FID ignition method and device for chromatographic analysis

An ignition device and chromatographic analysis technology, applied in the field of FID ignition method and device, can solve problems such as safety hazards, flameout, hydrogen leakage, etc., and achieve the effects of ensuring safety, small device size and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

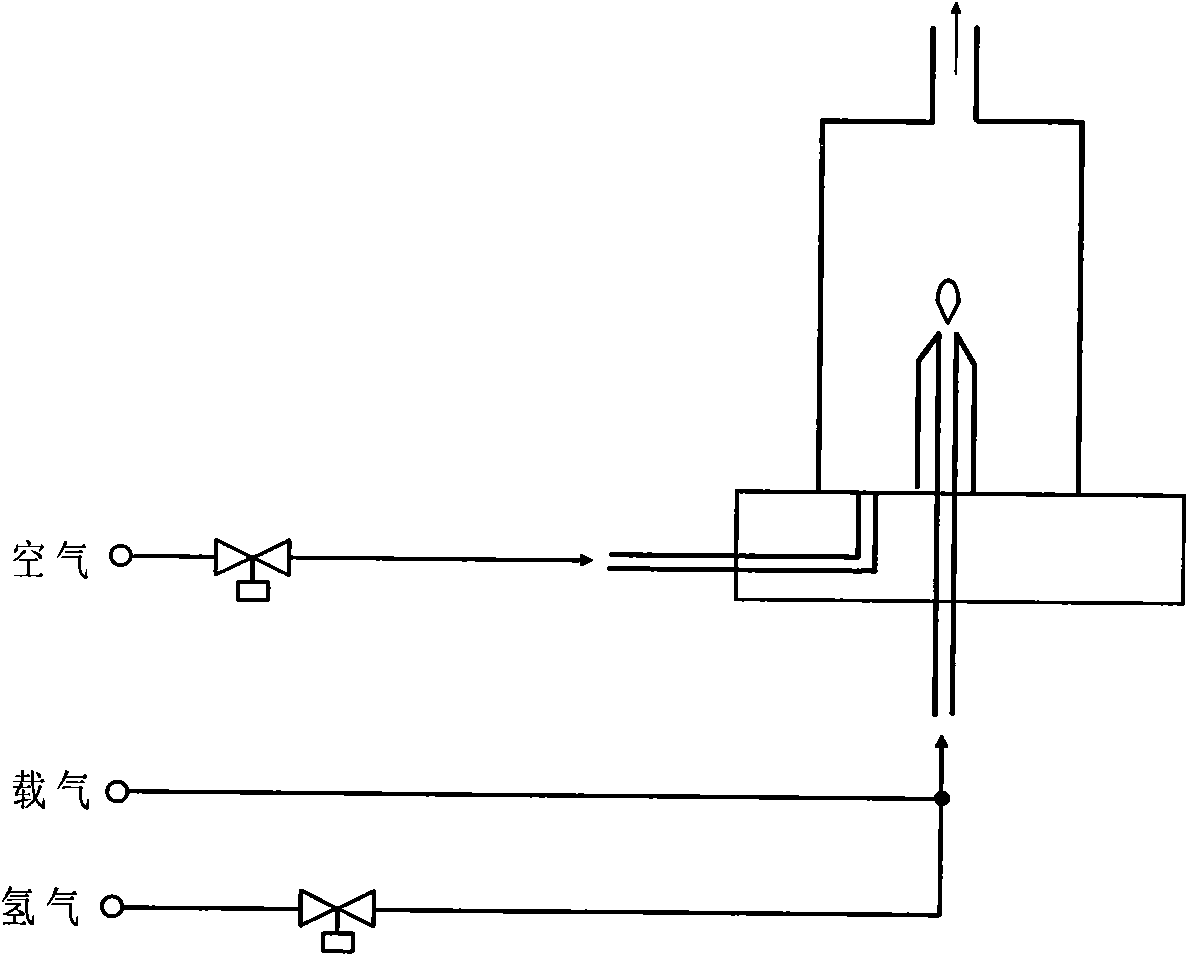

Image

Examples

Embodiment 1

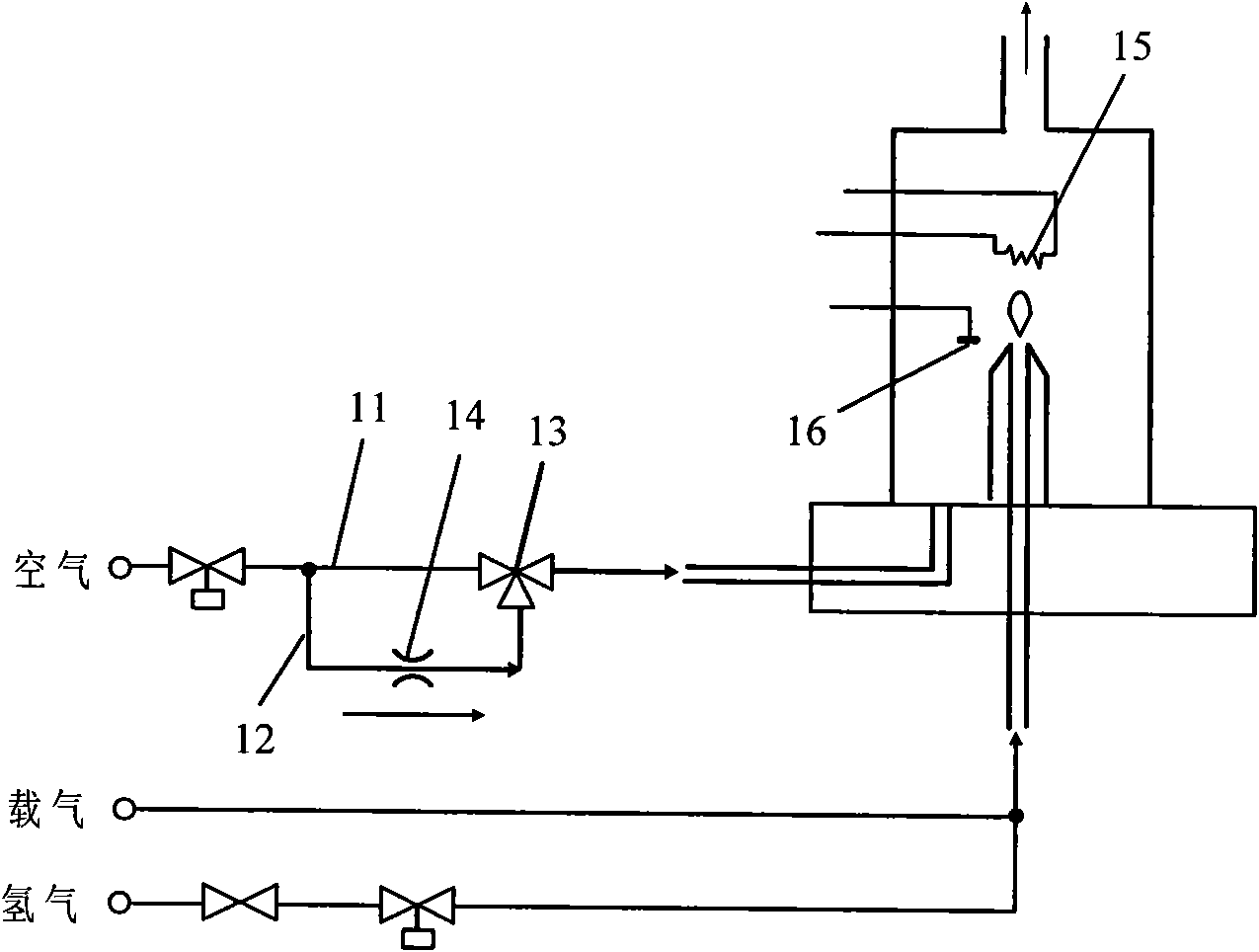

[0041] see figure 2 , 3 , an FID ignition device used in online chromatographic analysis, said device includes a gas channel, an ignition device 15, a monitoring unit and a flow regulation module.

[0042] The gas channels include hydrogen channels, air channels and carrier gas channels.

[0043] The ignition device 15 is arranged in the mixing area of hydrogen and air, and this embodiment adopts a heating wire.

[0044] The monitoring unit includes a monitoring module 16 and a judging module. The monitoring module 16 is set in the mixing area of hydrogen and air for monitoring temperature or optical information. The judging module judges whether it is in an ignition state according to the monitoring information. In this embodiment, the monitoring module uses a temperature detector, such as a thermocouple.

[0045] The flow regulating module is arranged on the hydrogen channel or the air channel, and in this embodiment is arranged on the air channel. The flow regulati...

