High-temperature superconductive long tape critical current continuous measurement and rewinding device

A continuous critical current and high-temperature superconducting technology, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., can solve the problems of critical current reduction, damage, and large error of the strip, so as to avoid surface icing and have a high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

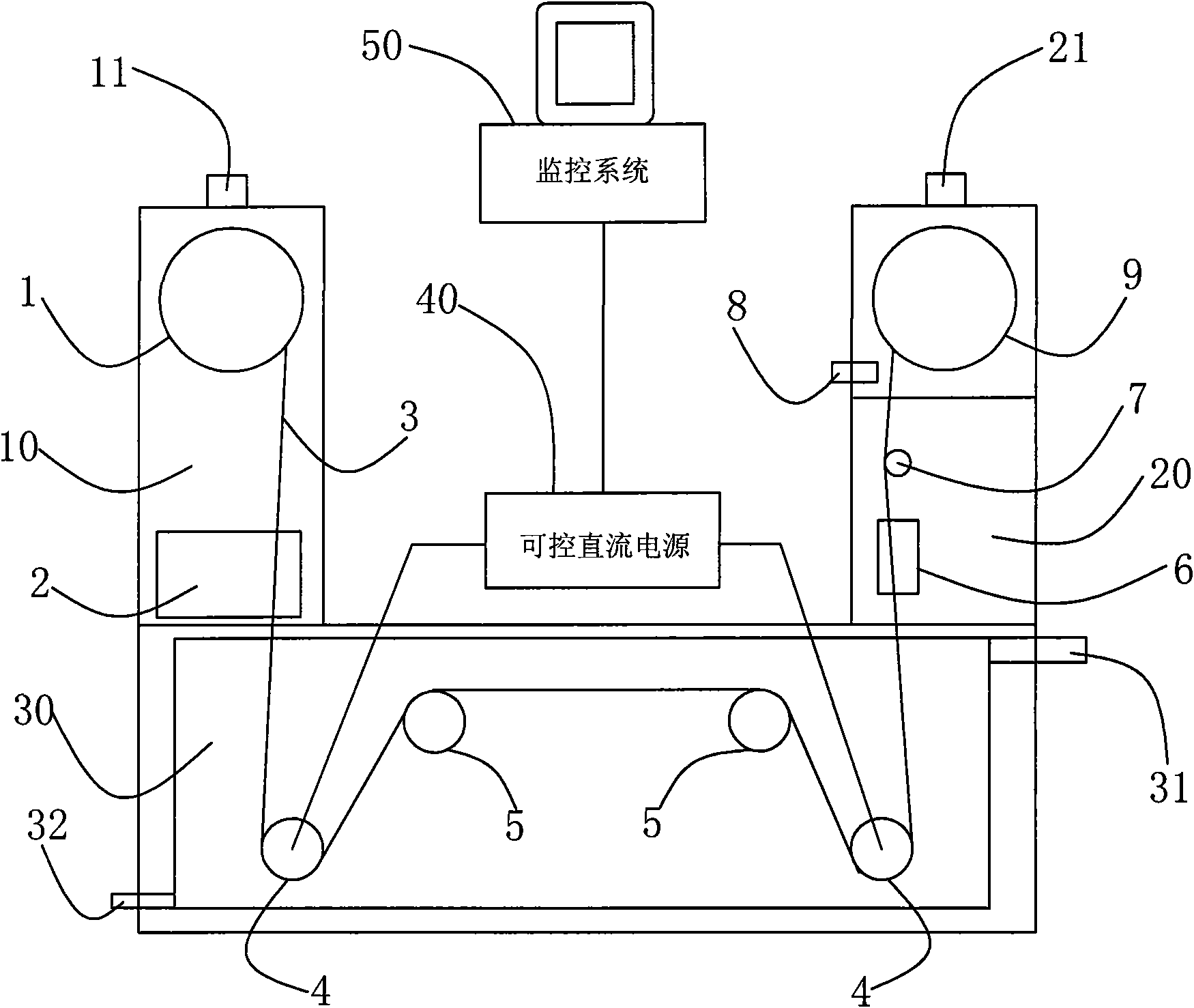

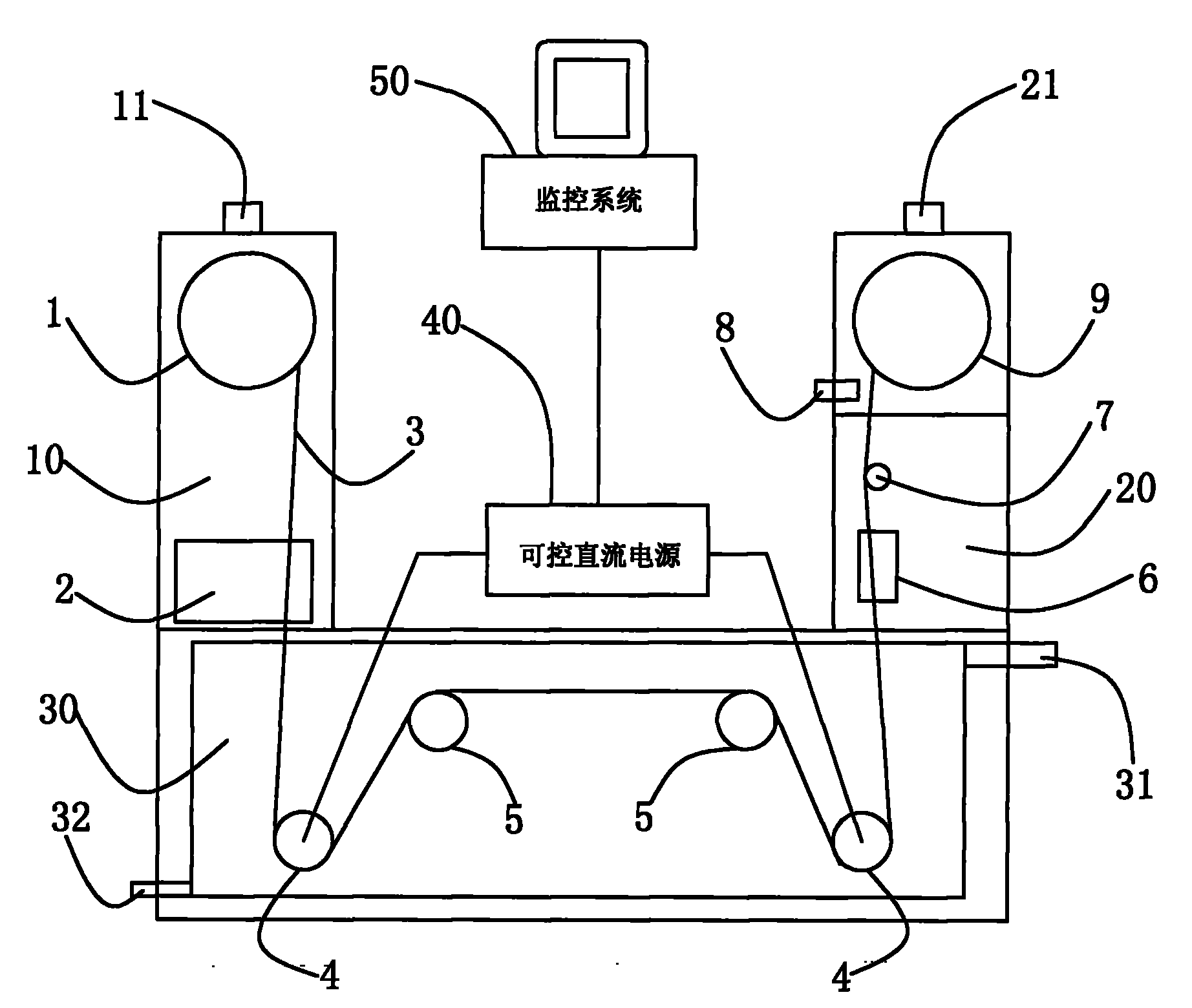

[0028] Such as figure 1 As shown, a high-temperature superconducting strip critical current continuous measurement and rewinding device of the present invention includes a pay-off reel 1 installed in the pay-off box 10, a liquid nitrogen tank 30 and a reel installed in the take-up box 20. The take-up reel 9 and the liquid nitrogen tank 30 are provided with a pair of current lead-in wheels 4 and a pair of signal lead-out wheels 5 .

[0029] The pay-off box 10 and the take-up box 20 are fixed on the top of the liquid nitrogen tank 30, and are respectively located on the left and right sides of the liquid nitrogen tank 30. The top of the liquid nitrogen box 30 is provided with a wire inlet hole and communicates with the interior space of the wire discharge box 10, and the top of the liquid nitrogen box 30 is provided with a wire outlet hole and communicates with the interior space of the wire collection box 20, and the wire discharge box 10 An air outlet 11 is provided at the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com