Cut, oil & flame resistant glove and a method therefor

A technology of gloves and core sleeves, applied in the field of weight gloves, can solve problems such as fire, short circuit of electrical components, burns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

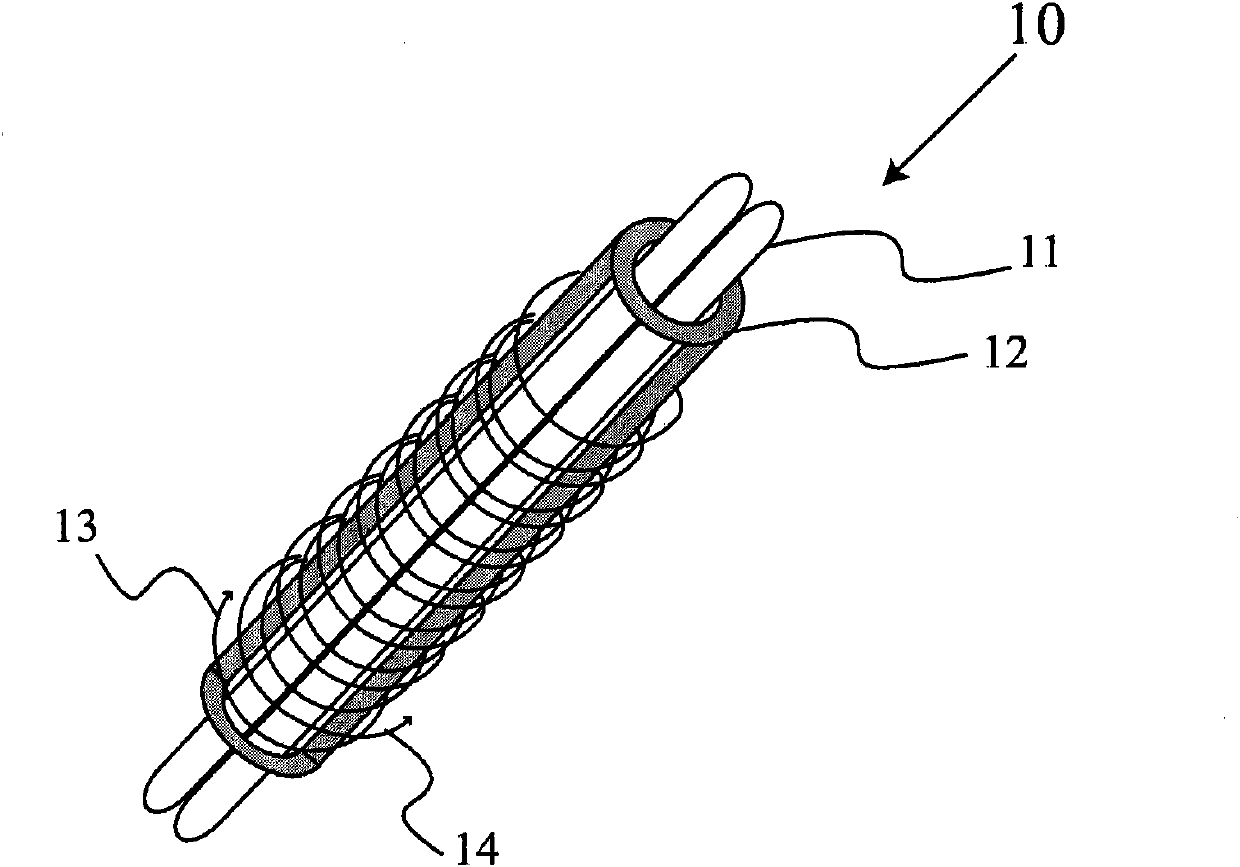

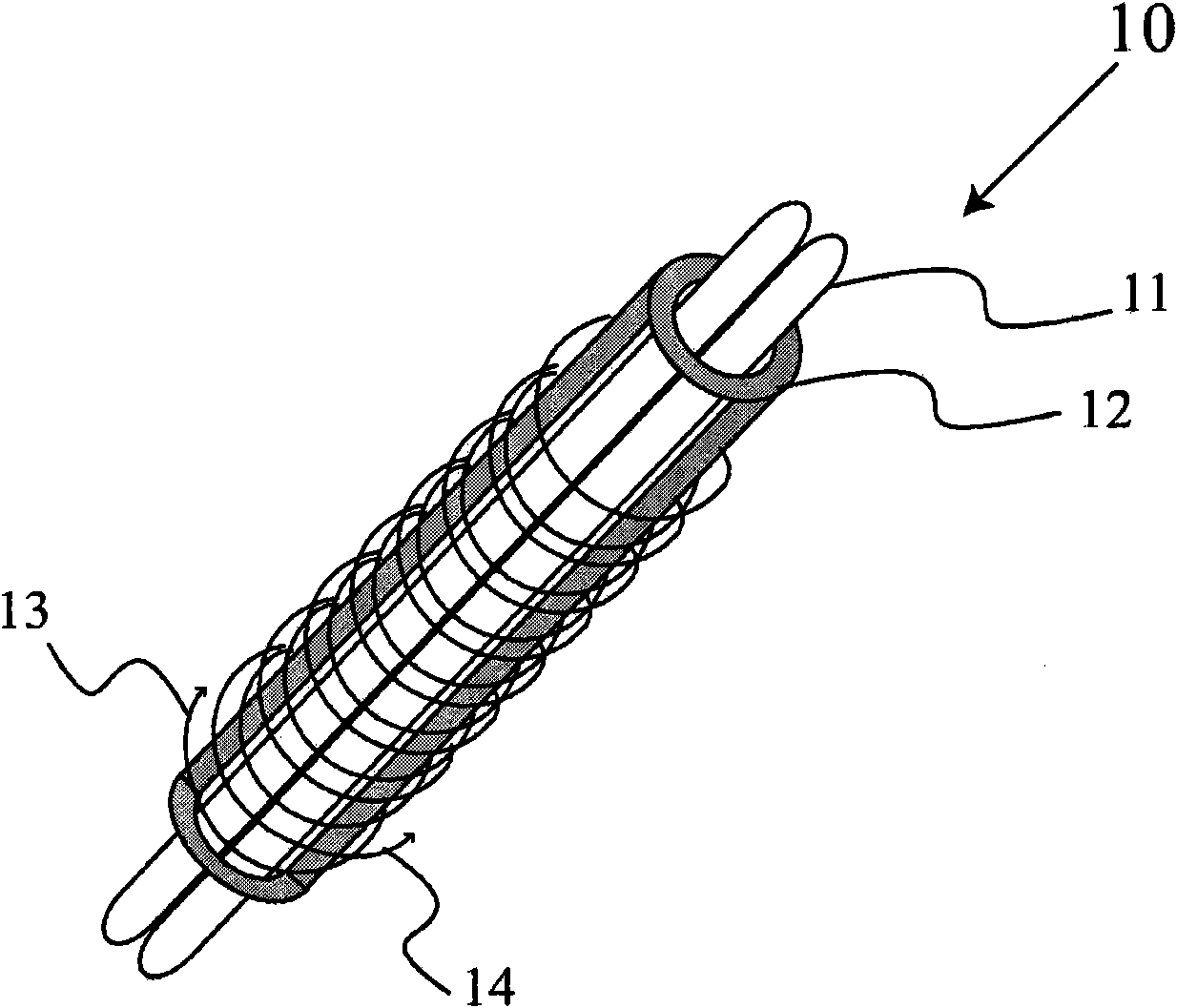

[0024] Knitted glove liners are commonly manufactured using a flatbed knitting machine that uses a plurality of needles in an array of needles and one or more yarns to knit the glove liner. Typically, eight basic components can be used to construct the glove. The eight parts include one part for each of the five fingers, two parts for the palm including upper and lower parts, and one part for the wrist region. All these parts are cylindrical or tapered parts which are interconnected to form the overall anatomical shape of the hand. A conventional knitting process employs a knitting machine to knit each of these areas in a specific order, usually one finger at a time, starting with the little finger and continuing through the ring, middle, and index fingers. After each finger has been knitted with only selected needles in the needle array, the knitting process for that finger is stopped and the yarn is cut and bundled. The knitted fingers are held by the retainer and lowered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com