High efficiency torsion resistant drill rod joint with good sealing performance

A technology of sealing performance and drill pipe joints, applied in drill pipe, drill pipe, drilling equipment and other directions, can solve the problems of increasing the inner diameter channel of drill pipe joints, insufficient sealing performance of joints, incapable of large shear stress, etc., to reduce fatigue The probability of failure, increased torsional resistance, the effect of reducing stress levels and stress concentrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

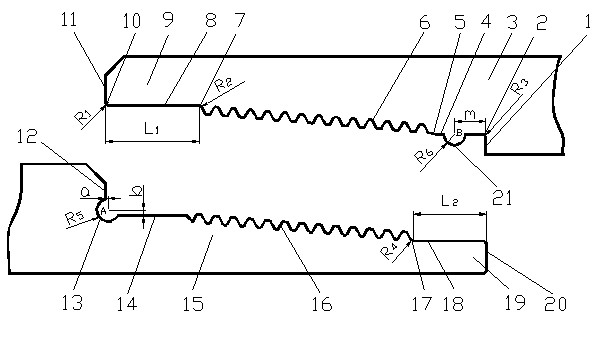

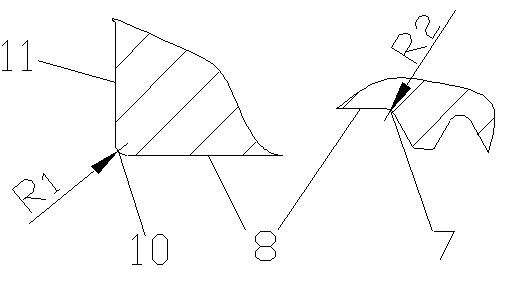

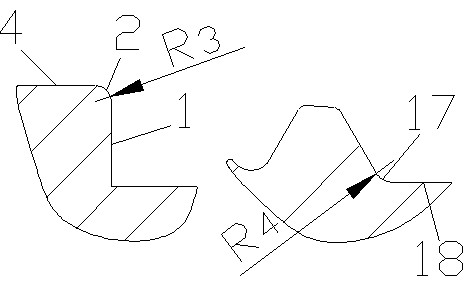

Method used

Image

Examples

Embodiment 2

[0025] Embodiment 2 and embodiment 3 respectively to parameter , , , , , , a, b, , , m have been changed, the values are listed in Table 1, and the unit is mm. Under the same setting parameters, the maximum torque that the API drill pipe joint can withstand is only 98476N×M, while the maximum torque that can be tolerated in Example 1 is 170540N×M, and the maximum torque that can be tolerated in Example 2 is 187594N ×M, the maximum torque that can be tolerated in Example 3 is 178214N×M, and its torsional strength has been increased by at least 73%. Because there are two sealing surfaces in the present invention, the sealing performance of the joint is greatly improved. Therefore, compared with the traditional drill pipe joint, the sealing performance and connection strength of the present invention are greatly improved.

[0026] Table 1 Parameters of 3 embodiments

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com