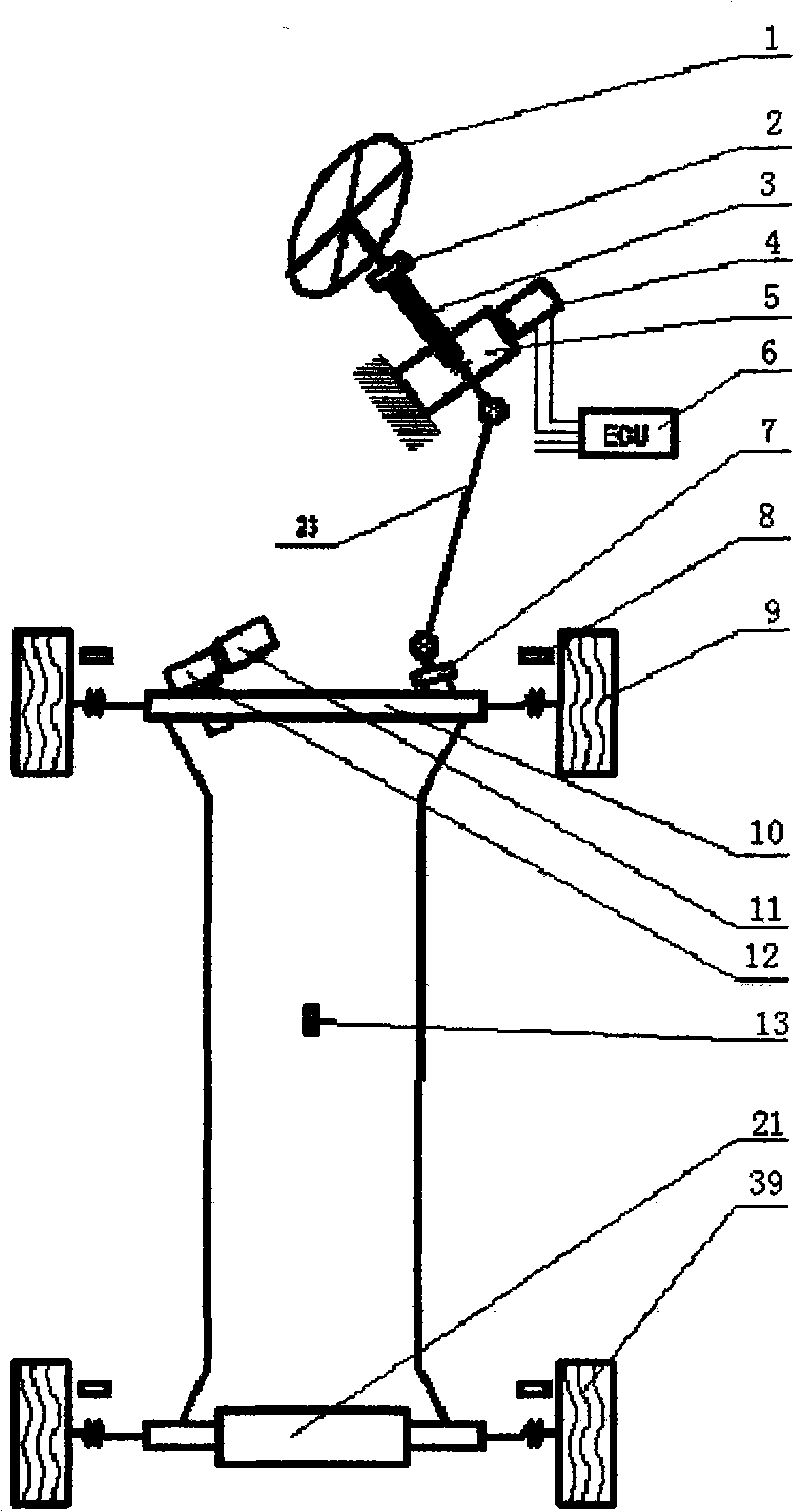

Integral active electric power-assisted steering mechanical structure

A technology of electric power steering and mechanical structure, applied in the field of steering and steering, can solve the problems of affecting the driving stability, reducing the steering stroke, and the steering flexibility of the car has not been greatly improved, so as to ensure the road response, reduce the turning radius, Comfortable and responsive to the road

