Sheet-type secondary battery and manufacturing method therefor

A secondary battery and manufacturing method technology, which is applied in secondary battery manufacturing, secondary batteries, batteries, etc., can solve problems such as electrode peeling and short circuit, obstacles to large-capacity laminar secondary batteries, and difficult welding conditions, etc., to achieve Effective in suppressing damage and making it easier to increase capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

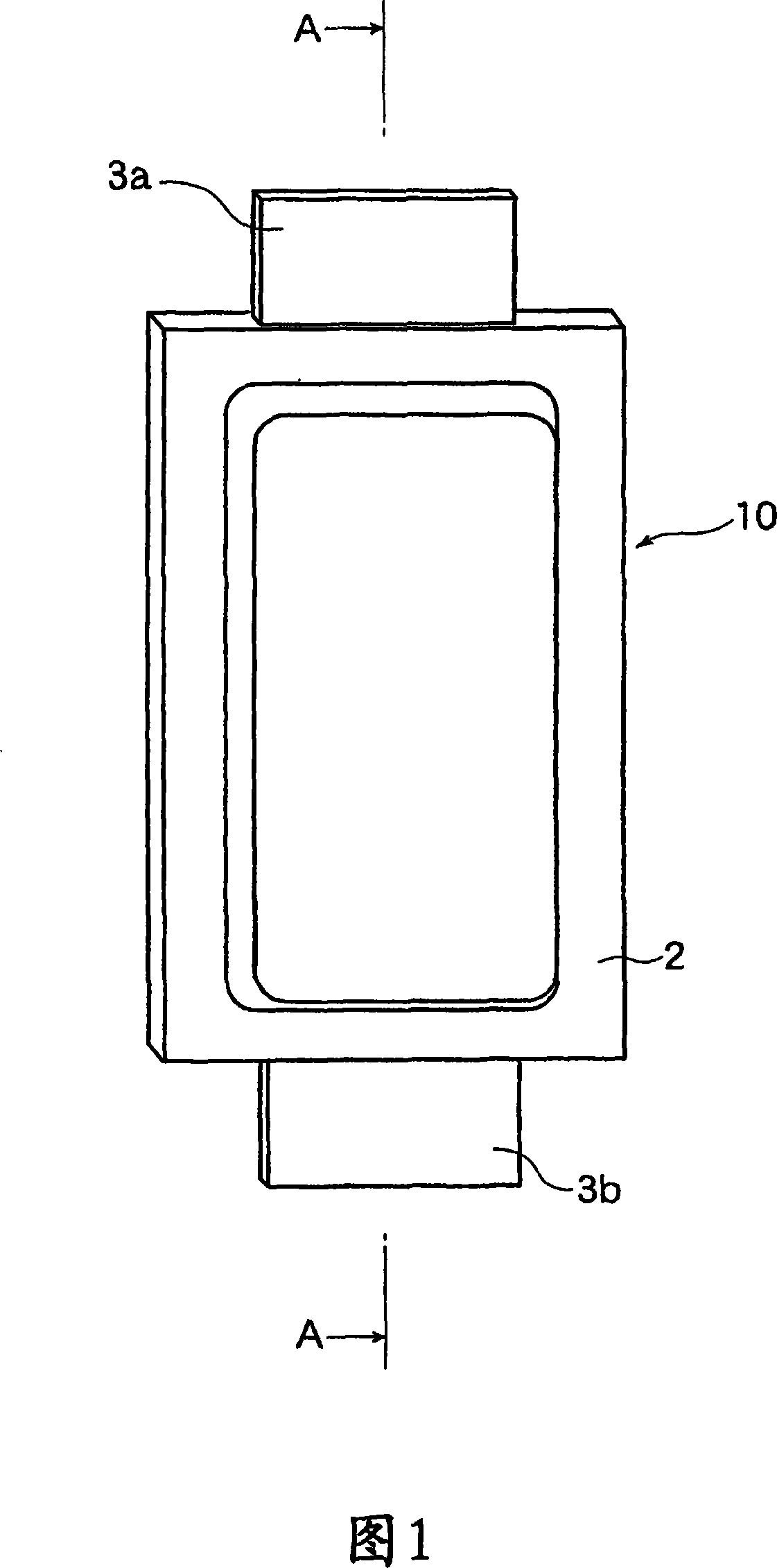

