Traveling crane position tracking device based on radio frequency identification

A driving position and tracking device technology, applied in the field of driving position tracking, can solve the problems of heavy installation workload and difficulty in obtaining high positioning accuracy, and achieve the effects of reducing installation workload, improving guiding significance, and eliminating positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

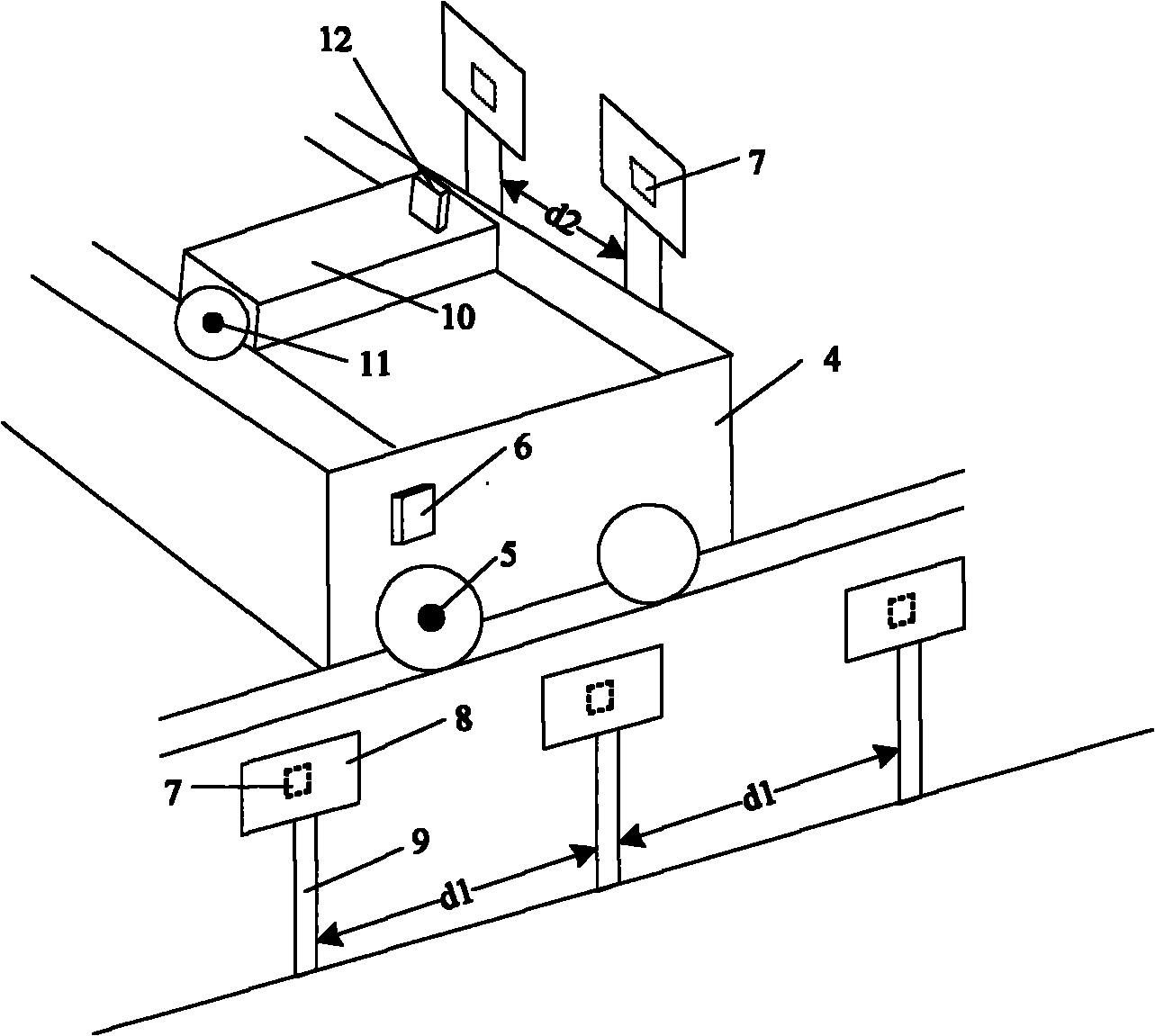

[0024] The application of a driving position tracking device of the present invention in the steel coil storage area of a steel plant will be taken as an example to further describe the present invention in detail below.

