Substrate cleaning machine and substrate cleaning method

A technology for cleaning machines and substrates, which is used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as increased product defect rate and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

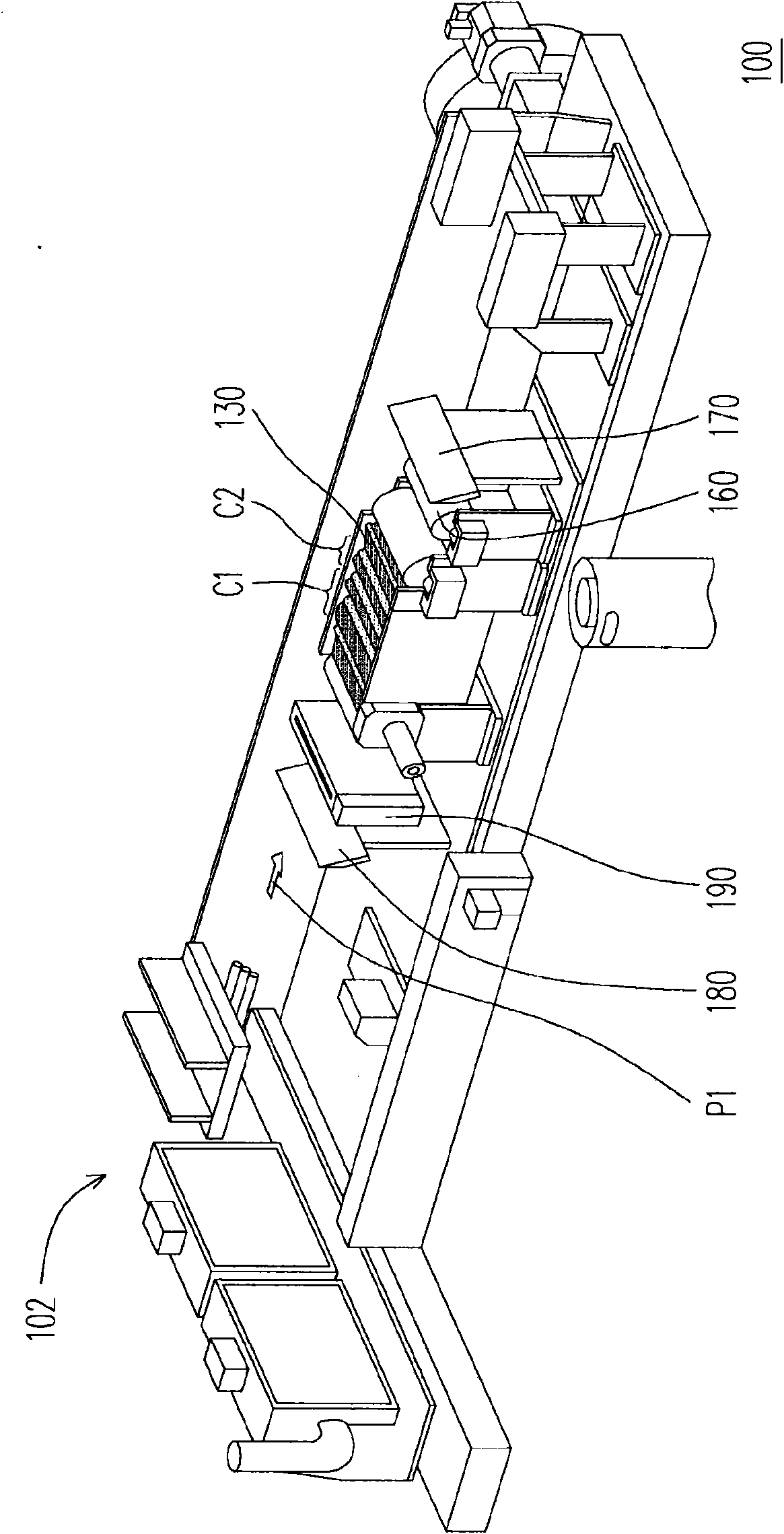

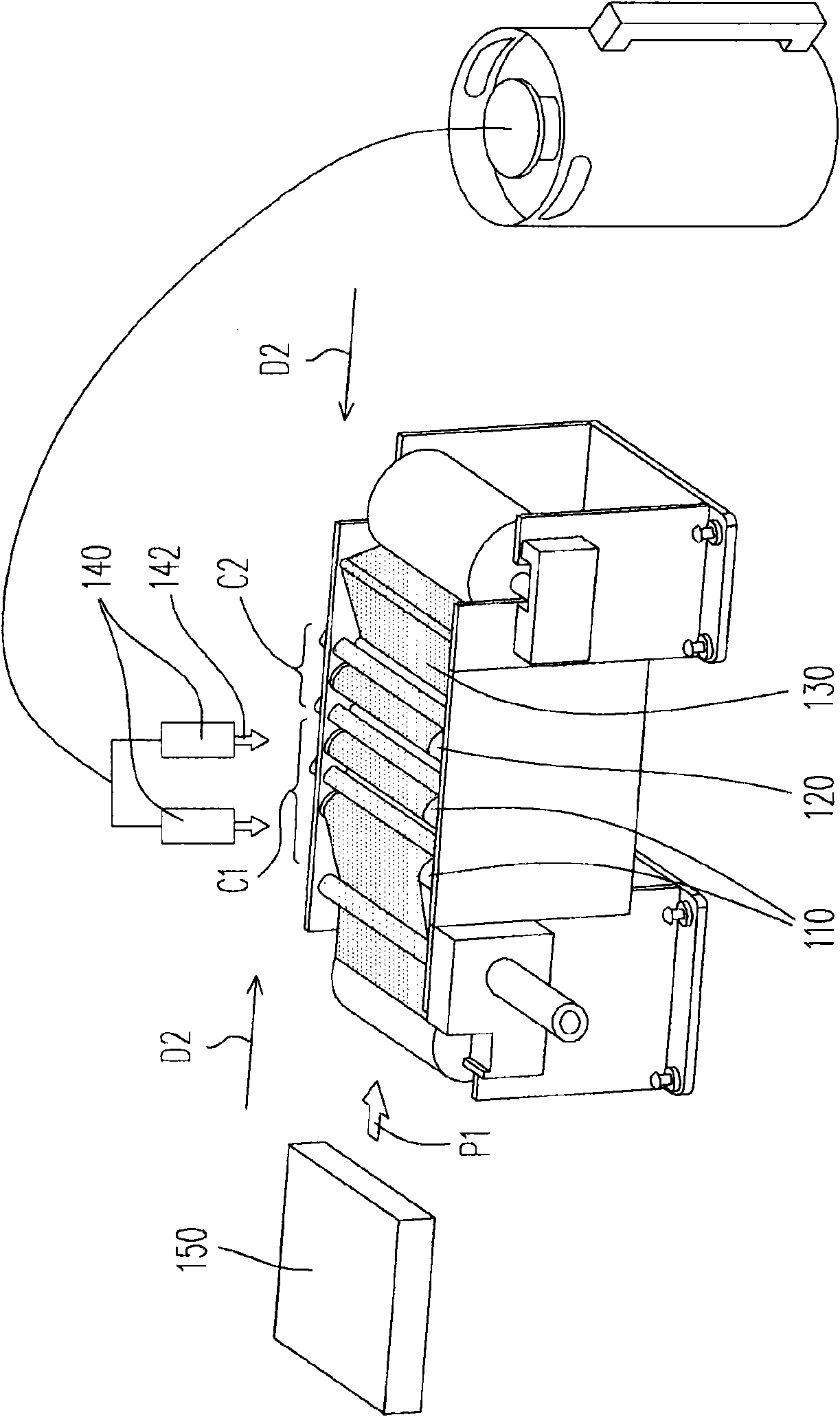

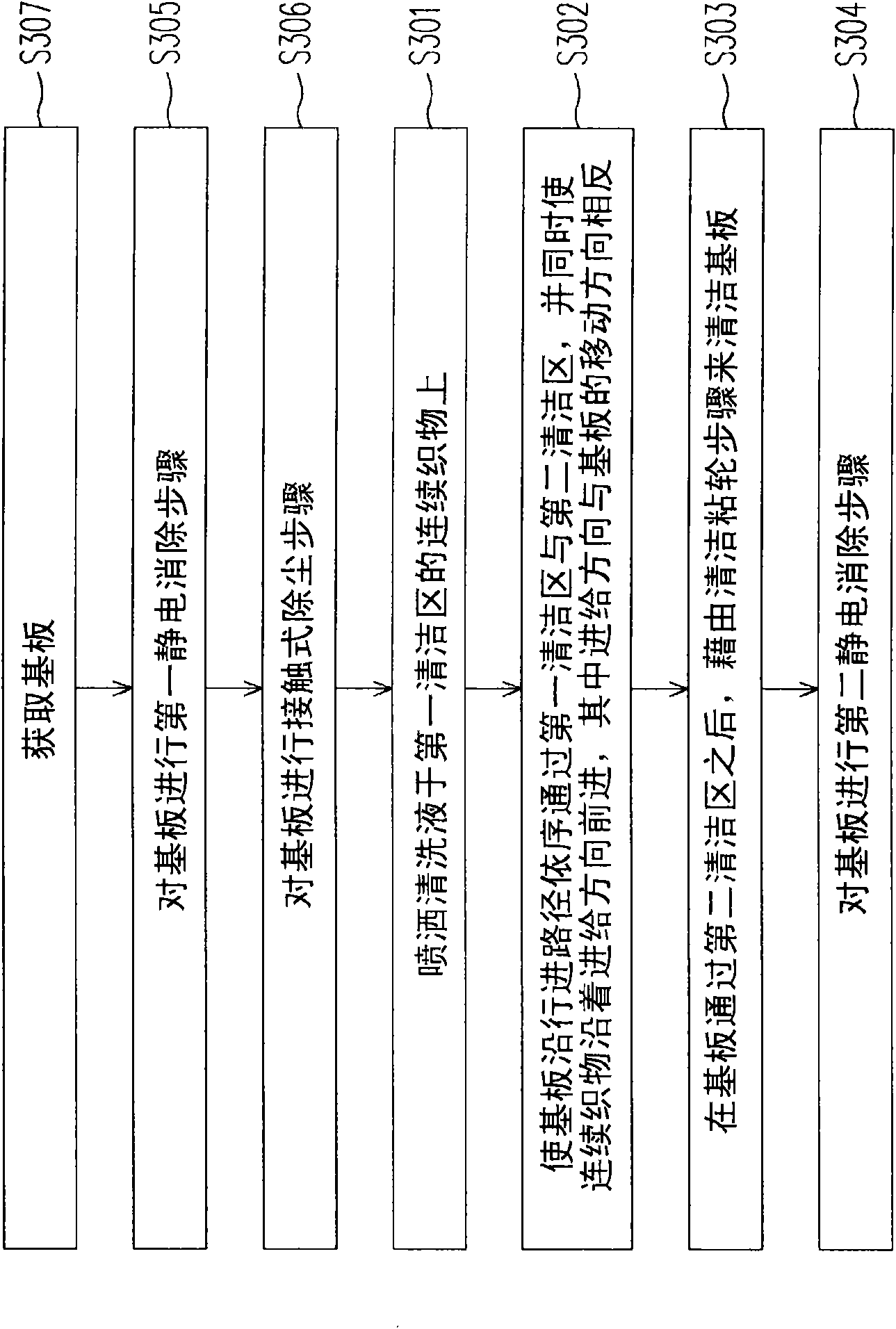

[0044] figure 1 is a schematic diagram of a substrate cleaning machine according to an embodiment of the present invention, figure 2 for figure 1 The local schematic diagram of the substrate cleaning machine, and image 3 for a suitable figure 1 A flow chart of the steps of the substrate cleaning method of the cleaning machine. Please also refer to figure 1 and figure 2 , the substrate cleaning machine 100 of this embodiment includes a first support 110 , a second support 120 , a continuous fabric 130 and a nozzle 140 . The first supporting member 110 and the second supporting member 120 are respectively disposed on the traveling path P1 of the substrate 150 , and the substrate 150 is adapted to pass over the first supporting member 110 and the second supporting member 120 sequentially along the traveling path P1 . In this embodiment, the first supporting member 110 and the second supporting member 120 are illustrated as rollers, but not limited thereto. In addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com