Arrangement structure of subcritical circulating fluidized bed boiler

A technology of circulating fluidized bed and layout structure, used in steam boilers, steam generation, lighting and heating equipment, etc., can solve the problems of difficult layout of downcomers, large space in front of the furnace, etc. Large space and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

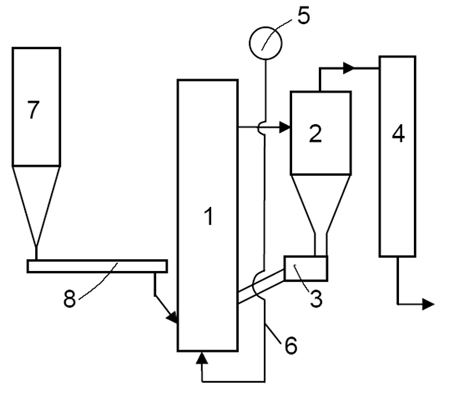

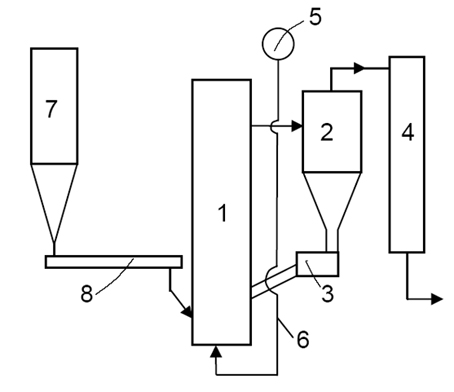

[0015] based on the following figure 2 The preferred embodiment of the present invention is described in detail:

[0016] Such as figure 2 As shown, it is an arrangement structure of a subcritical circulating fluidized bed boiler. The boiler includes a furnace 1, and is arranged in the space behind the furnace, and is sequentially connected to the return system 3 of the furnace 1, the cyclone separator 2, and the tail convection flue 4. It also includes the feeder 8 and the fuel bin 7 in front of the furnace, which are arranged in the space in front of the furnace and connected to the furnace 1 in sequence.

[0017] Described boiler also comprises steam drum 5 and the downcomer 6 that connects steam drum 5 and furnace 1, and described steam drum 5 and downcomer 6 are arranged between furnace 1 and cyclone separator 2, and steam drum downcomer 6 is along The space between the furnace 1 and the cyclone separator 2 is arranged downwards to supply water to the furnace.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com