Fomesafen and clethodim weedicide for soybean fields

A technology of fomesafen and clethodim, applied in the field of herbicides in soybean fields, can solve problems such as affecting the use effect of mixtures, and achieve the effects of reducing the burden on farmers, improving stability and solving weed damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

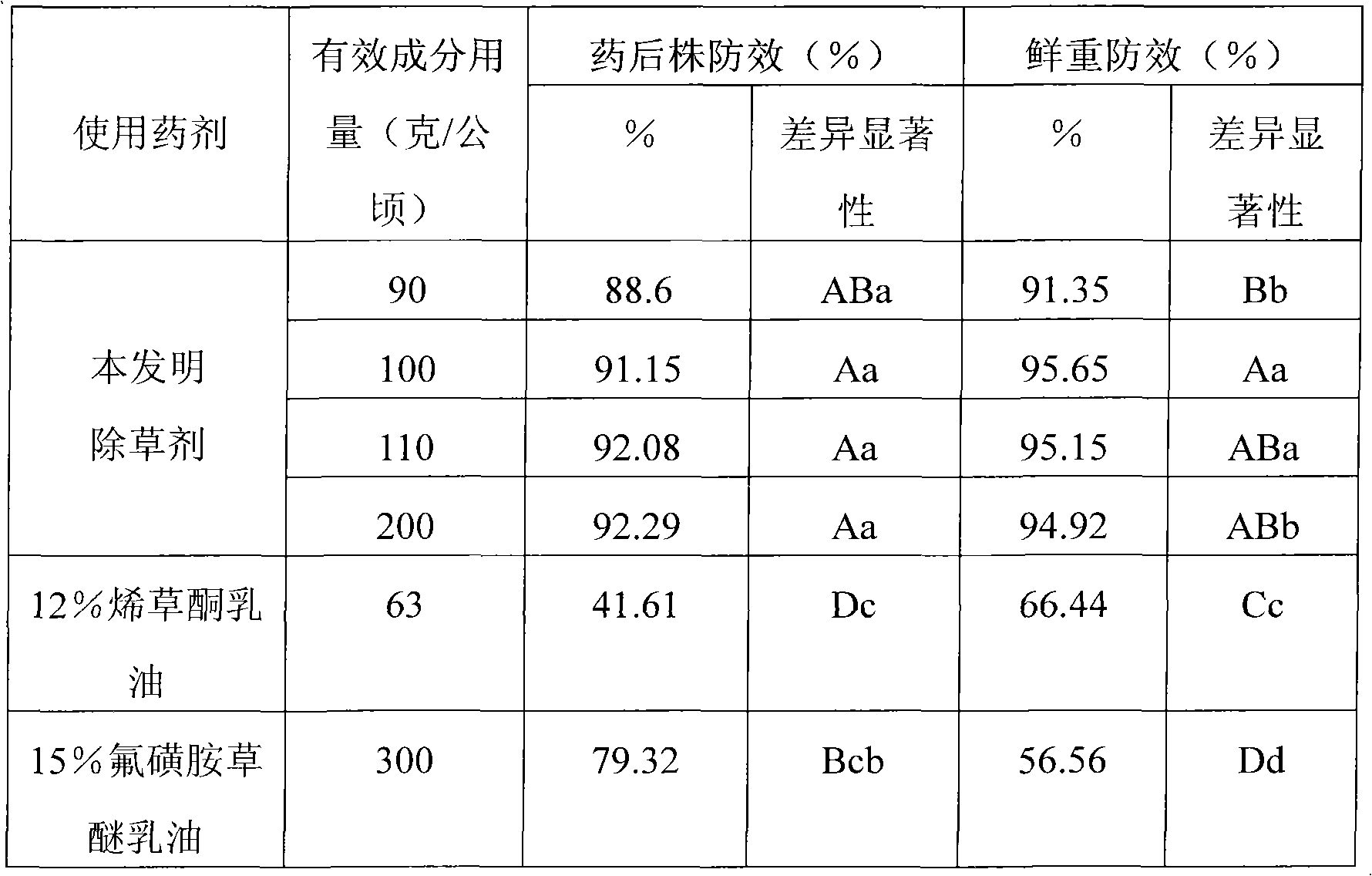

Examples

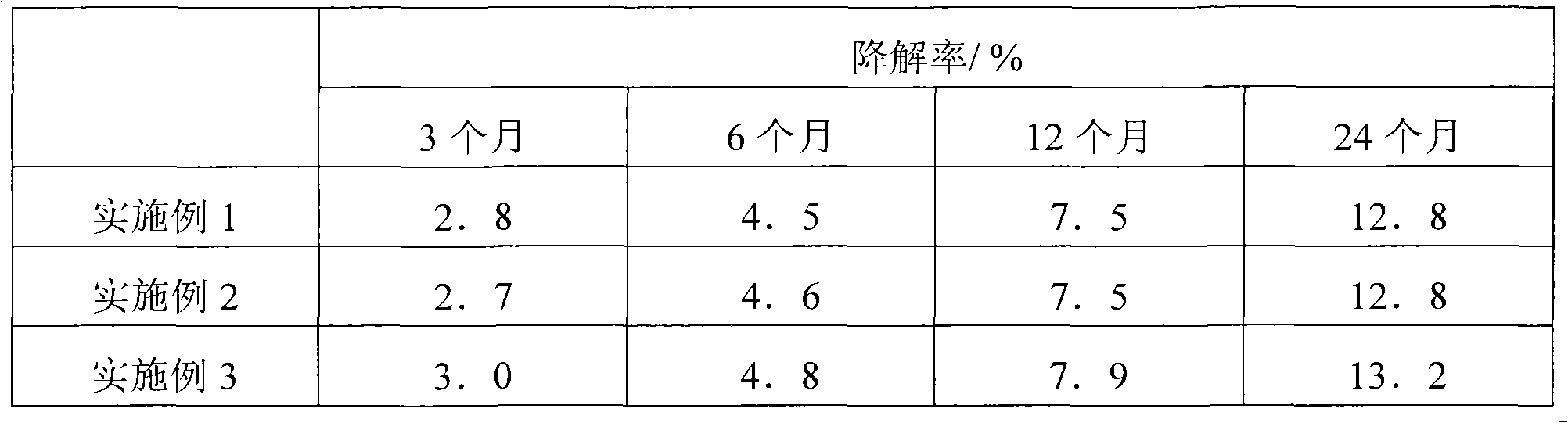

Embodiment 1

[0026] Preparation of 100kg fomesafen and clethodim soybean field herbicide

[0027] Fomesafen 12kg,

[0028] Clethodim 13kg,

[0029] Dimethylformamide 17kg,

[0030] Stabilizer N-methyldiethanolamine 8kg,

[0031] Tween 80 7.5kg,

[0032] The remainder is water;

[0033] The preparation steps are as follows:

[0034] (1) 13kg of fomesafen and 17kg of dimethylformamide were mixed and stirred to completely dissolve fomesafen to obtain mixture A;

[0035] (2) mixing material A with 13kg clethodim and 8kgN-methyldiethanolamine, stirring, and mixing uniformly to obtain compound B;

[0036] (3) Mix 42.5kg water and 7.5kg emulsifier, stir evenly, add mixture B, stir well, and make water emulsion.

[0037] After the production is completed, the product content is tested, and the product is packaged after passing the test.

Embodiment 2

[0039] Preparation of 100kg fomesafen and clethodim soybean field herbicide

[0040] Fomesafen 15kg,

[0041] Clethodim 15kg,

[0042] Dimethylformamide 20kg,

[0043] Stabilizer N-methyldiethanolamine 10kg,

