Method and equipment for preparing tissue engineering scaffold with anisotropic pore structure

A tissue engineering scaffold and anisotropic technology, applied in medical science, prosthesis, etc., can solve problems such as difficulty in meeting application requirements, and achieve the effect of easy implementation, simple equipment structure, and promotion of tissue repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

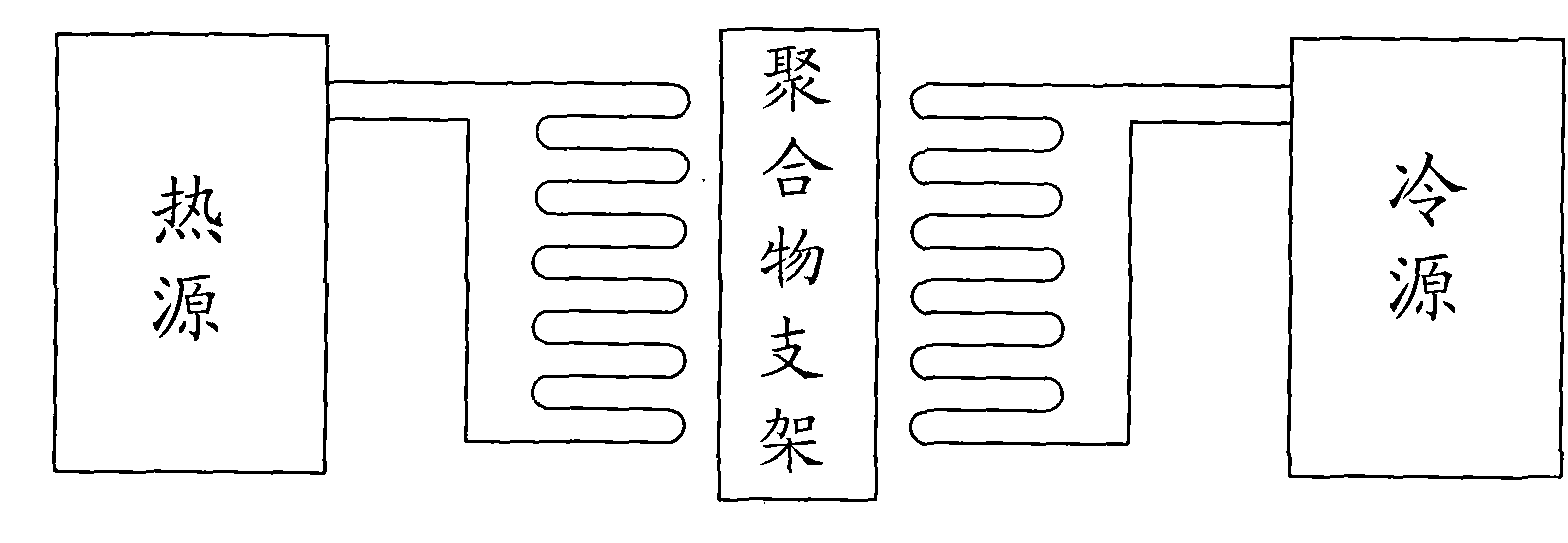

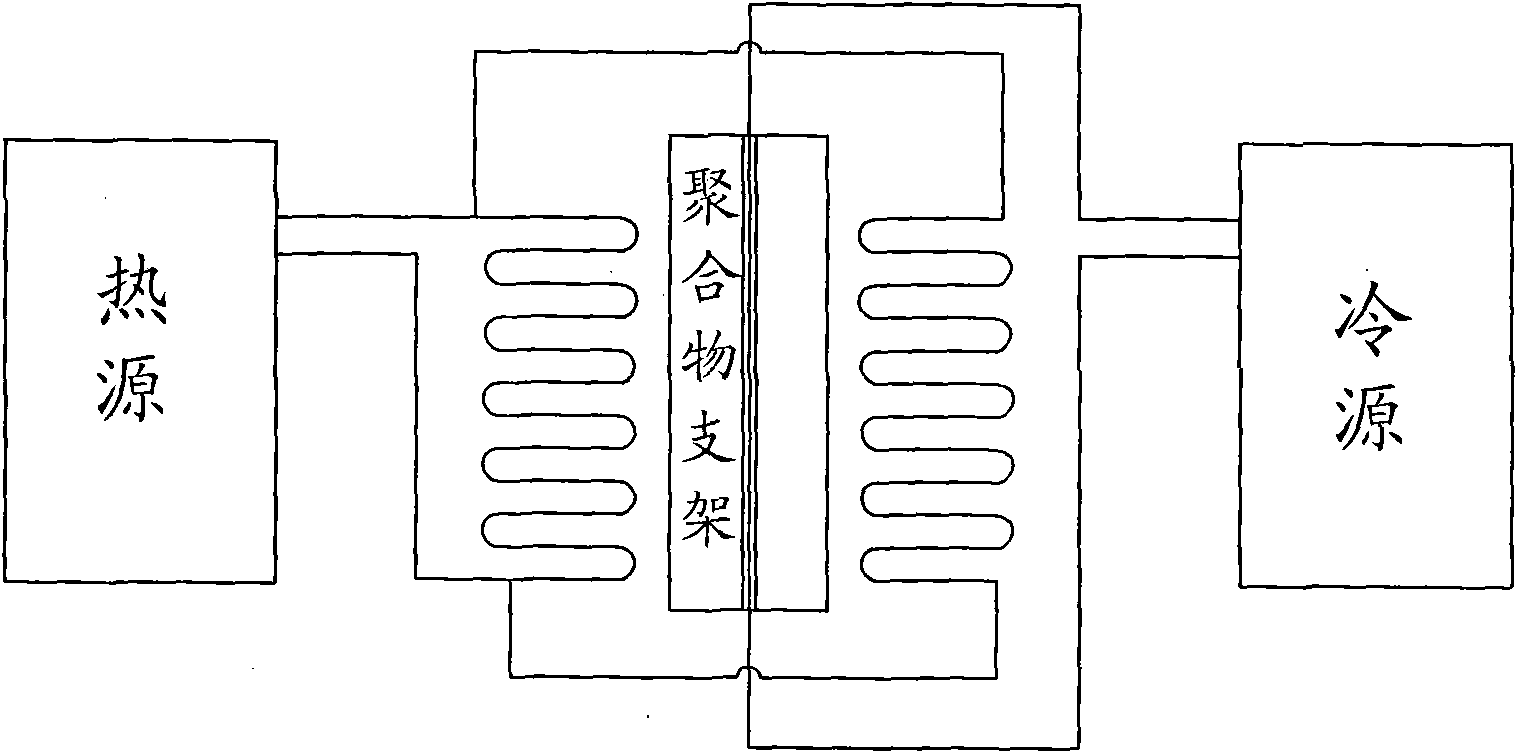

[0029] refer to Figure 1 to Figure 4 , a method for preparing a tissue engineering scaffold with anisotropic pore structure of the present invention, comprising the following steps:

[0030] (a), the polymer is made into a solution, mixed with a porogen, and placed in the cavity of the equipment core;

