Degradable toothbrush main material with self-cleaning function

A main material and self-cleaning technology, applied in the field of toothbrush main materials, can solve problems such as unsafe, unhealthy human body, poor biocompatibility, etc., and achieve the effect of repairing and protecting the oral cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

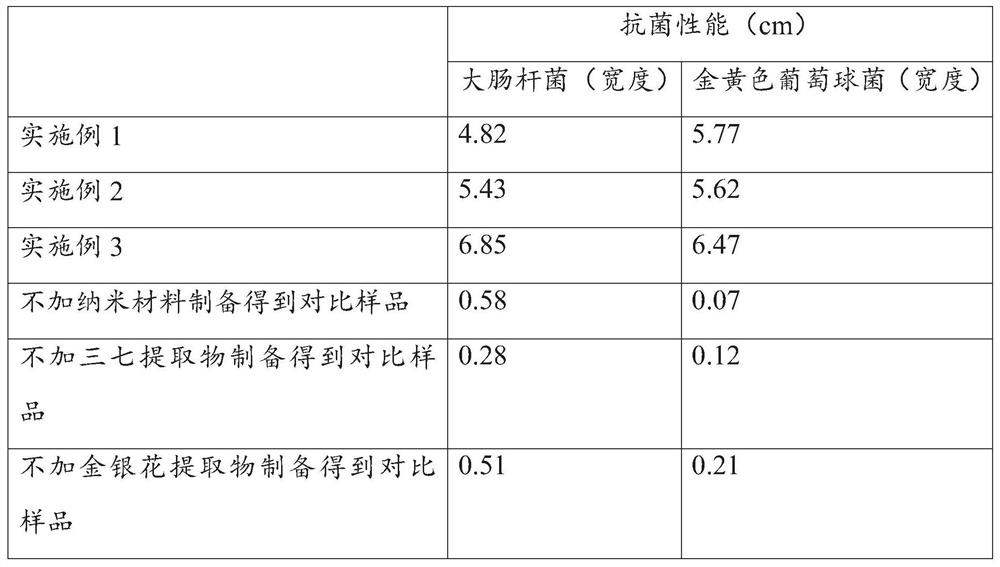

Examples

preparation example Construction

[0052] The preparation process of Panax notoginseng extract is as follows: take Panax notoginseng and break the wall, add cellulase and maltase at a mass ratio of 100:1:1, seal and enzymolyze at room temperature for 10-25 hours to obtain the enzymatic hydrolyzate; The hydrolyzate was placed in ethanol and extracted more than 3 times to obtain an extract, and concentrated to obtain a Panax notoginseng extract;

[0053] The preparation process of the honeysuckle extract is as follows: take the honeysuckle and break the wall, add cellulase and maltase at a mass ratio of 100:1:1, seal the enzymolysis at room temperature for 10-25 hours, and obtain the enzymatic hydrolyzate; take the enzymatic hydrolyzate and place Extract in ethanol more than 3 times to obtain the extract, concentrate to obtain the honeysuckle extract;

[0054] The preparation process of carboxymethyl chitosan solution is as follows: dissolve carboxymethyl chitosan in water, add 3% sodium bicarbonate solution, and...

Embodiment 1

[0056] A degradable and self-cleaning toothbrush main material, the specific preparation process is as follows:

[0057] 1) Take 6 parts of nano-titanium dioxide with a particle size of 30nm, 6 parts of biotin, 2 parts of lysine, 6 parts of Panax notoginseng extract, and 5 parts of honeysuckle extract, and add them to a solution containing 30 parts of chitosan, at 40 ° C Stir slowly in a constant temperature water bath until the mixture is uniform, and adjust the pH to 3.5 with lactic acid to obtain a mixed solution A;

[0058] 2) Swell 20 parts of collagen in a solution containing 40 parts of carboxymethyl chitosan, stir and mix at 5°C, and continue stirring for 12 hours after fully swelling to obtain a mixed solution B;

[0059] 3) Mix mixed solution A, mixed solution B and 60 parts of PBAT evenly, pour into SBF solution, keep warm at 60°C, add 0.5 parts of glutaraldehyde, and obtain a textile material after reaction;

[0060] 4) Add 80 parts of textile materials, 20 parts ...

Embodiment 2

[0064] A degradable and self-cleaning toothbrush main material, the specific preparation process is as follows:

[0065] 1) Take 8 parts of nano-titanium dioxide with a particle size of 50nm, 8 parts of biotin, 3 parts of lysine, 8 parts of Panax notoginseng extract, and 7 parts of honeysuckle extract, and add them to a solution containing 35 parts of chitosan. Stir slowly in a constant temperature water bath until the mixture is uniform, and adjust the pH to 4.3 with lactic acid to obtain a mixed solution A;

[0066] 2) Swell 25 parts of collagen in a solution containing 35 parts of carboxymethyl chitosan, stir and mix at 6°C, and continue stirring for 20 hours after fully swelling to obtain mixed solution B;

[0067] 3) Mix mixed solution A, mixed solution B and 60 parts of starch evenly, pour into SBF solution, keep warm at 65°C, add 0.8 parts of glutaraldehyde, and obtain a textile material after reaction;

[0068] 4) Add 70 parts of textile materials, 18 parts of polybut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com