Fixed bed adsorption reactor

A fixed bed adsorption and reactor technology, applied in chemical instruments and methods, dispersed particle separation, chemical/physical processes, etc., can solve the problems of uneven airflow redistribution, uneven airflow distribution, uneven bed resistance, etc. Good sealing, easy filling, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

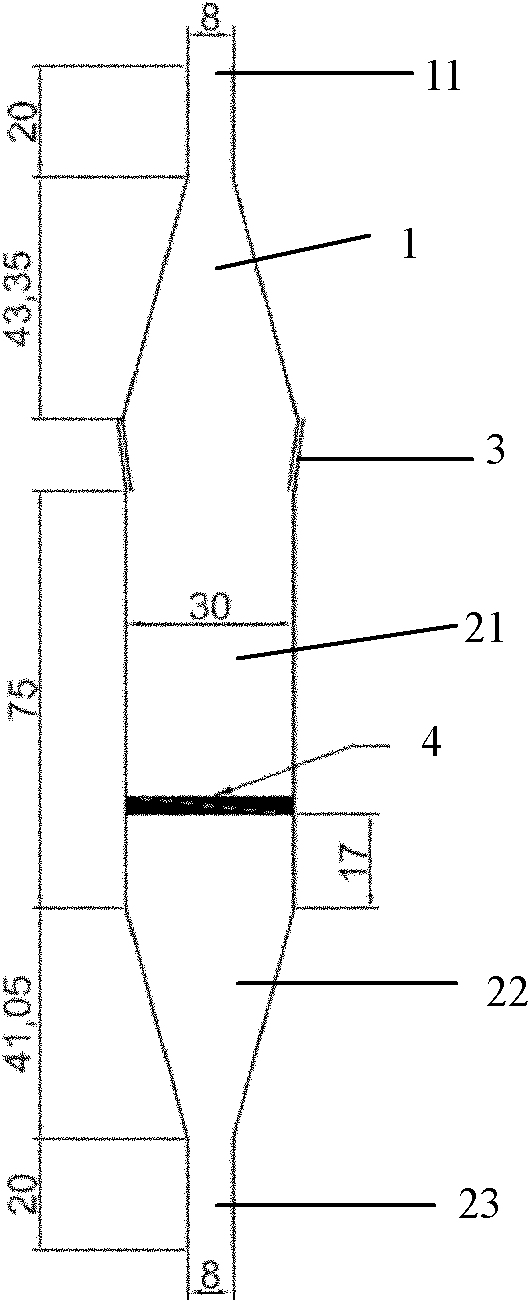

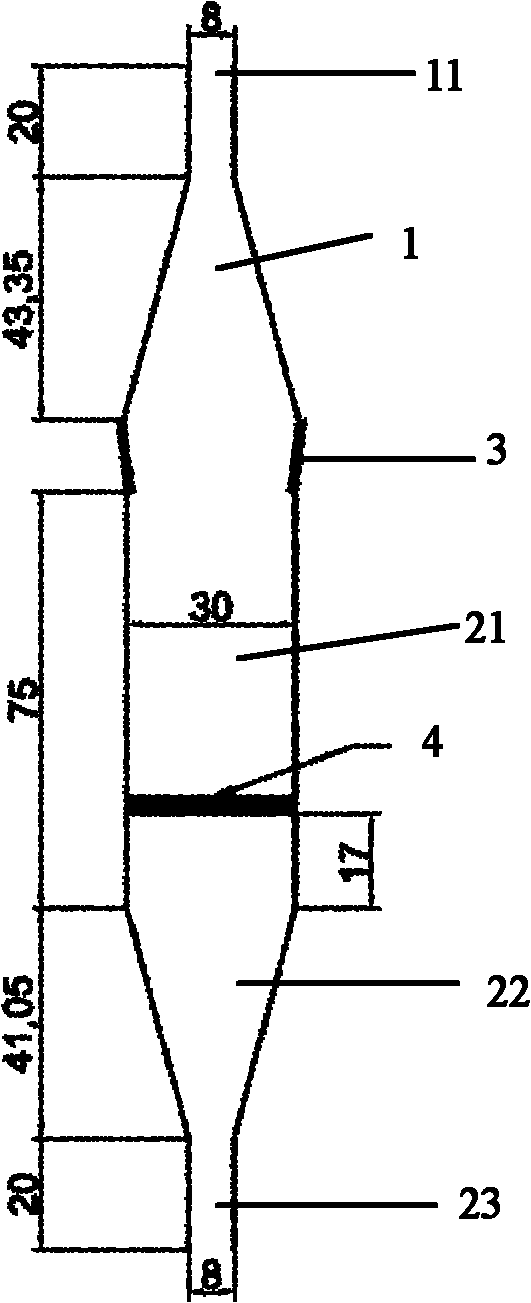

[0018] see figure 1 , the embodiment of the present invention is provided with an upper reactor main body 1 and a lower reactor main body, the upper reactor main body 1 is inserted into the lower reactor main body, the connection between the upper reactor main body 1 and the lower reactor main body adopts a frosted interface 3, and the upper reactor main body The main body 1 is in the shape of a cone, and the top of the upper reactor main body 1 is provided with an air inlet 11, and the diameter reduction angle between the air inlet 11 and the upper reactor main body 1 is 28° to 32°, and the lower reactor main body is provided with a lower cylindrical body 21 And the lower cone 22, the lower cylinder 21 and the lower cone 22 are integrated, the bottom of the lower reactor main body is provided with an air outlet 23, and the diameter reduction angle between the air outlet 23 and the lower reactor main body is 28 ° to 32 °. A sand chip 4 is arranged inside the cylinder body 21 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com