Optical element, and light source unit and liquid crystal display device provided with the optical element

A technology of optical components and light source units, applied in the field of optical components, can solve the problems of low light extraction efficiency of light diffusion plate, low light utilization efficiency, and difficulty in fully eliminating uneven brightness of backlight, so as to eliminate uneven brightness and improve extraction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

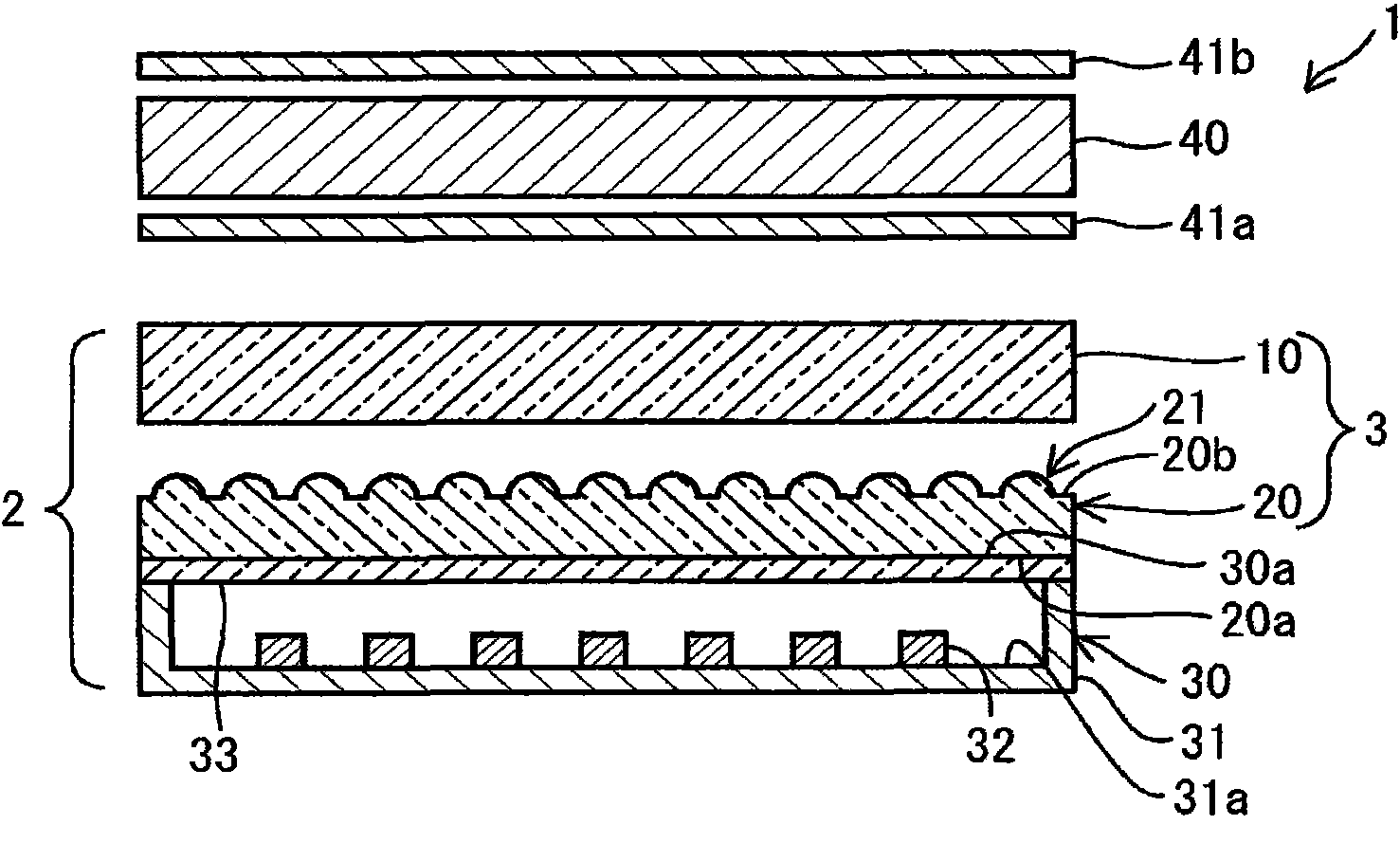

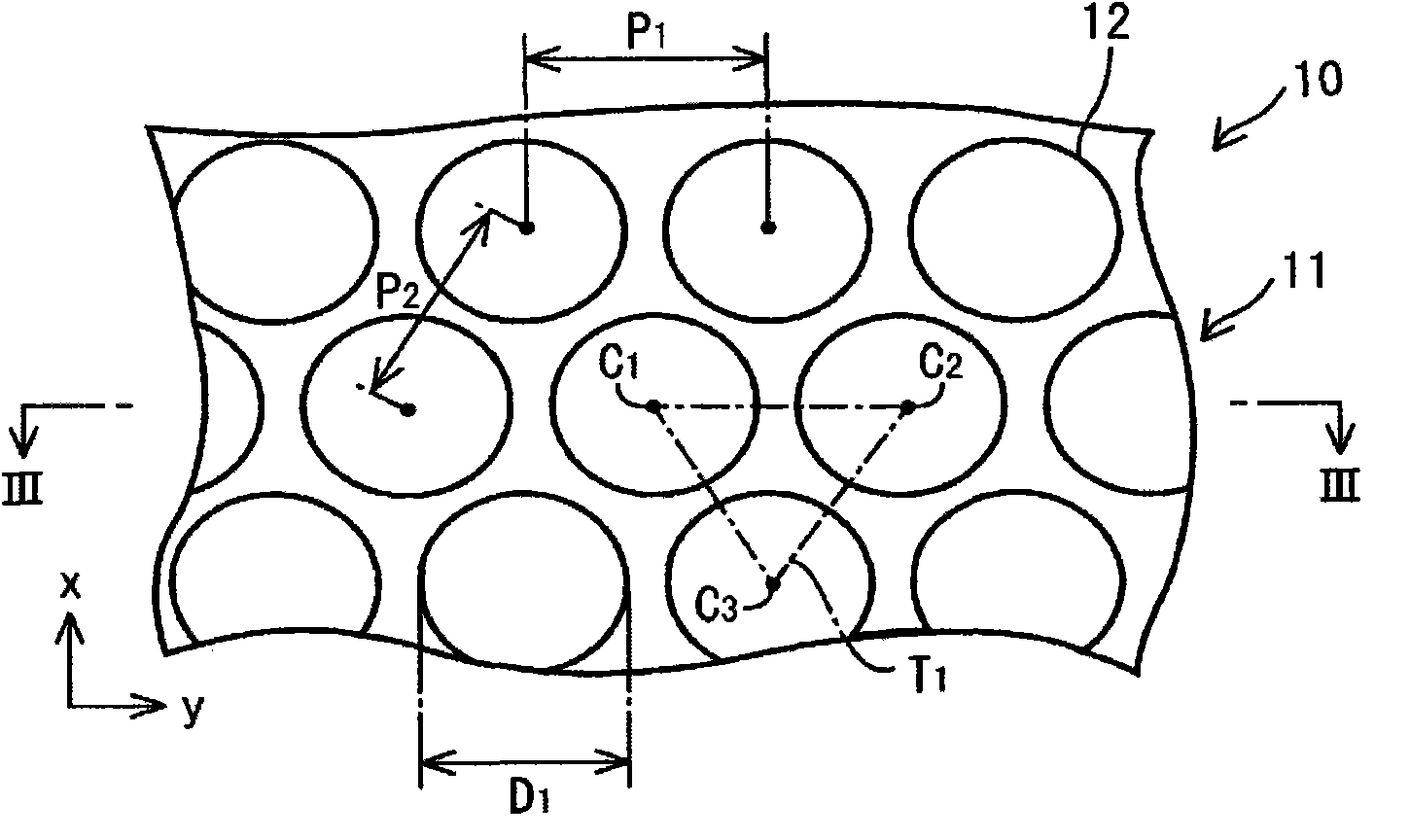

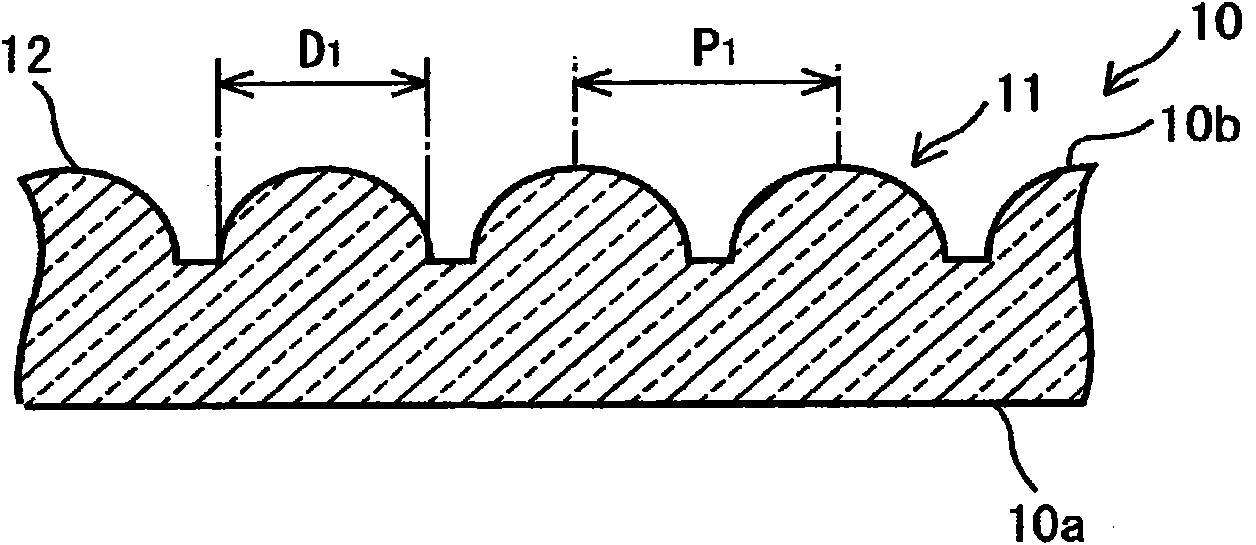

[0137] In the above-mentioned embodiment, the example in which the microlenses 22 are arranged in a so-called regular triangular lattice has been described. However, in the present invention, the arrangement of the microlenses 22 is not limited to a so-called regular triangle arrangement. Such as Figure 13 As shown, the microlenses 22 can also be arranged regularly and periodically in the mutually orthogonal x-direction and y-direction. Such