Strain iron tower drainage system for power transmission line

A technology for transmission lines and iron towers, which is applied in the field of strain-resistant iron tower drainage systems, which can solve problems such as difficulty in keeping wires straight and lace, and achieve the effect of less accessories, simple processing, and beautiful and coordinated appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

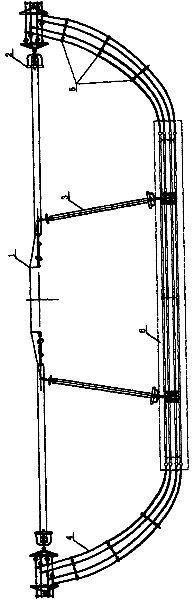

[0021] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, a tension tower drainage system of a power transmission line, the system is composed of drainage soft wire 4, jumper spacer bar 5, aluminum tube cage rigid jumper 6 and jumper insulator string 3, the aluminum tube The cage-type rigid jumper 6 is suspended on the iron tower cross-arm 1 through the jumper insulator string 3, and the two ends of the aluminum tube cage-type rigid jumper 6 are respectively connected with the tension string 2 drainage clamps at both ends of the iron tower cross-arm 1 , and jumper spacer bar 5 is installed additionally and heavy hammer group 12 is installed additionally as required.

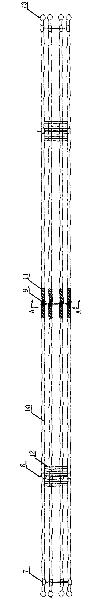

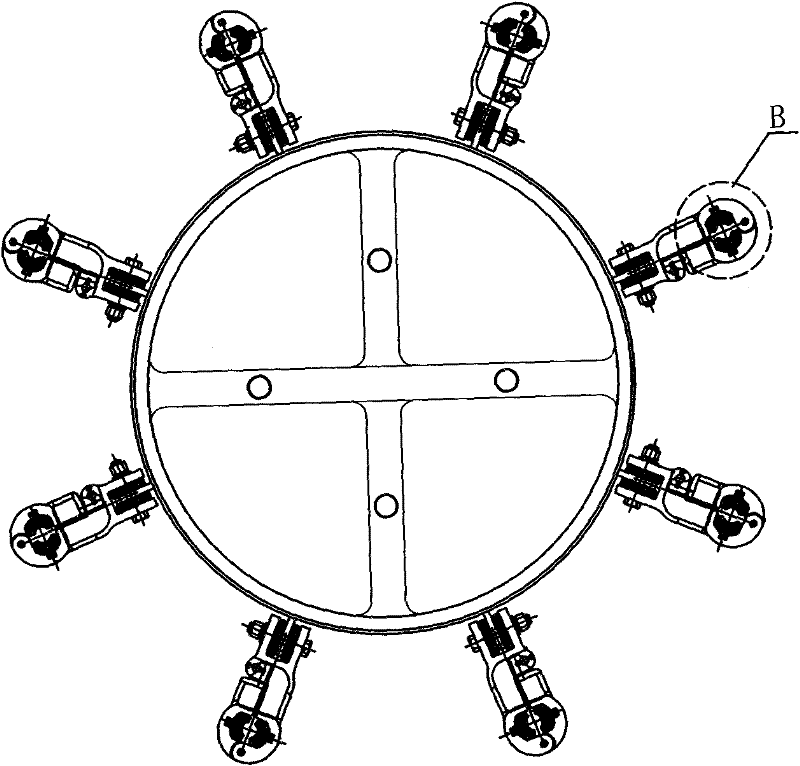

[0022] figure 2 As shown, the aluminum tube cage rigid jumper 6 is a low-noise corona-free aluminum tube cage jumper, which is mainly composed of a drainage soft wire 4, a hollow aluminum alloy tube 10, and aluminum tube spacers 7, 8 , 9, the jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com