Novel thermal insulation structure on radiant tube heater

A radiant tube heating and radiant tube technology, which is used in thermal insulation, pipeline protection, heat exchange equipment, etc., can solve the problems of thermal expansion and deformation of radiant tube covers, poor thermal insulation performance, and inability to use, and achieves extended service life, good thermal insulation effect, The effect of heat transfer reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

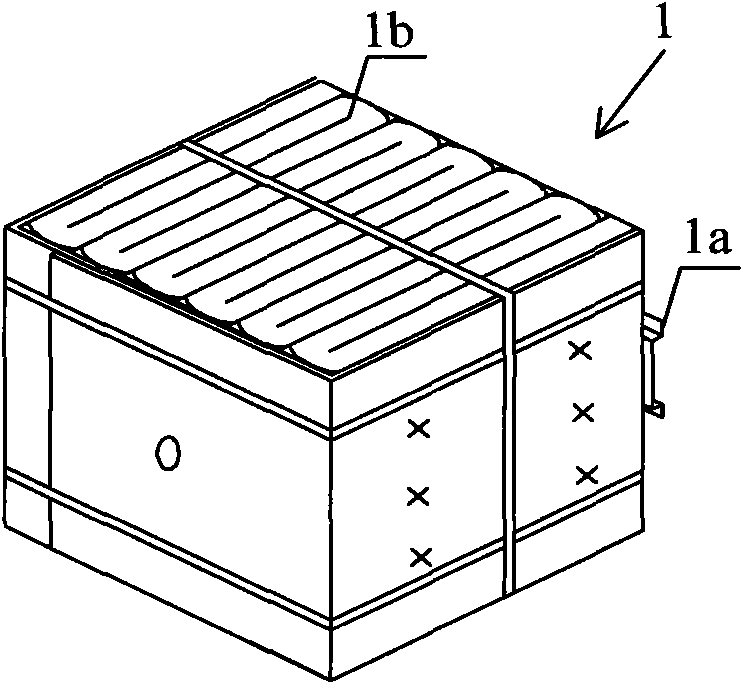

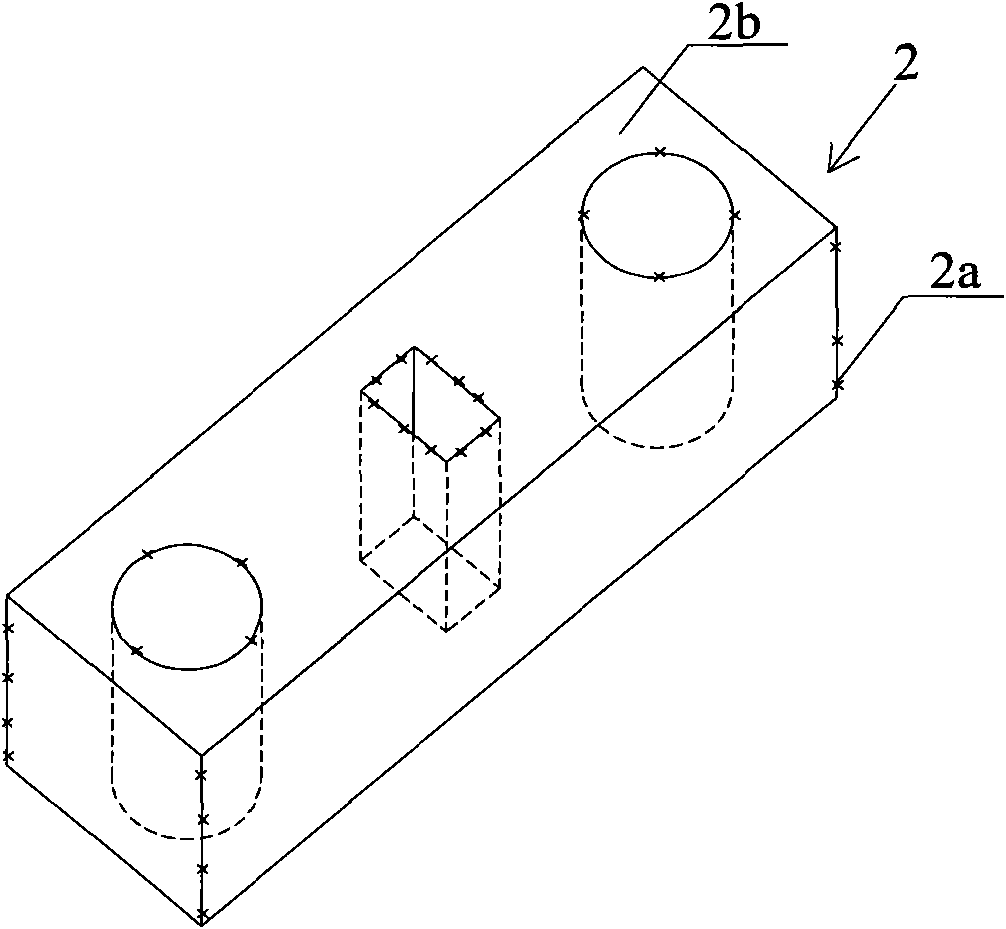

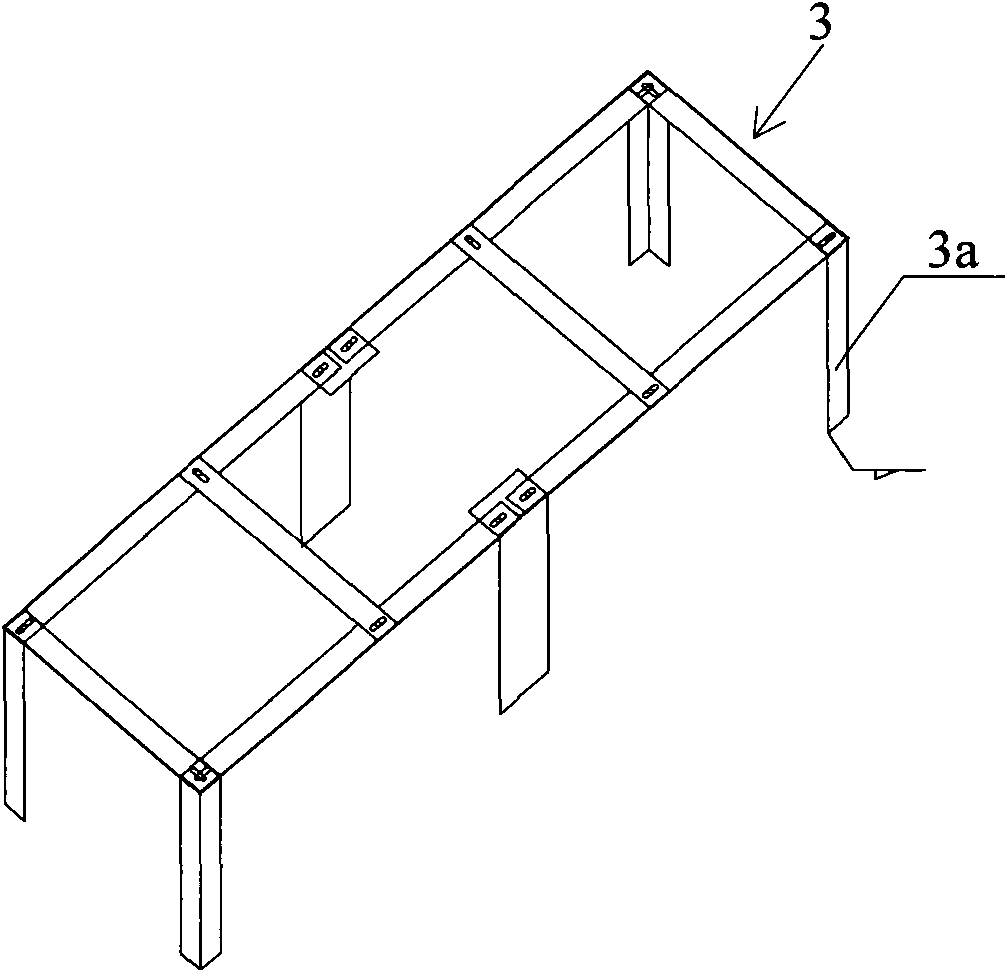

[0018] like Figure 5 The new insulation structure on the radiant tube heating device shown includes a ceramic fiber module 1 , a high temperature resistant slag-free ball fiber cover 2 , an expandable metal frame 3 and a fiber sealing ring 4 . like figure 1 As shown, the ceramic fiber module 1 is folded into a fiber folded unit block 1b by a ceramic fiber blanket according to the module bulk density, and is riveted with a high-temperature-resistant metal rivet 1a. like figure 2 As shown, the high-temperature-resistant slag-free fiber cover 2 is sewn from the slag-free fiber blanket 2b through the ceramic fiber thread 2a, and the thickness of the high-temperature-resistant slag-free fiber cover is 5-20 mm. like image 3 As shown, the expandable metal frame 3 is composed of right-angled and sheet-shaped metal members 3a with long holes and bolts and nuts to form an expandable structure that can move vertically and horizontally under high temperature conditions. like Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com