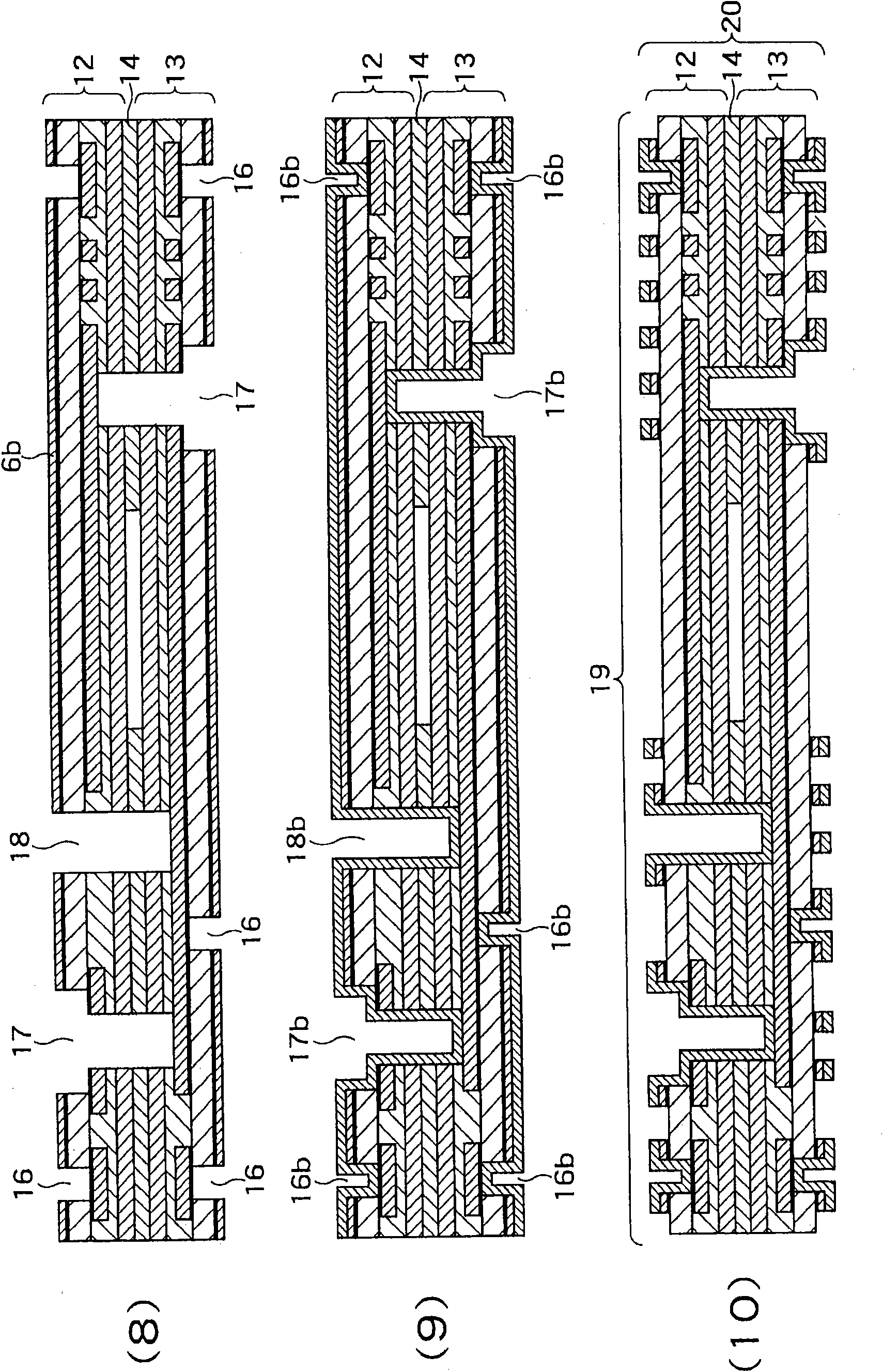

[0052] Figure 1A to Figure 1C It is a sectional structural view showing the manufacturing method of the wiring board of this invention.

[0053] First, if Figure 1A As shown in (1), prepare a double-sided circuit having copper films 2 and 3 with a thickness of 0.3 μm on both sides of a flexible insulating base material 1 (here, polyimide with a thickness of 12.5 μm) such as polyimide. Base material 4.

[0054] The thickness of the copper thin film is preferably 0.1 to 0.5 μm. When the thickness is less than 0.1 μm, film defects such as pinholes (pin holes) are likely to occur on the copper foil film, which adversely affects the formation of subsequent circuit patterns.

[0055] In addition, when it is thicker than 0.5 μm, when the circuit pattern is formed by a semi-additive method using the copper foil film as a seed layer, and then the seed layer is removed, the film of the circuit pattern is reduced due to etching and removal for each circuit pattern. If it is too lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com