Tripod plug cage for river closure of flood-resisting buster and watercourse

A tripod and river channel technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as difficult positioning, difficult pile driving, and difficult transportation and transportation, so as to achieve easy manufacturing and installation, convenient storage and transportation, and reduce foundation clearing effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific structure of the tripod blocking cage for flood control and river closure of the present invention will be described in detail below with reference to the drawings and specific embodiments:

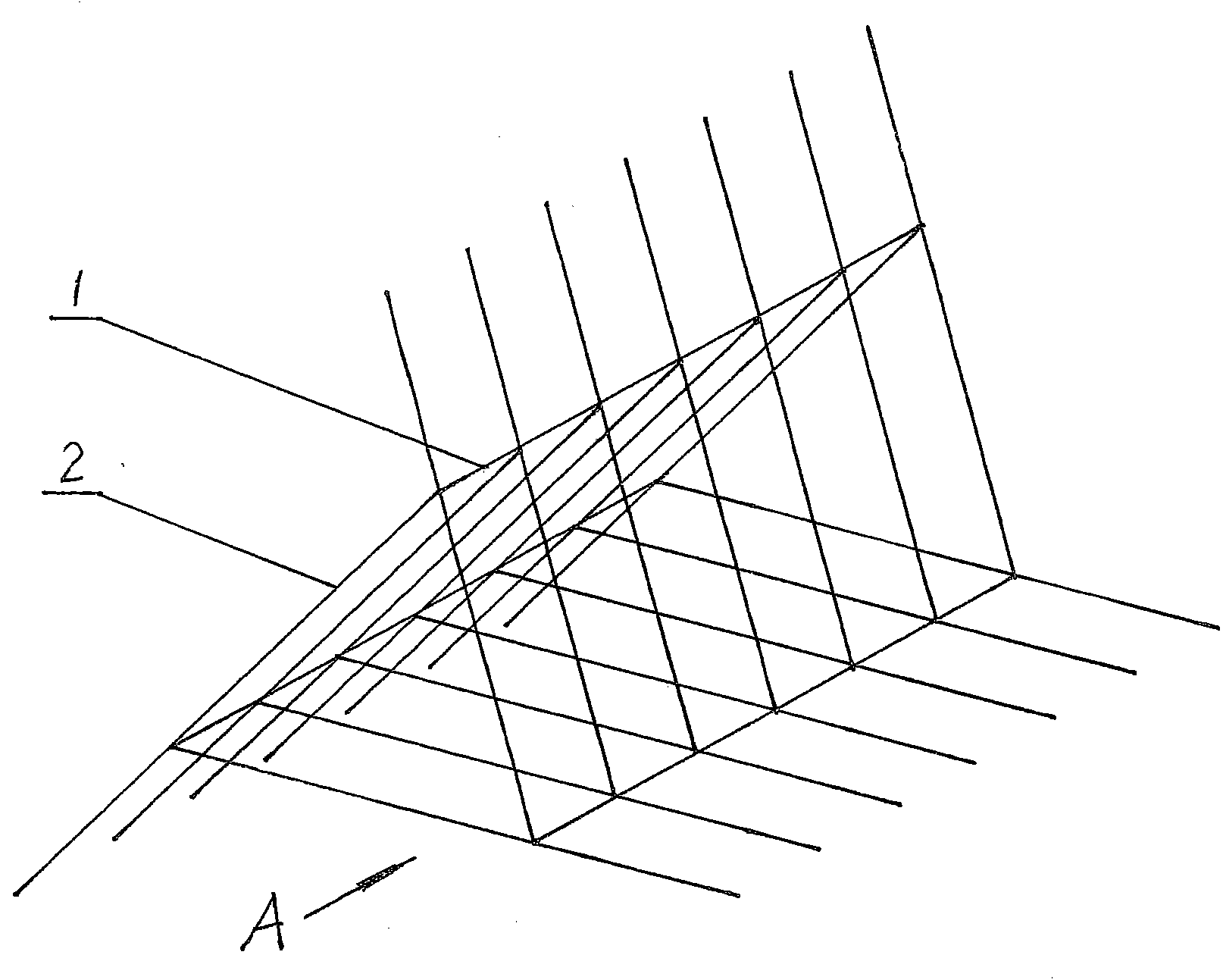

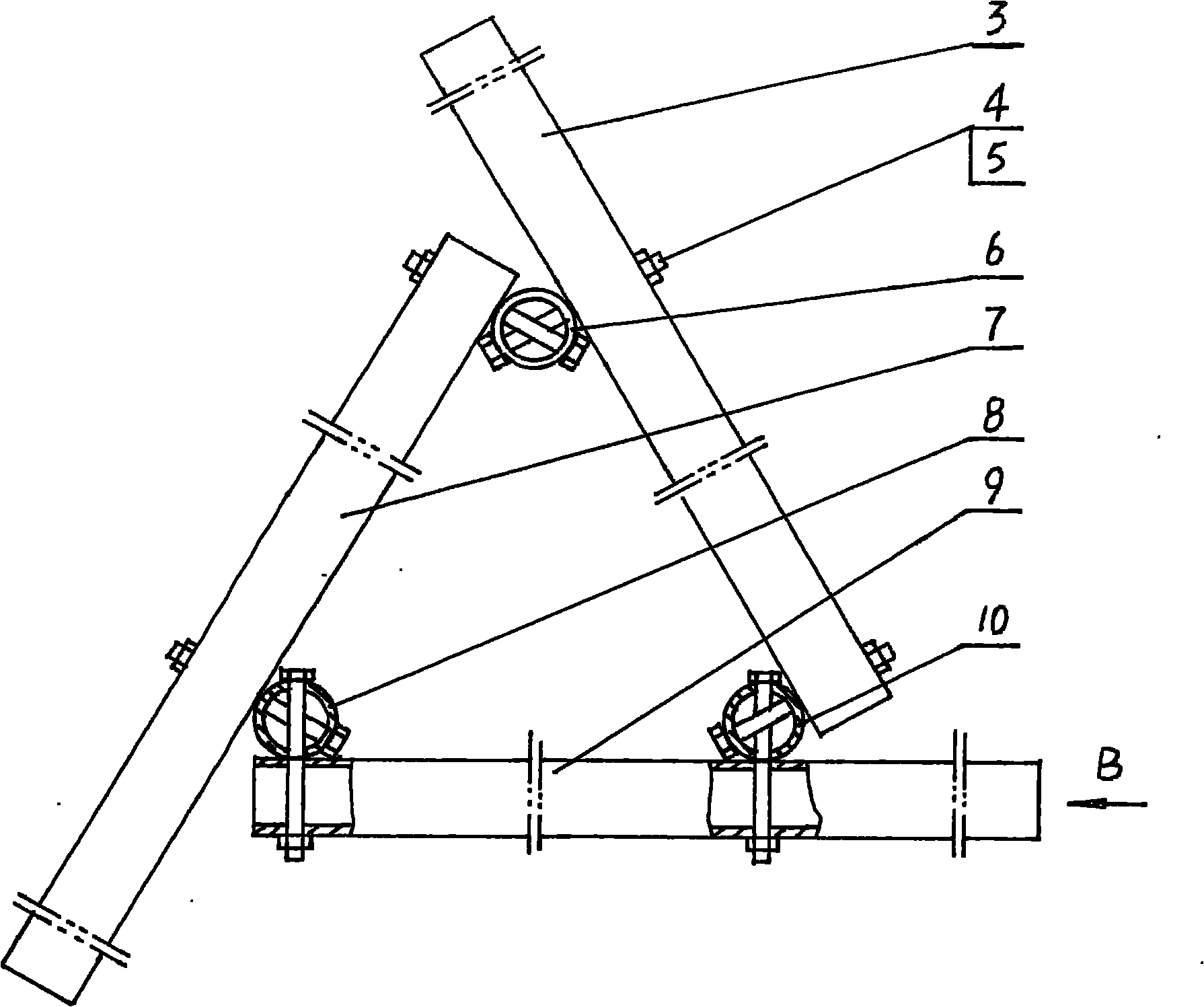

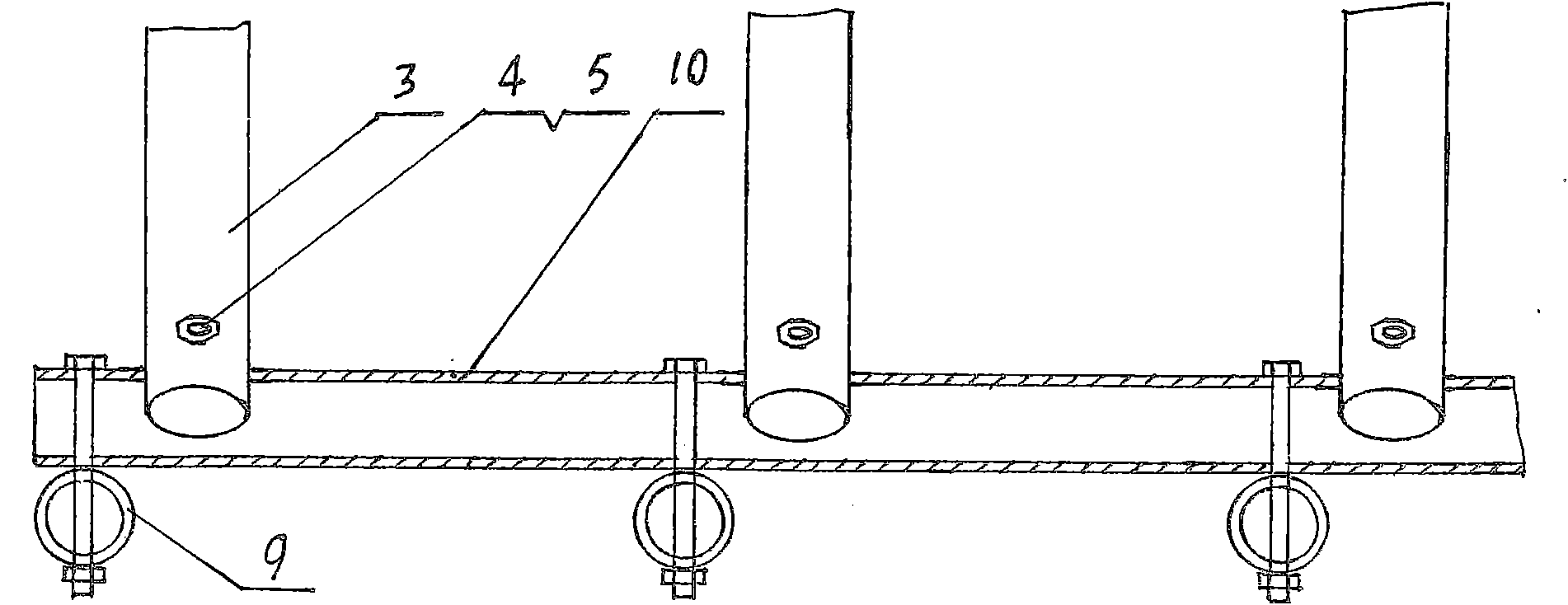

[0035] See Figure 1 to Figure 7 , The picture shows a tripod blocking cage for flood resistance and river closure. It is composed of 10 tripods connected with each other by a crossbar 1, and the tripod is composed of three vertical rods 2 connected to the crossbar. The crossbar 1 is made of steel pipe with an outer diameter of 57mm, a wall thickness of 3.5mm, and a length of 3m. The crossbar 1 is provided with 10 sets of pin holes. The diameter of the pin holes is 12mm, including the first pin hole 11 and the second pin hole 12. The distance between the first pin hole 11 and the second pin hole 12 is 60mm, the circumferential angle between the first pin hole 11 and the second pin hole 12 is 60°, and the first pin hole 11 in the first set of pin holes is The end is 30mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com