Upper polishing disk of polishing machine

A technique for polishing machines and polishing discs, which is applied in abrasives, metal processing equipment, manufacturing tools, etc. It can solve the problems of no temperature control and uncontrollable changes in the temperature of polishing discs, etc., and achieve a reliable cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

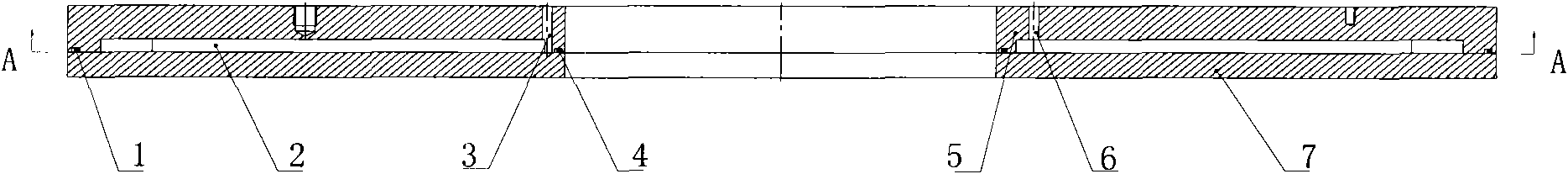

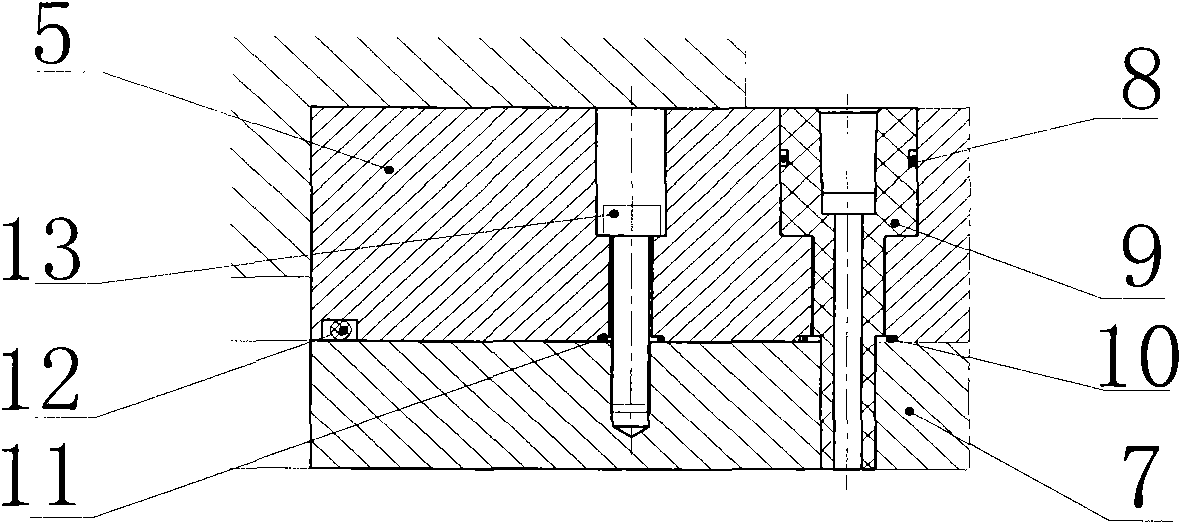

[0018] Example 1: see figure 1 , figure 2 , image 3 , an upper polishing disc of a polishing machine, including an upper disc working disc 7, an upper disc water cooling disc 5 is arranged above the upper disc working disc 7, and a cavity is formed between the upper disc working disc 7 and the upper disc water cooling disc 5 2. A water inlet 3 and a water outlet 6 are provided on the upper water cooling plate 5, and the water inlet 3 and the water outlet 6 communicate with the cavity 2 respectively.

