Microwave sulfur lamp

A technology of sulfur lamps and microwaves, applied in the field of lighting lamps, can solve the problems of short life, mercury pollution of electrodes, high energy consumption, etc., and achieve the effects of long life, low energy consumption, and fast cold start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

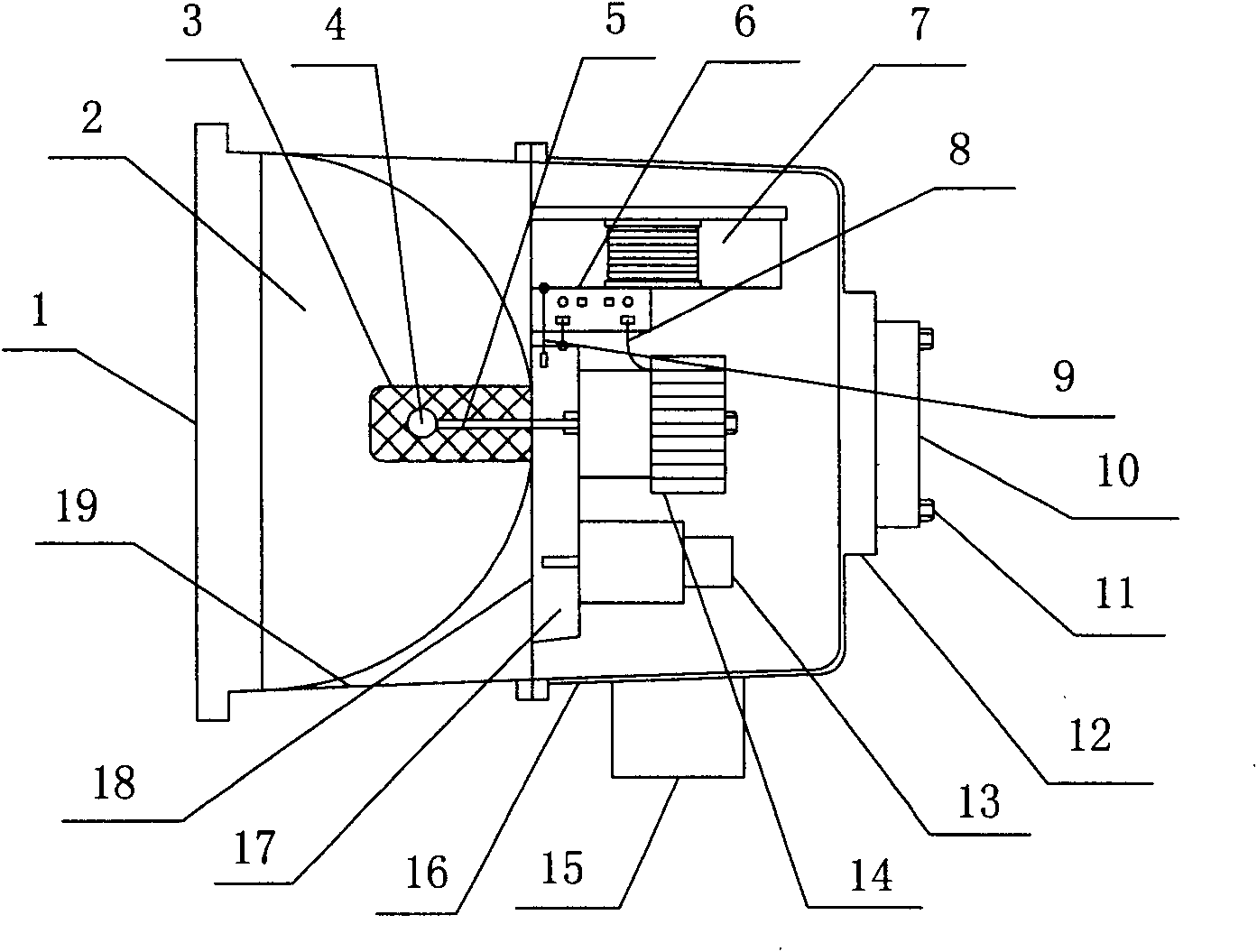

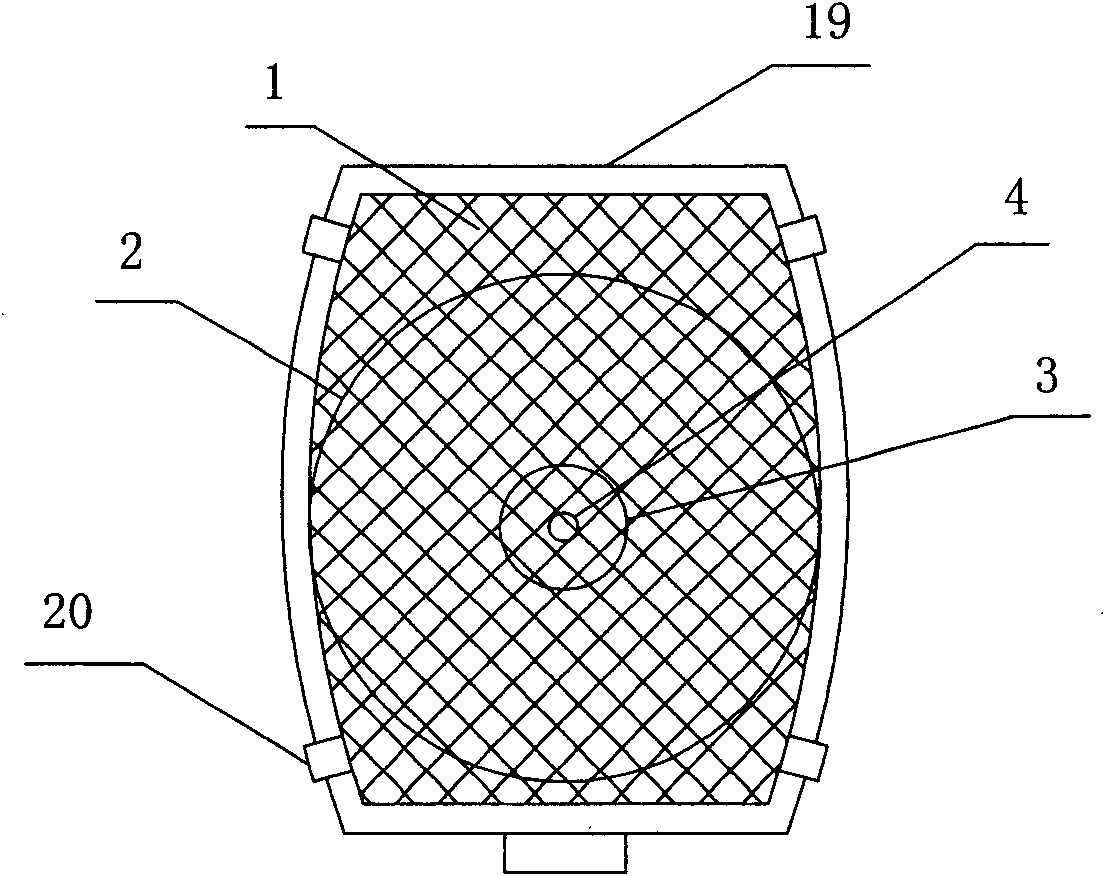

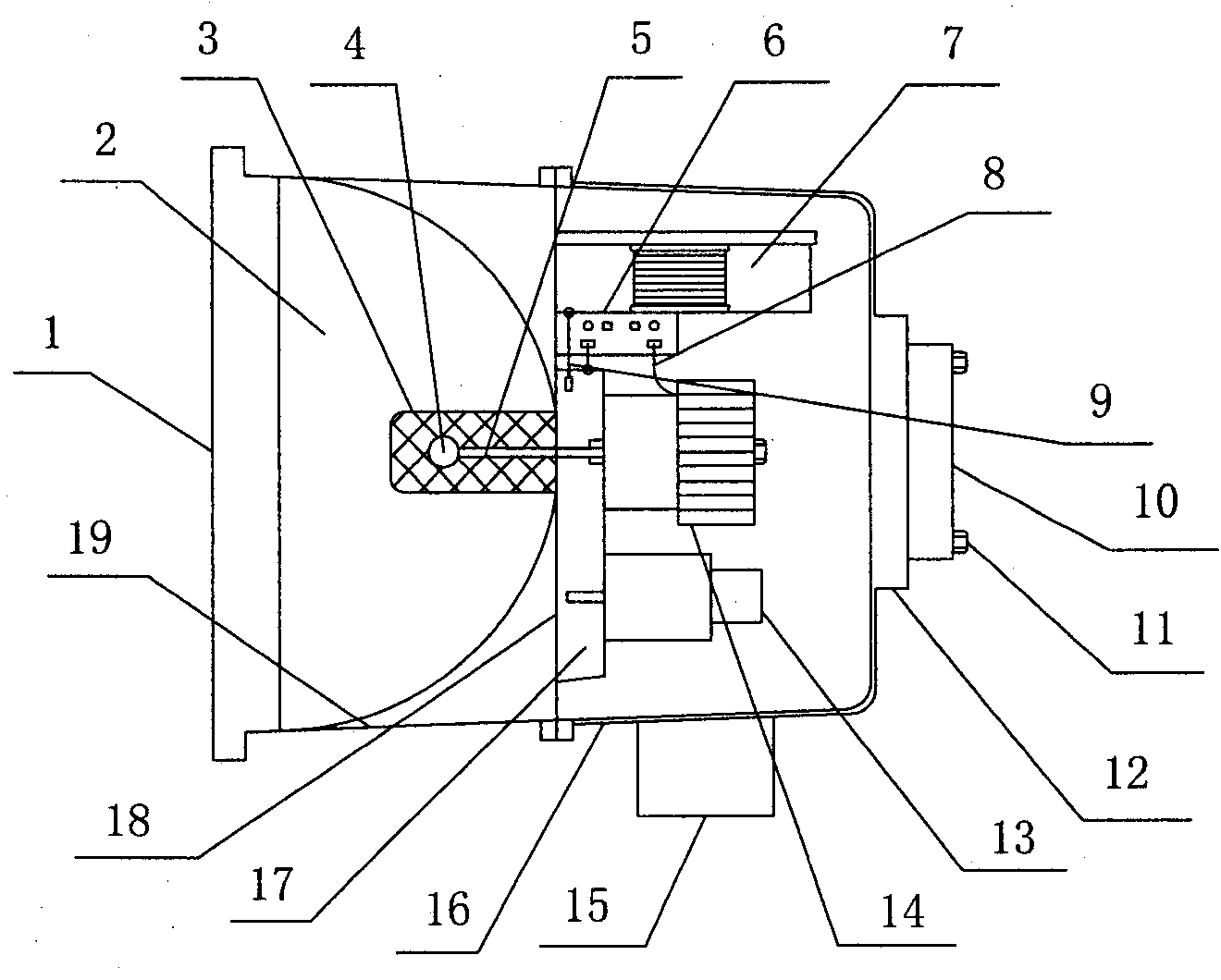

[0008] Figure 1-2 The lower side of the housing 16 shown in the figure is provided with a shield 19, and a fixed connecting plate 18 is arranged inside the housing. The upper end of the fixed connecting plate is equipped with an electronic frequency conversion board 7, and the lower side of the electronic frequency conversion board is equipped with a control board 6. , the middle part of the fixed connection plate is provided with a cooling fan 14, the middle part of the cooling fan is provided with a sulfur lamp bulb rod 5, and the bottom end of the sulfur lamp bulb rod is equipped with a sulfur lamp bulb 4. The control board is provided with power connection wires 8, 9, and the power connection wires are respectively connected on the electronic frequency conversion board and the motor of the cooling fan. The bottom side of the heat dissipation fan is provided with a resonant cavity 17, the bottom of the resonant cavity is provided with a shield 3, the sulfur lamp bulb 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com