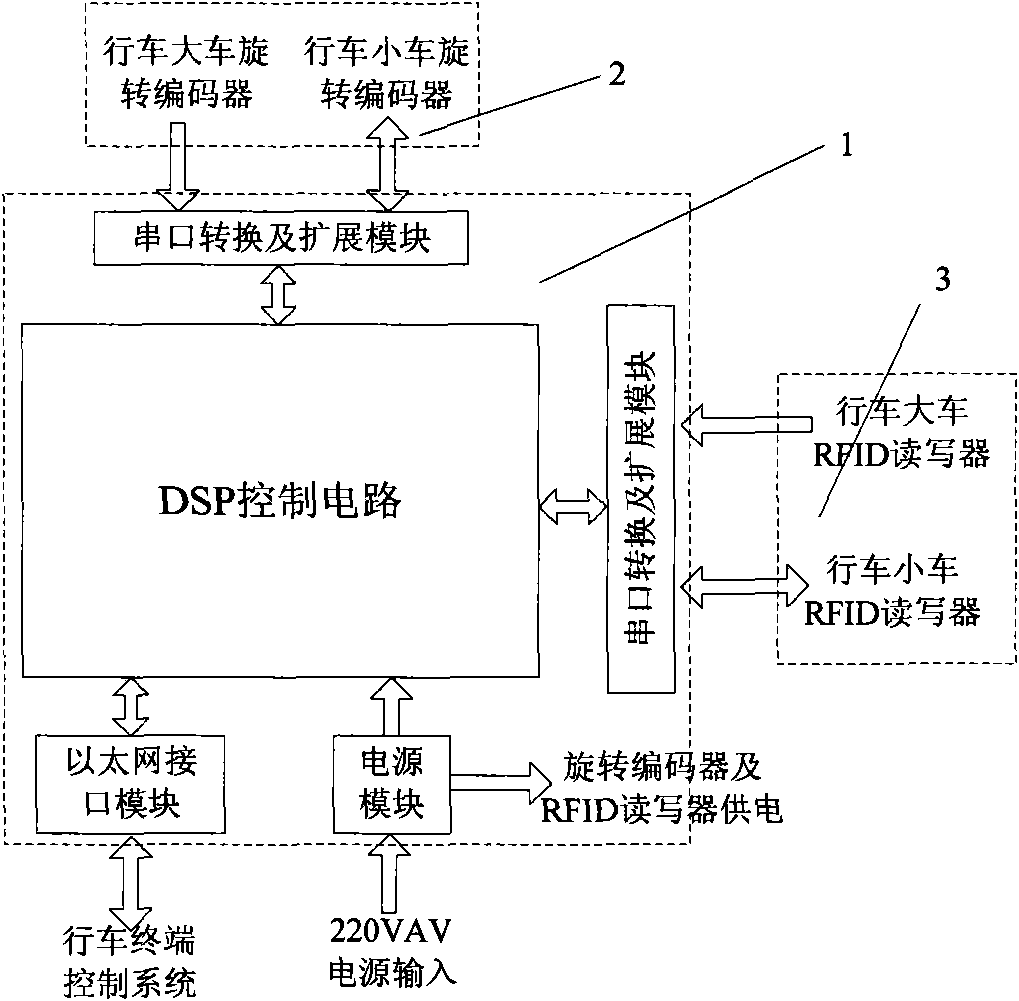

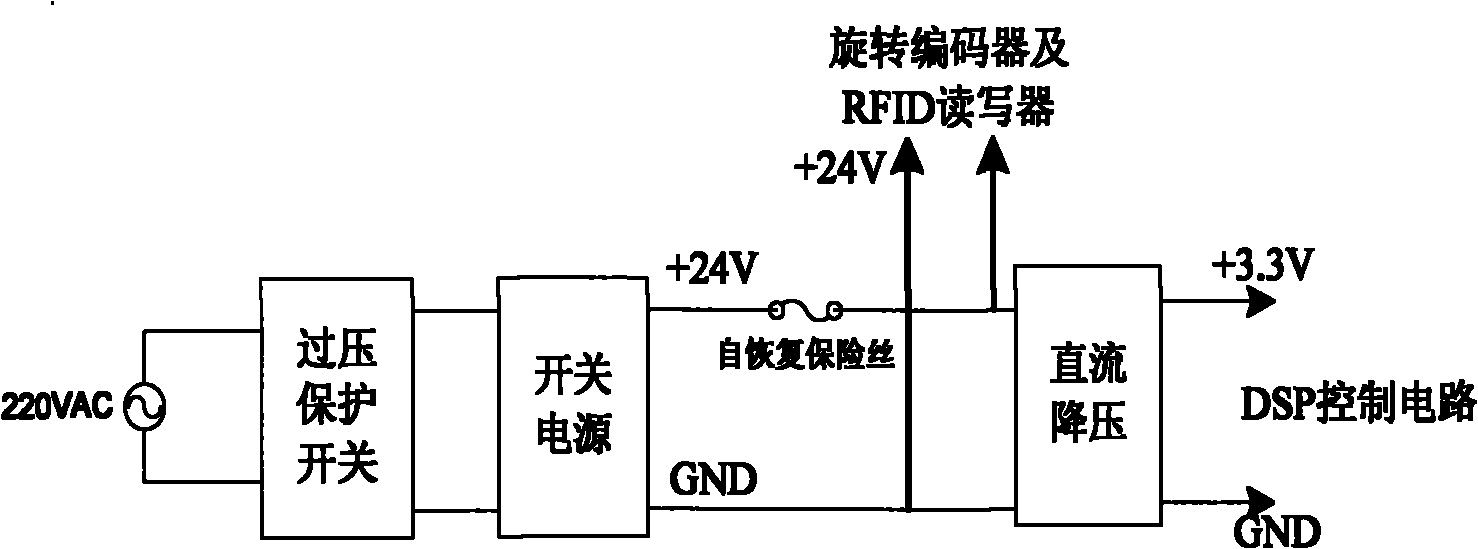

[0025] Such as figure 1 , figure 2 As shown, the device consists of three parts: main controller 1, position detection device 2, and position calibration device 3. The main controller 1 includes a DSP control circuit, a power supply module, a serial port conversion and expansion module, and an Ethernet interface module. The position detection device 2 includes a rotary encoder and a rotary encoder communication cable. The position calibration device 3 includes an RFID cart reader, an RFID trolley reader, an RFID electronic tag, and a tag fixing bracket.

[0026] 1. Main controller part

[0027] The main controller part is placed in the driving cab, and its function is to collect the driving displacement information of the rotary encoder 5 of the drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com