Truck-frame side beam and crossbeam connecting joint totally-butted structure and assembly-welding process method

A technology of connecting joints and process methods, which is applied to bogies, manufacturing tools, welding equipment, etc., can solve problems that affect the carrying capacity and operating speed of bogies, large stress concentration coefficients, and reduce fatigue life of structures, so as to achieve continuous structural shape , Small stress concentration, small welding residual stress and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

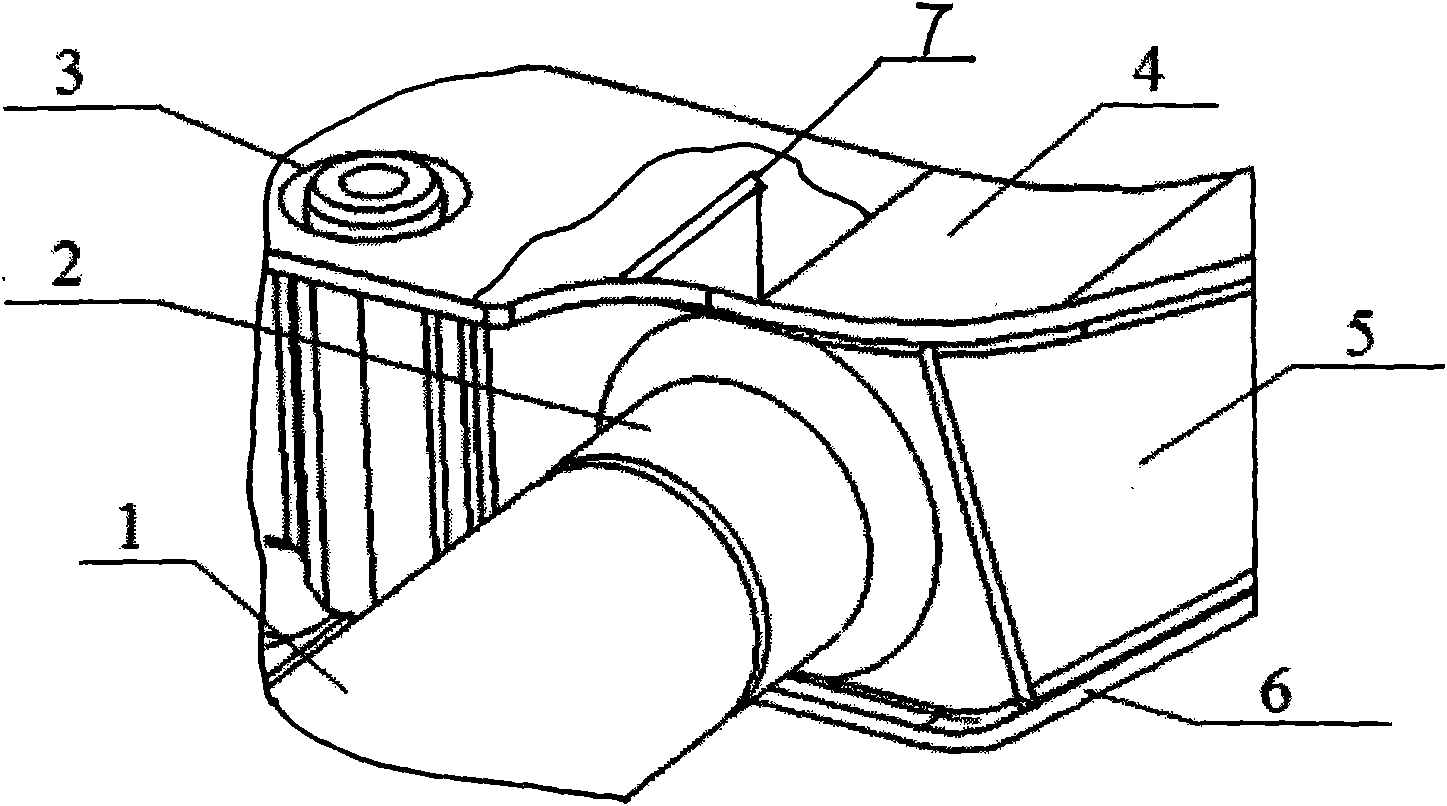

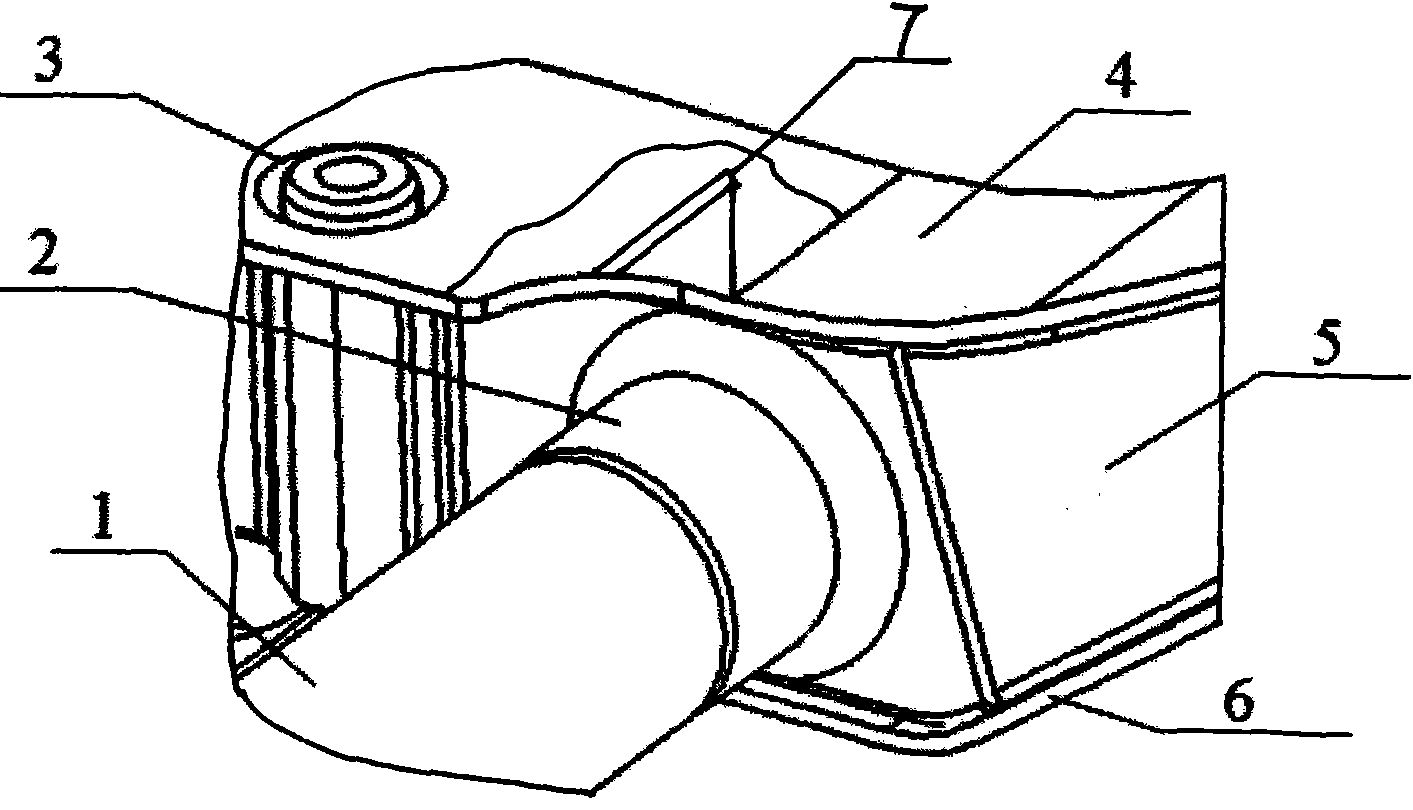

[0010] Referring to Fig. 1, the side beam and the cross beam 1 are fully butt connected through the connecting seat 2, and the side beam connection end forms a plate-plate butt joint structure with the side beam inner vertical plate 5 and the guide column 3, and the cross beam connection end and the cross beam form a tube - Pipe butt joint structure, 4 is the upper cover plate, 6 is the lower cover plate, and 7 is the side beam reinforced partition.

[0011] Bogie frame assembly welding process with full butt joint structure of side beams: When the side beams are semi-finished products (side beam grooves without upper cover plates), they are combined with beams to complete the overall frame assembly, which is one of the most prominent features of the new frame assembly welding process First, this process breaks through the traditional process of combining side beams and beams with finished products and then combining frames. Using this process can ensure automatic MAG welding o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com