[0044] Tween 80 10kg,

[0045] The remainder is water;

[0046] The preparation steps are as follows:

[0047] (1) 15kg of fomesafen and 20kg of dimethylformamide were mixed, stirred, and fomesafen was completely dissolved to obtain mixture A;

[0048] (2) mixing material A with 15kg clethodim and 10kgN-methyldiethanolamine, stirring evenly to obtain mixing material B;

[0049] (3) Mix 30kg of water and 10kg of emulsifier, stir evenly, add mixture B, stir well, and make water emulsion.

[0050] After the production is completed, the product content is tested, and the product is packaged after passing the test.

Embodiment 3

[0052] Preparation of 100kg fomesafen and clethodim soybean field herbicide

[0053] Fomesafen 10kg,

[0054] Clethodim 10kg,

[0055] Dimethylformamide 15kg,

[0056] Stabilizer N-methyldiethanolamine 5kg,

[0057] Tween 80 5kg,

[0058] The remainder is water;

[0059] The preparation steps are as follows:

[0060] (1) Mix 10kg of fomesafen and 15kg of dimethylformamide, stir, and completely dissolve fomesafen to obtain mixture A;

[0061] (2) mixing material A with 10kg clethodim and 5kg N-methyldiethanolamine, stirring evenly to obtain mixing material B;

[0062] (3) Mix 55kg water and 5kg emulsifier, stir evenly, pour mixture B into, stir well, and make water emulsion.

[0063] After the production is completed, the product content is tested, and the product is packaged after passing the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com