as Figure 13 As shown, when the microlenses 22 are regularly and periodically arranged in the mutually orthogonal x-direction and y-direction, the pitches of the microlens array 21 can be approximately the same in the x-direction and y-direction. Therefore, the light diffusion performance of the optical plate 20 in the x direction and the light diffusion performance of the optical plate 20 in the y direction can be made substantially the same.

Deformed example 2

[0139] In the above implementation, an example in which the light source device 30 has a plurality of point light sources 32 has been described. However, in the present invention, the kind of light sources provided in the light source device 30 is not limited to point light sources. For example, Figures 14 to 15 As shown, for example, the light source device 30 may be a component having a plurality of linear light sources 34 arranged in parallel. The linear light source 34 is not particularly limited. For example, the linear light source 34 may be a cold cathode fluorescent lamp (Cold Cathode Fluorescent Lamp: CCFL) or the like.

Deformed example 3

[0141] In the above embodiment, the example in which the microlens array 21 having the plurality of convex microlenses 22 is formed on the light exit surface 20b of the optical plate 20 has been described. However, in the present invention, the microlens 22 may also have a concave shape. Furthermore, the microlens array 21 may also be formed on the light incident surface 20 a of the optical plate 20 . The microlens array 21 may be formed on both surfaces of the light exit surface 20 a and the light incident surface 20 a of the optical plate 20 .

[0142] Specifically, as Figure 16 As shown, for example, a microlens array 21 having a plurality of microlenses 25 formed in a concave shape may be formed on the light incident surface 20 a of the optical plate 20 .

[0143] (Other modifications)

[0144] At least one of a plurality of optical plates 20 and light diffusion plates 10 may also be arranged. That is, the number of objects to arrange each of the optical plate 20 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com