Tunnel type continuous microwave solid-liquid countercurrent extraction system

A tunnel-type, microwave technology, applied in the direction of solid solvent extraction, chemical/physical/physicochemical processes of energy application, etc., can solve the problems of difficult discharge of solid materials, difficult to achieve countercurrent, high processing precision, short time to achieve, and continuous The effect of modernization and industrialization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the scope shown in the embodiments.

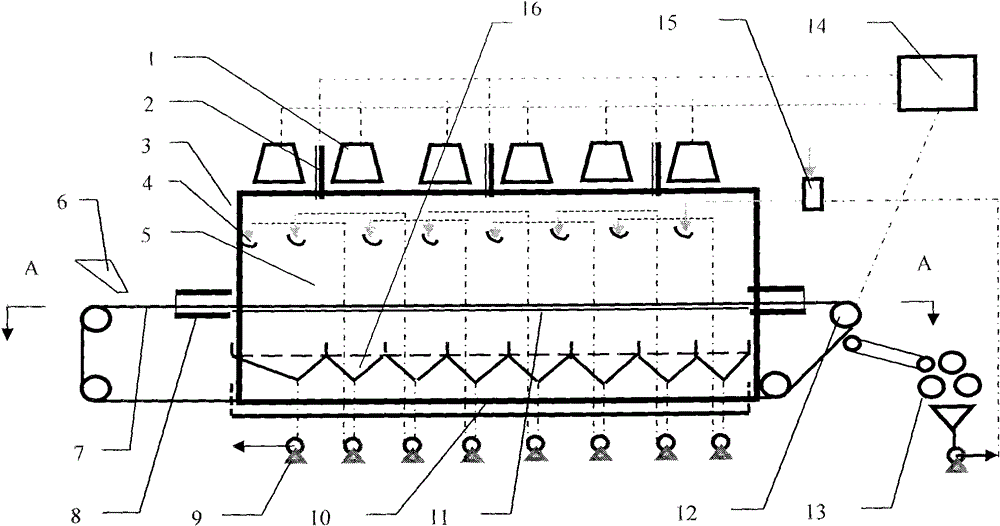

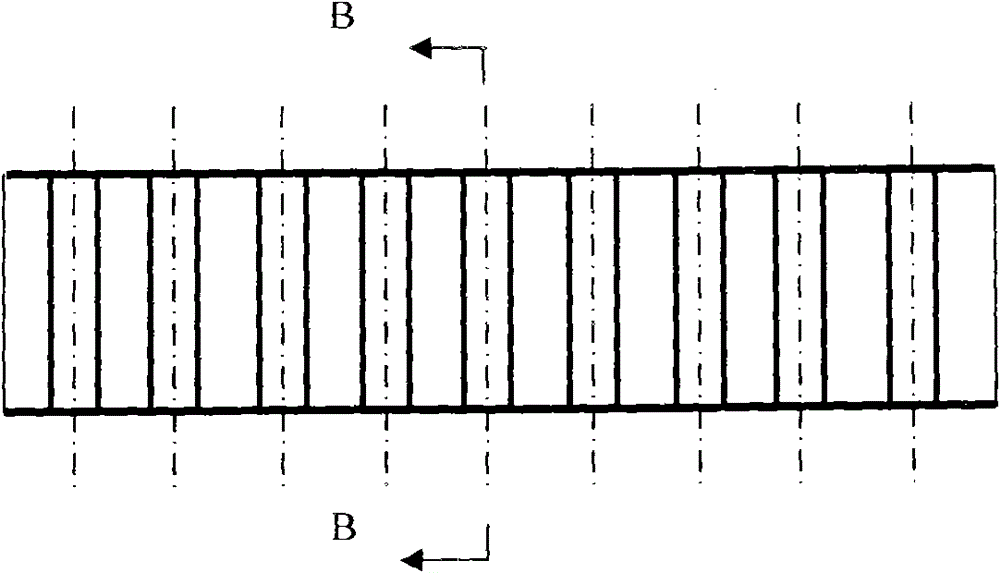

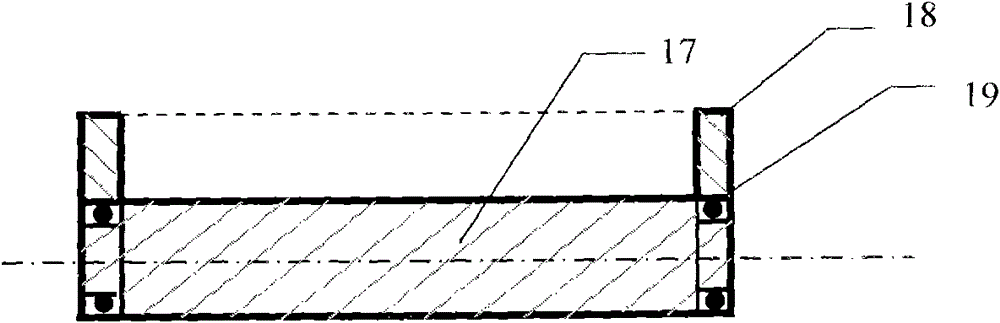

[0024] Such as figure 1 , 2 , 3, a tunnel-type continuous microwave solid-liquid countercurrent extraction system, comprising an extraction chamber 5, a microwave magnetron 1, a conveyor belt 7, a conveyor belt support 11, a drive wheel 12, a high-level overflow tank 4, a pump 9, a high-level Groove 15 and receiving groove 16; Extraction cavity 5 is a hollow cavity, is surrounded by microwave cavity outer wall 3 and forms, is preferably a cuboid cavity; Extraction cavity 5 upper ends are evenly distributed a plurality of microwave magnetrons 1, in microwave heating extraction cavity 5 The top of the magnetron 1 is distributed with a microwave feeding port of the magnetron 1; the front and rear ends of the extracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com