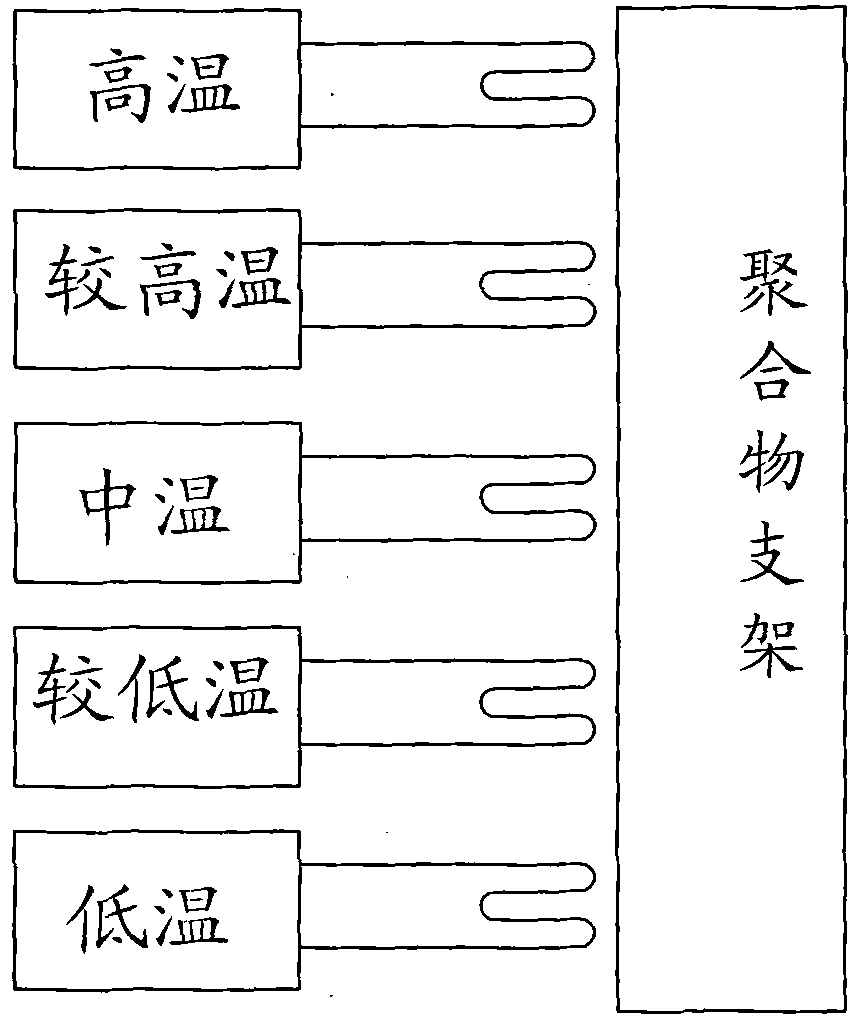

[0031] (b), according to actual needs, divide the outside of the core into at least two temperature zones, and feed heat exchangers of various temperatures into these temperature zones, so that the temperature of the material in the core changes and the polymer solution produces phase separation;

[0032] (c) Fixing the polymer during phase separation as required, removing the porogen added in step (b), and drying to obtain a porous scaffold.

[0033] In the method, the polymer solution and the porogen are subjected to zoned heat exchange, so that the precise and anisotropic distribution of the pores and pore diameters on the obtained scaffold can be realized, and the tissue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com