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

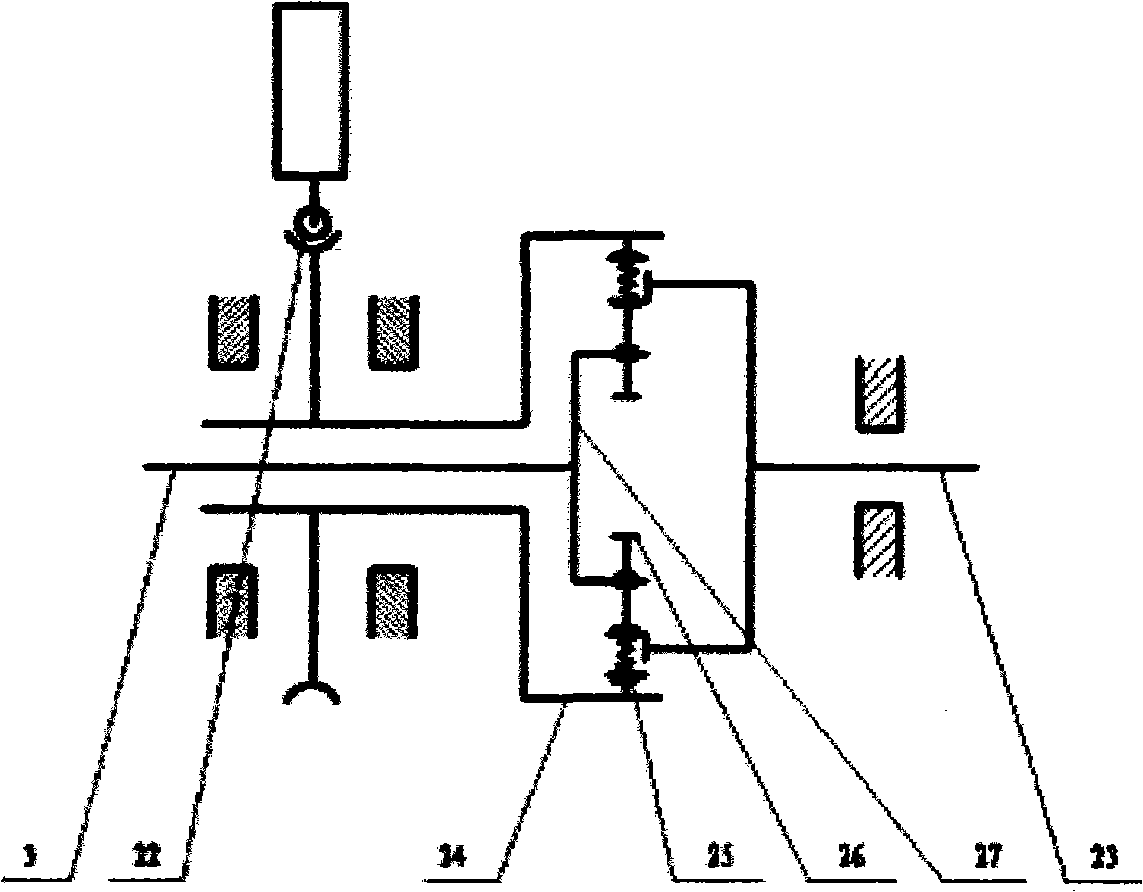

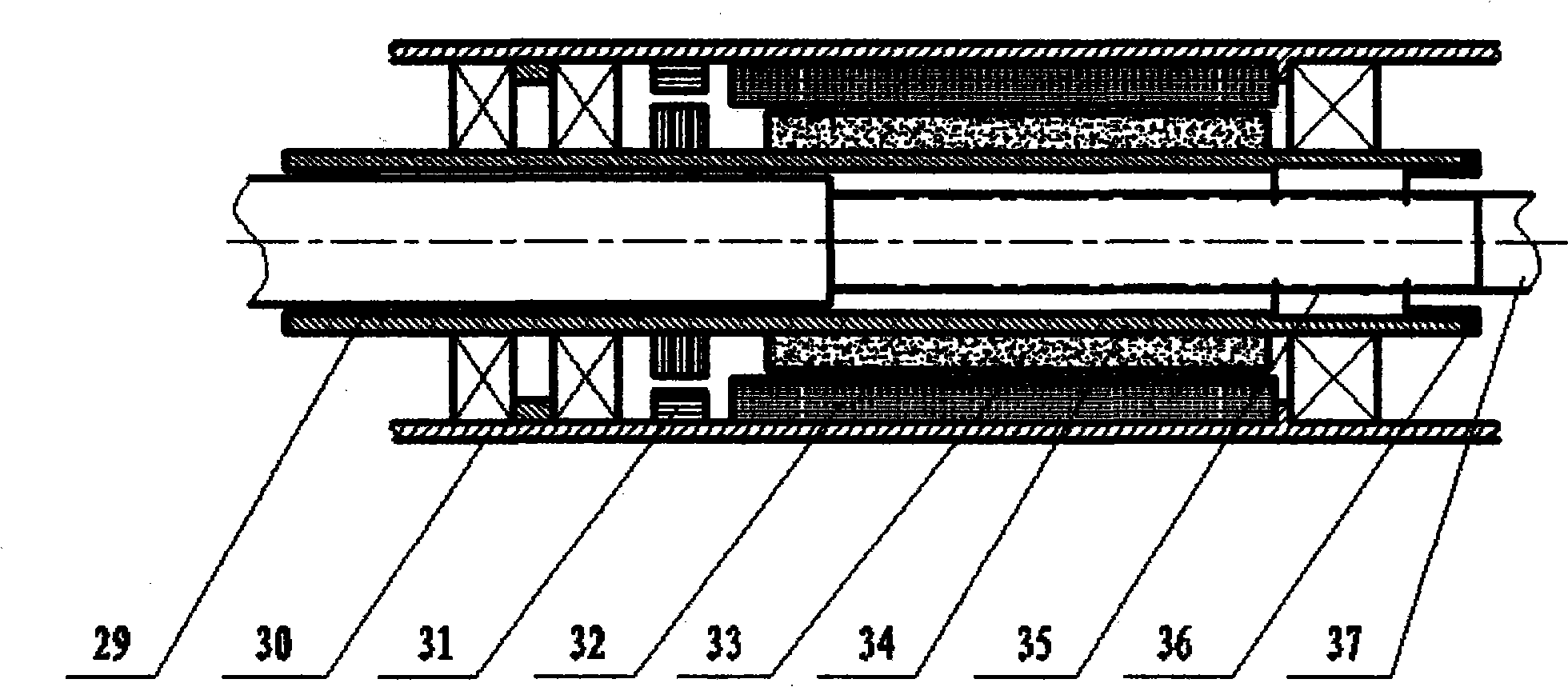

Method used

Image

Examples

Embodiment 1

[0036] In embodiment one: the car is in the low-speed driving state:

[0037] The steering control module 14 in the controller 6 drives the front-wheel steering system and the rear-wheel steering system 21 to steer in reverse phase. Since the steering gear ratio module 15 provides a small steering transmission ratio at low speeds, the steering torque increases. The steering control module 6 must apply steering torque compensation to the power assist motor 11, so as to obtain excellent handling performance—lightweight, direct steering, and can reduce the steering radius to make the vehicle more flexible and agile.

[0038] In the second embodiment: the car is in the state of changing lanes at high speed, and performs cornering operation:

[0039] The controller 6 steering control module 14 front wheel steering system, the steering angle transmission ratio module 15 provides a large steering transmission ratio and slow steering, and then the controller 6 steering control module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com