Arm for spectacles

A technology of glasses legs and composite materials, applied in the directions of glasses/protective glasses, glasses/goggles, optics, etc., can solve the problems of fragmentation, sharp edges, lack of adhesion, etc., and achieve good resilience and good mechanical properties. , the effect of reducing the risk of shedding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

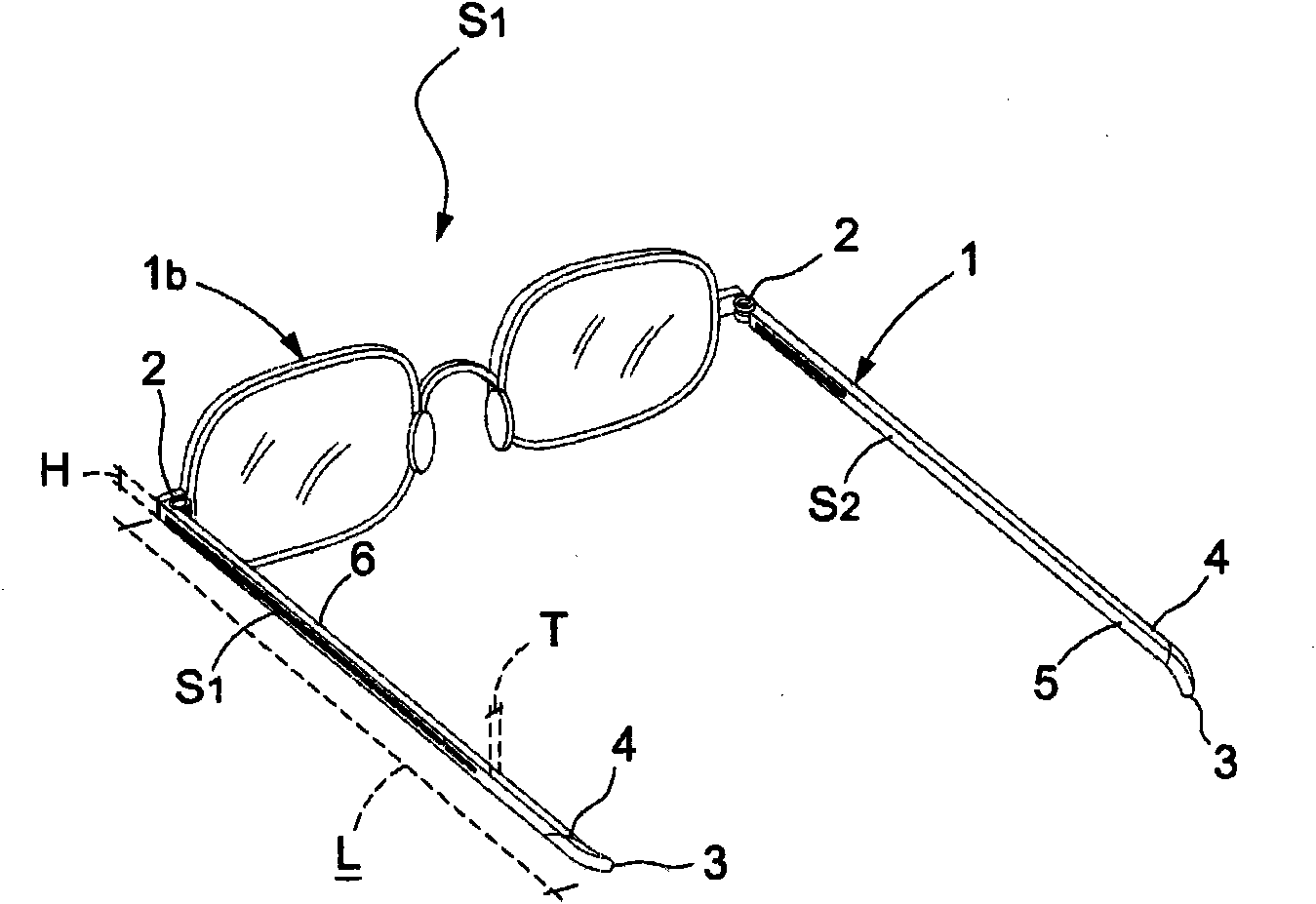

[0049]With reference to the figures, the reference number 1 designates the entire temple, which is suitable for the production and is only schematically indicated in figure 1 A normal pair of glasses 1a. The glasses 1a may be vision correcting glasses, sunglasses, sports glasses, ski glasses, or the like.