Embodiment 2

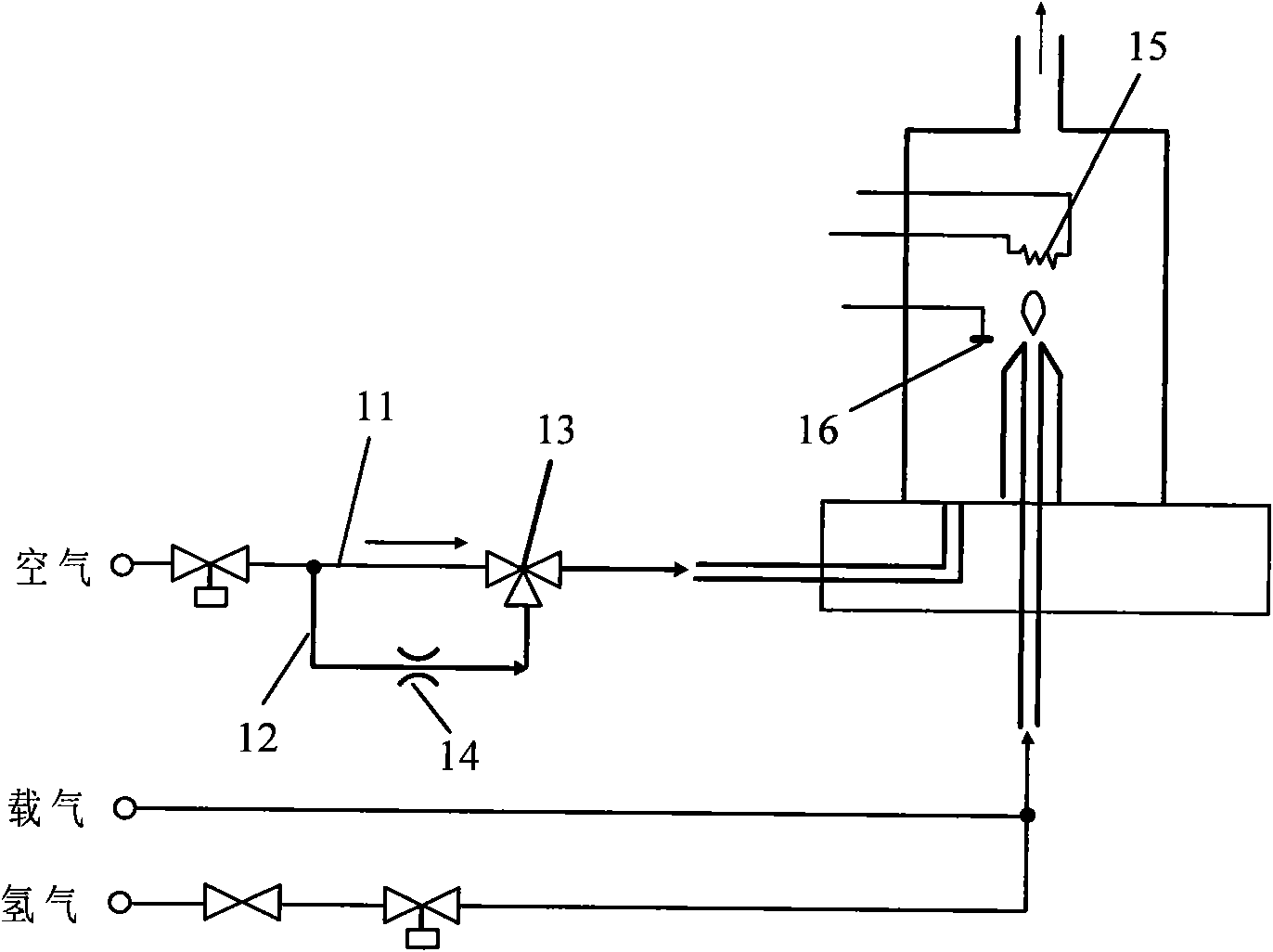

[0059] see Figure 4 , 5 , a kind of FID ignition device, is applied in the online chromatographic analysis, and embodiment 1 difference is:

[0060] 1. The ignition device adopts the discharge element 17 to ignite the hydrogen gas through discharge.

[0061] 2. The flow regulating module is set on the hydrogen channel.

[0062] 3. The monitoring module 18 adopts a light intensity detector.

[0063] This embodiment also discloses a FID ignition method, which is applied in online chromatographic analysis, and the method includes the following steps:

[0064] a. Ignition steps:

[0065] Such as Figure 4 As shown, at the time of ignition, by adjusting the control element 13, hydrogen passes through the first passage 11, which increases the flow ratio of hydrogen to air;

[0066] By controlling the discharge of the ignition device, the hydrogen gas is ignited;

[0067]b. Monitoring steps:

[0068] The light intensity detector monitors the light intensity information in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com