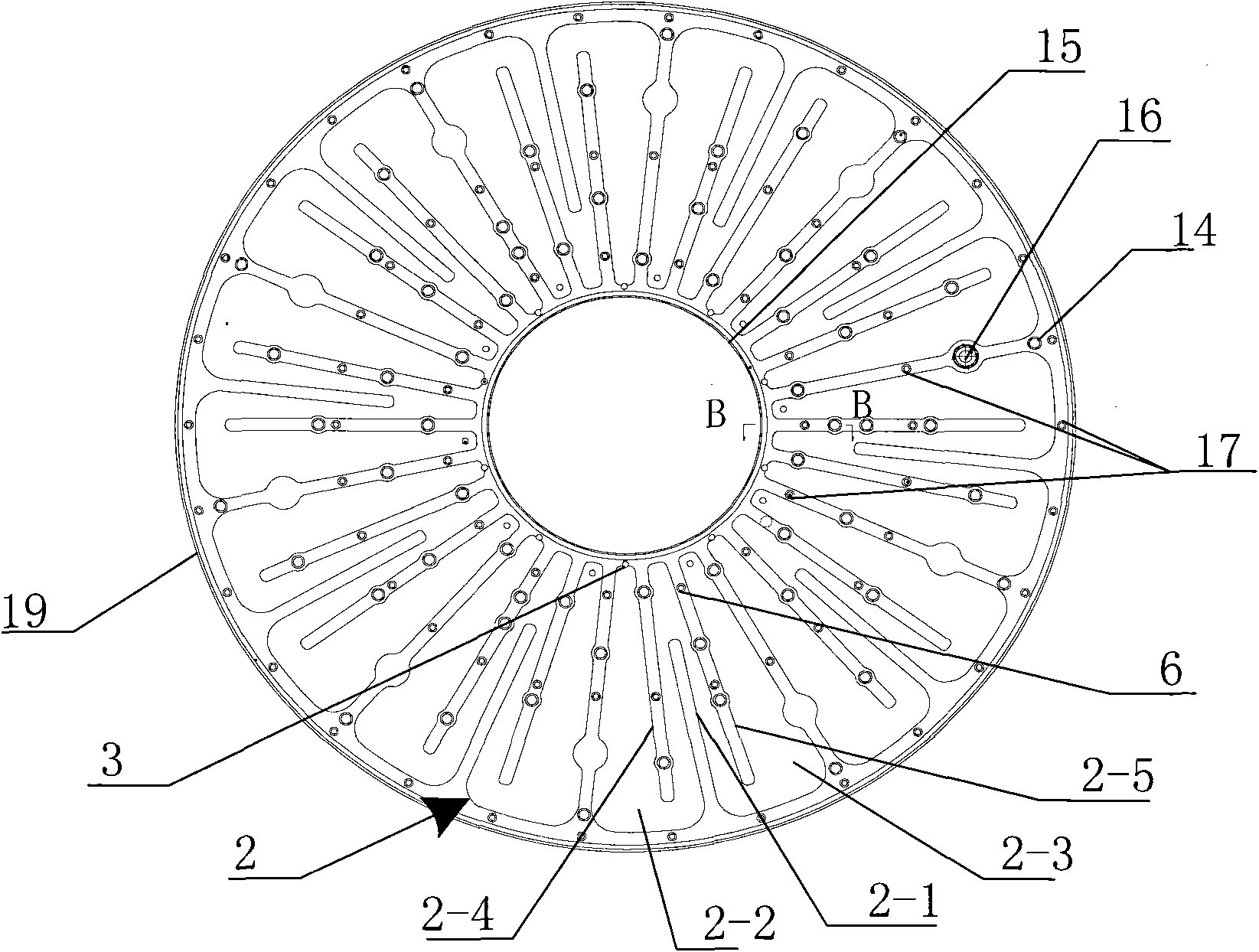

[0019] A cavity 2 is formed between the upper plate water cooling plate 5 and the upper plate working plate 7, and the cavity 2 is provided with several concave fan-shaped areas on the upper plate water cooling plate 5 to form several Fan-shaped cooling cavity. Each sunken fan-shaped area is divided into two interconnected sunken water inlet areas 2-2 and water outlet areas 2-3 by the protruding dividing rib 2-1. The water outlet 3 is provided with a water outlet 6 in the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com