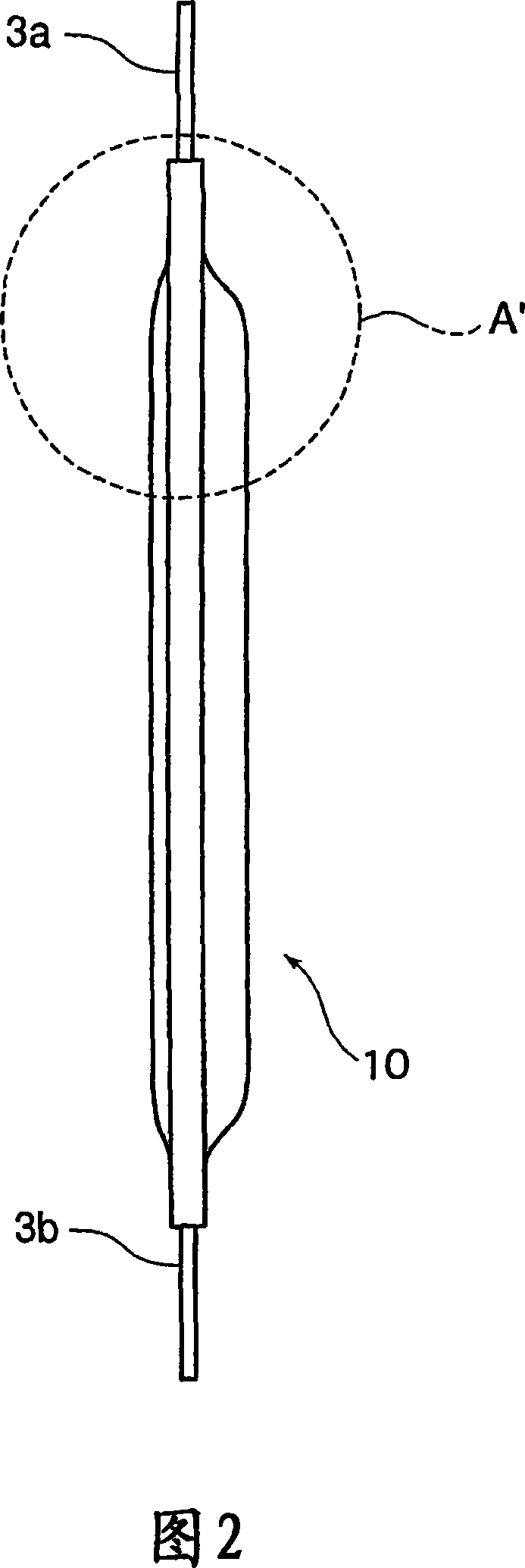

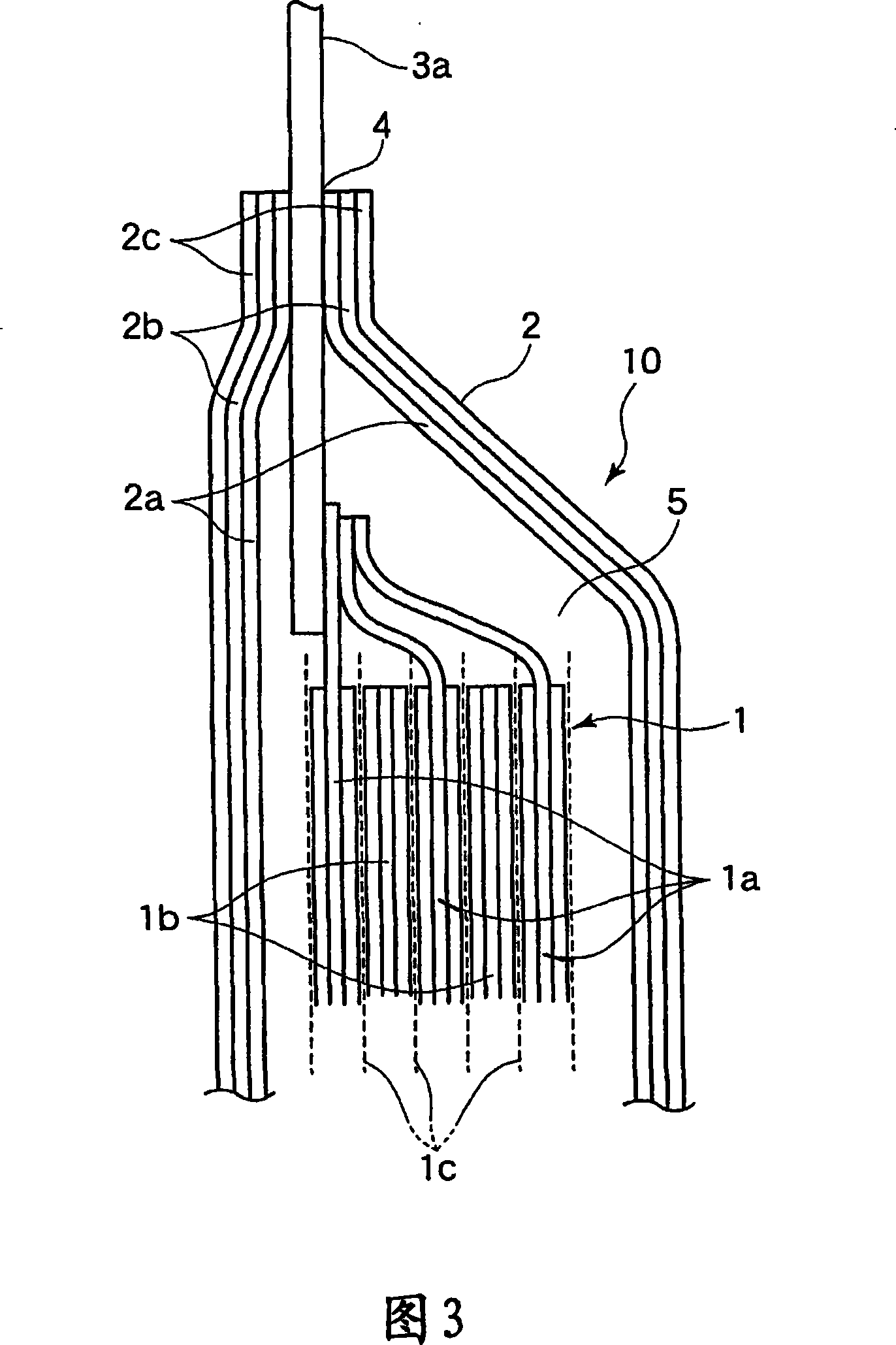

[0054] Hereinafter, an embodiment of the present invention will be described with reference to FIGS. 1 to 4 . Here, FIG. 1 is a perspective view schematically showing an example of a sheet-shaped secondary battery of the present invention, and FIG. 2 is a left side view of FIG. 1 . In addition, FIG. 3 is an A-A sectional view of FIG. 1, which is an enlarged view showing a portion surrounded by a circle A' in FIG. 2, and FIG. 4 is a schematic diagram for explaining a pair of internal electrodes.

[0055] In FIGS. 1 to 3 , 10 is a sheet-shaped lithium ion secondary battery (sheet-shaped secondary battery), and a flexible bag-shaped outer casing 2 houses the inner electrode pair 1 and the electrolytic solution 5 in a sealed state. As shown in FIG. 3, the internal electrode pair 1 is formed by alternately stacking a plurality of sheet-shaped positive electrodes 1a and a plurality of sheet-shaped negative electrodes 1b through separators 1c in a sheet shape. The sheet-shaped posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com