Cast asphalt composition and preparation method thereof

An asphalt composition, pouring technology, applied in building structures, building components, building insulation materials, etc., can solve the problems of low temperature sensing performance, uncertain construction effect of modified asphalt, and no experimental examples of asphalt mixtures are proposed. , to achieve the effect of improving universality and strong construction operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

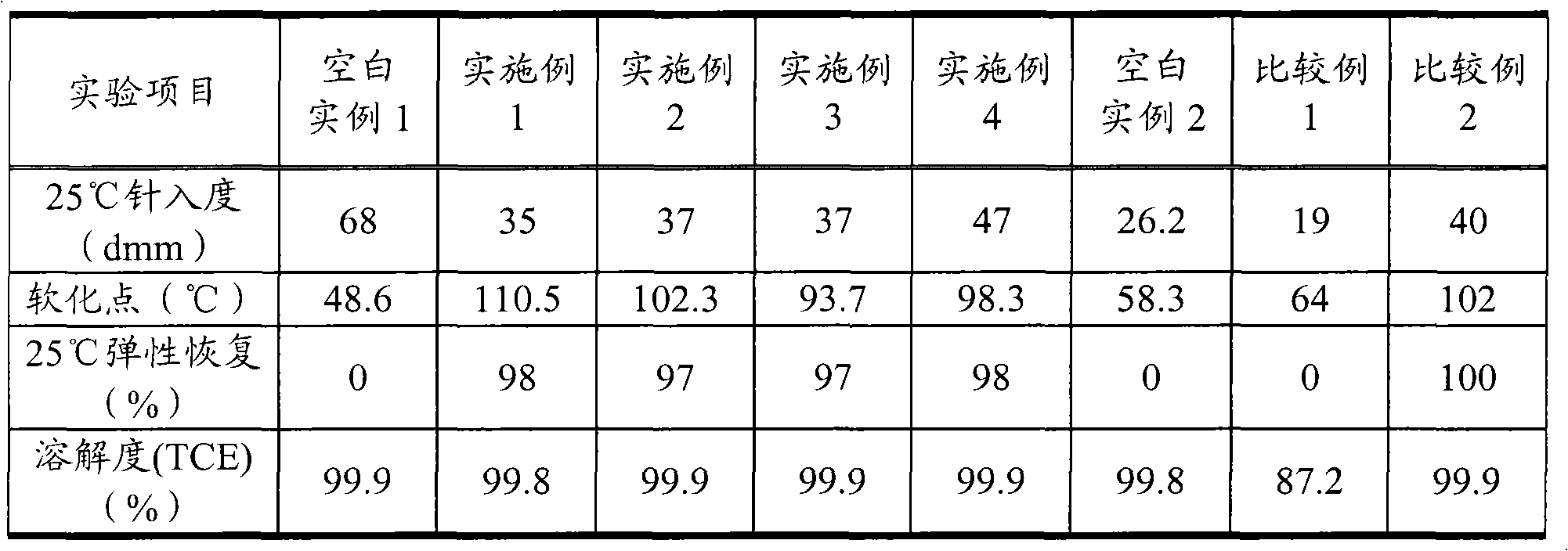

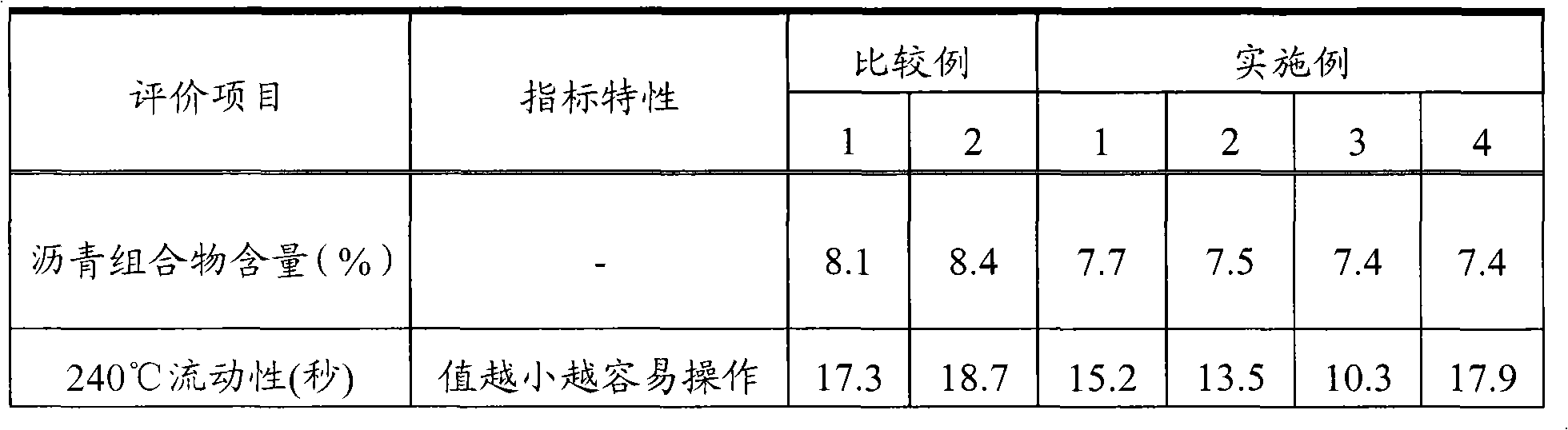

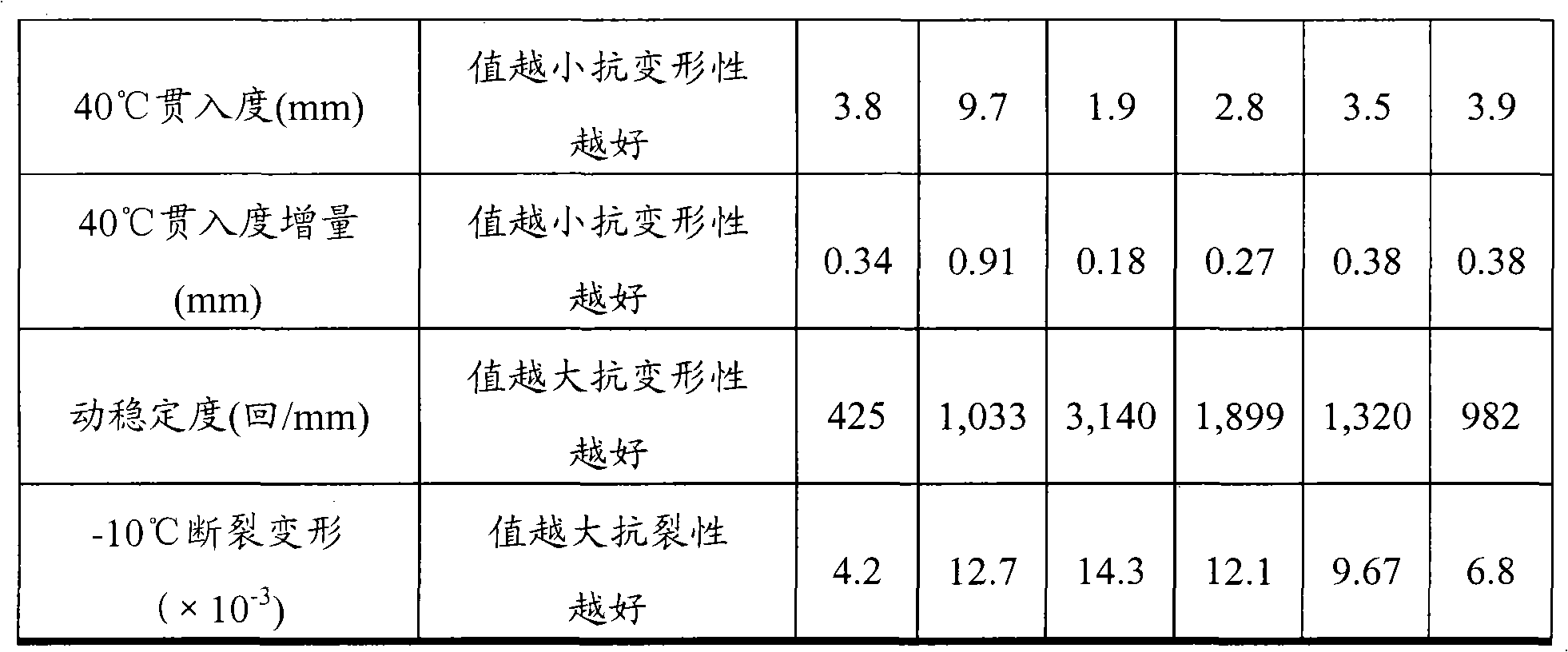

Embodiment 1

[0048] 83.2 parts of general-purpose petroleum-based asphalt (base asphalt) with a penetration of 68dmm at 25°C, 5.3 parts of SBS (30% styrene content, and 120,000 number average molecular weight), 0.5 parts of concentrated phosphoric acid with a concentration of 85%, 2.5 parts of saturated hydrocarbon process oil, 8.3 parts of natural asphalt with a penetration of 2dmm or less at 25°C, mixed and stirred for 4 hours at 190°C, then added 0.1 part of monomeric sulfur, stirred and reacted for 3 hours to obtain the product.

Embodiment 2

[0050] 81.6 parts of general-purpose petroleum asphalt (base asphalt) with a penetration of 68dmm at 25°C, 6.9 parts of SBS (30% styrene content, and 120,000 number average molecular weight), 0.3 parts of concentrated phosphoric acid with a concentration of 85%, 5.3 parts of saturated hydrocarbon process oil, 5.7 parts of natural asphalt with a penetration of 2dmm or less at 25°C, mixed and stirred for 4 hours at 190°C, then added 0.2 parts of monomeric sulfur, stirred and reacted for 3 hours to obtain the product.

Embodiment 3

[0052] 83 parts of general petroleum asphalt (base asphalt) with a penetration of 68dmm at 25°C, 7 parts of SBS (30% styrene content, 120,000 number average molecular weight), 0.1 part of concentrated phosphoric acid with a concentration of 85%, 7.1 parts of saturated hydrocarbon process oil, 2.5 parts of natural asphalt with a penetration of 2dmm or less at 25°C, mixed and stirred for 4 hours at 190°C, then added 0.3 parts of monomeric sulfur, stirred and reacted for 3 hours to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com