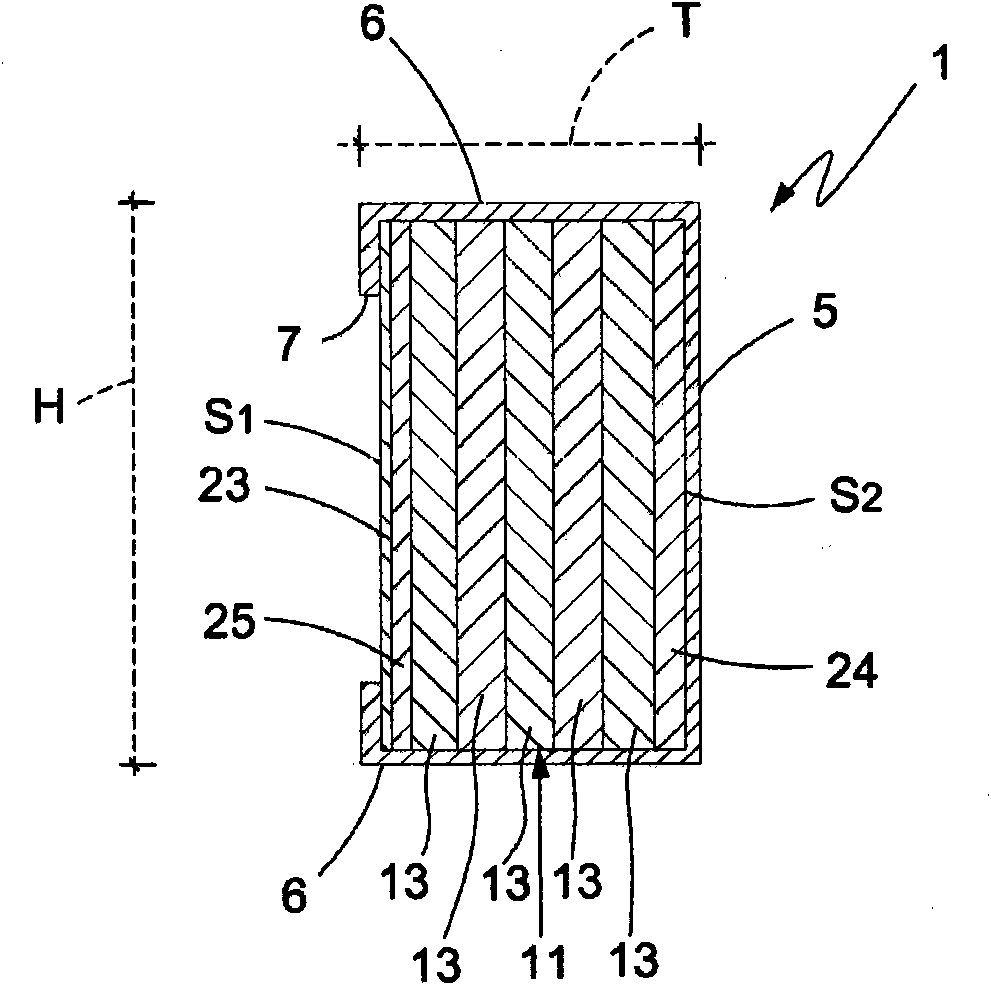

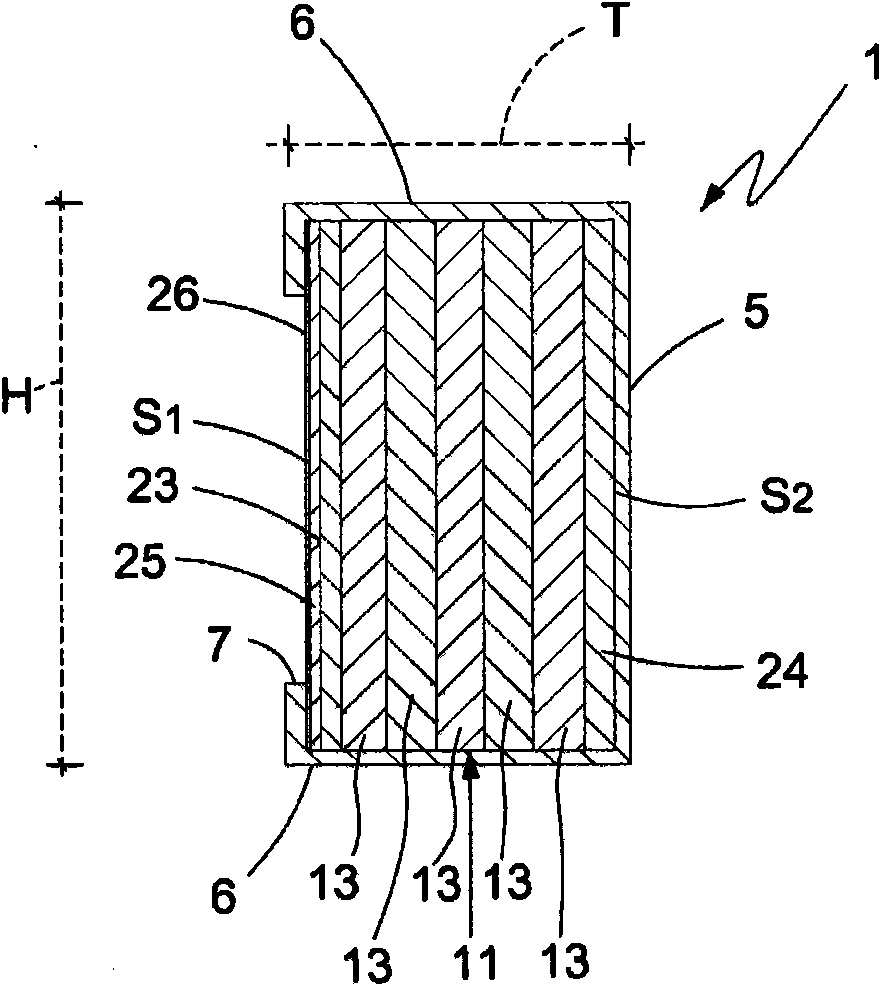

[0050] Preferably, the temple 1 is plate-shaped, defining opposite main surfaces S1 and S2 thereon. The first surface S1 is defined as that surface which is visible when the glasses are worn.

[0051] The temple 1 extends mainly in the longitudinal direction, has a longitudinal length L, a height H perpendicular to the length L and parallel to the wearer's head when the wearer puts on the glasses, and a thickness T.

[0052] In order to manufacture different types of glasses, the value of the length L of the glasses legs can be changed appropriately, for example, the legs of glasses for children should have a shorter length L, and the legs of glasses for adults should hav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com