Reliquefaction device for boil-off gas from liquefied natural gas vehicle gas filling station

A technology for liquefied natural gas and boil-off gas, which is applied in gas/liquid distribution and storage, liquefaction, refrigeration and liquefaction, etc. It can solve problems such as system complexity, reduce resource waste, reduce safety hazards, and protect the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation of the present invention will be further described below in conjunction with accompanying drawing

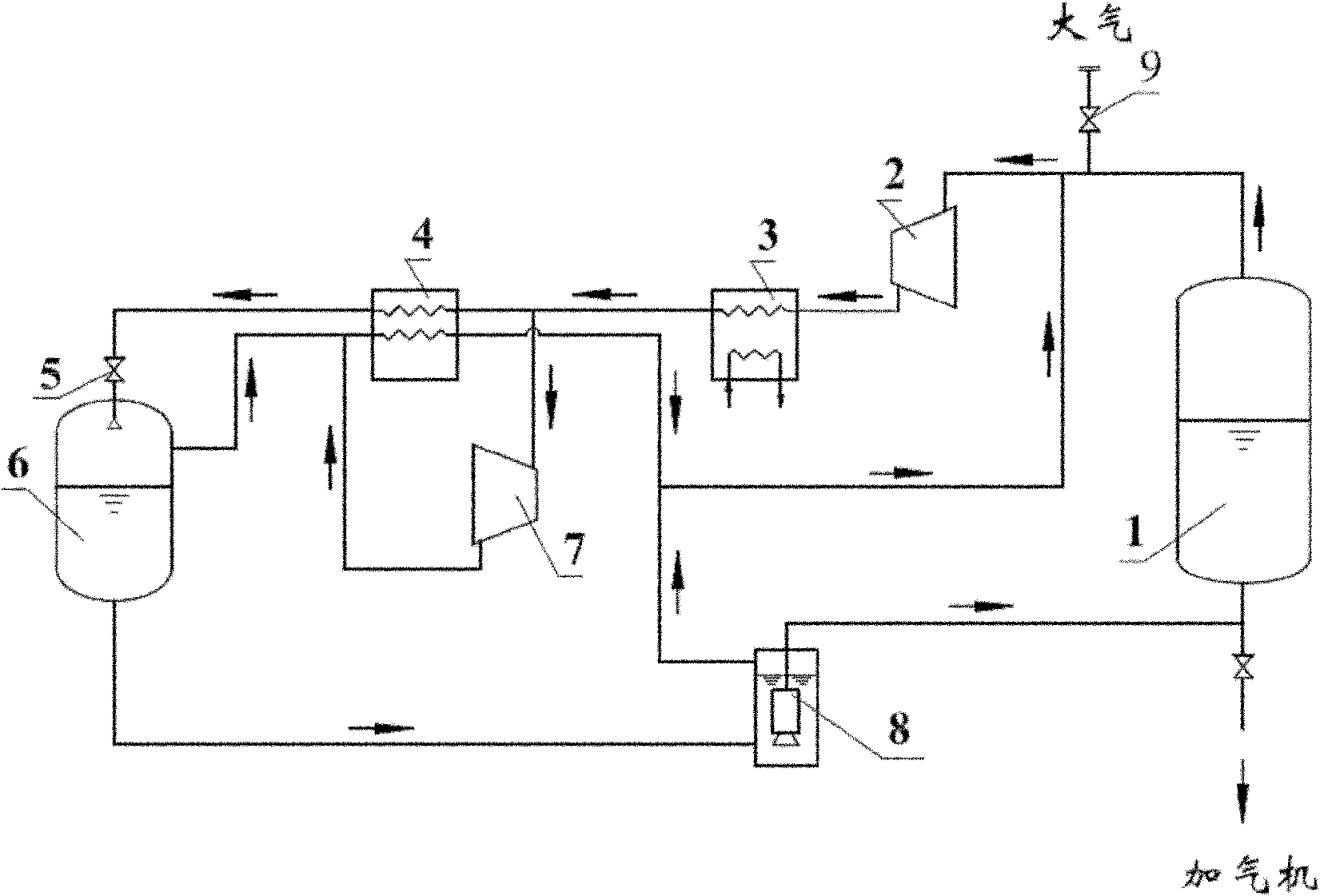

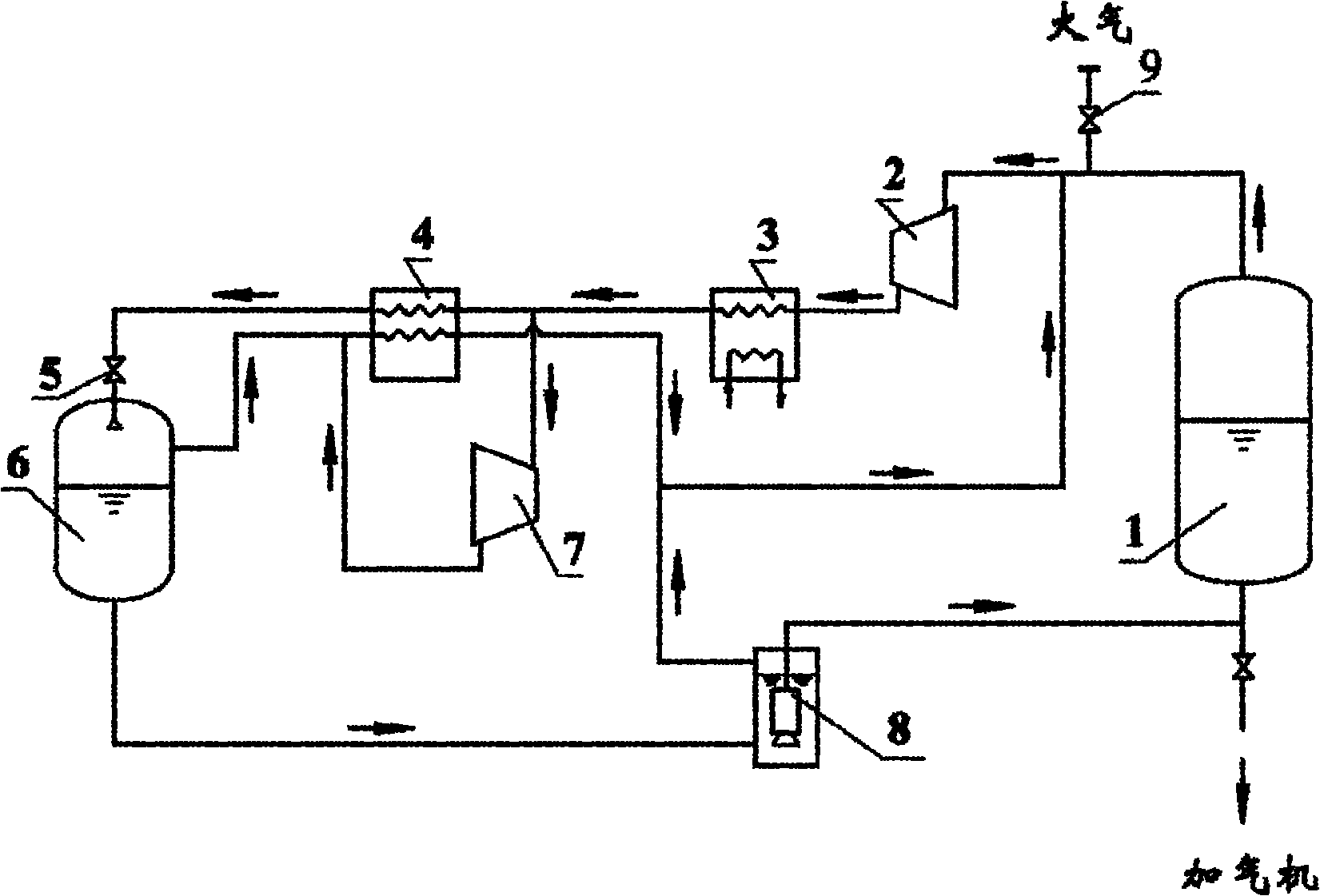

[0015] Such as figure 1 As shown, the present invention includes a gas station storage tank 1, a compressor 2, a cooler 3, a heat exchanger 4, a throttle valve 5, a gas-liquid separator 6, an expander 7, a submersible cryogenic pump 8, a pressure relief Valve 9. The storage tank 1 of the gas filling station is a low-temperature storage tank with a cylindrical double-layer shell structure, which is the main equipment for storing LNG in the gas filling station. The storage capacity of a single storage tank is usually (30-50) m 3 , LNG storage in gas station can adopt single storage tank, double storage tank or multiple storage tanks. Both LNG and BOG are stored in the storage tank, and BOG is above the liquid level of LNG. The gas phase outlet above the storage tank 1 of the gas filling station is connected to the pressure relief valve 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com