Patents

Literature

39results about How to "Appropriate sweetness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

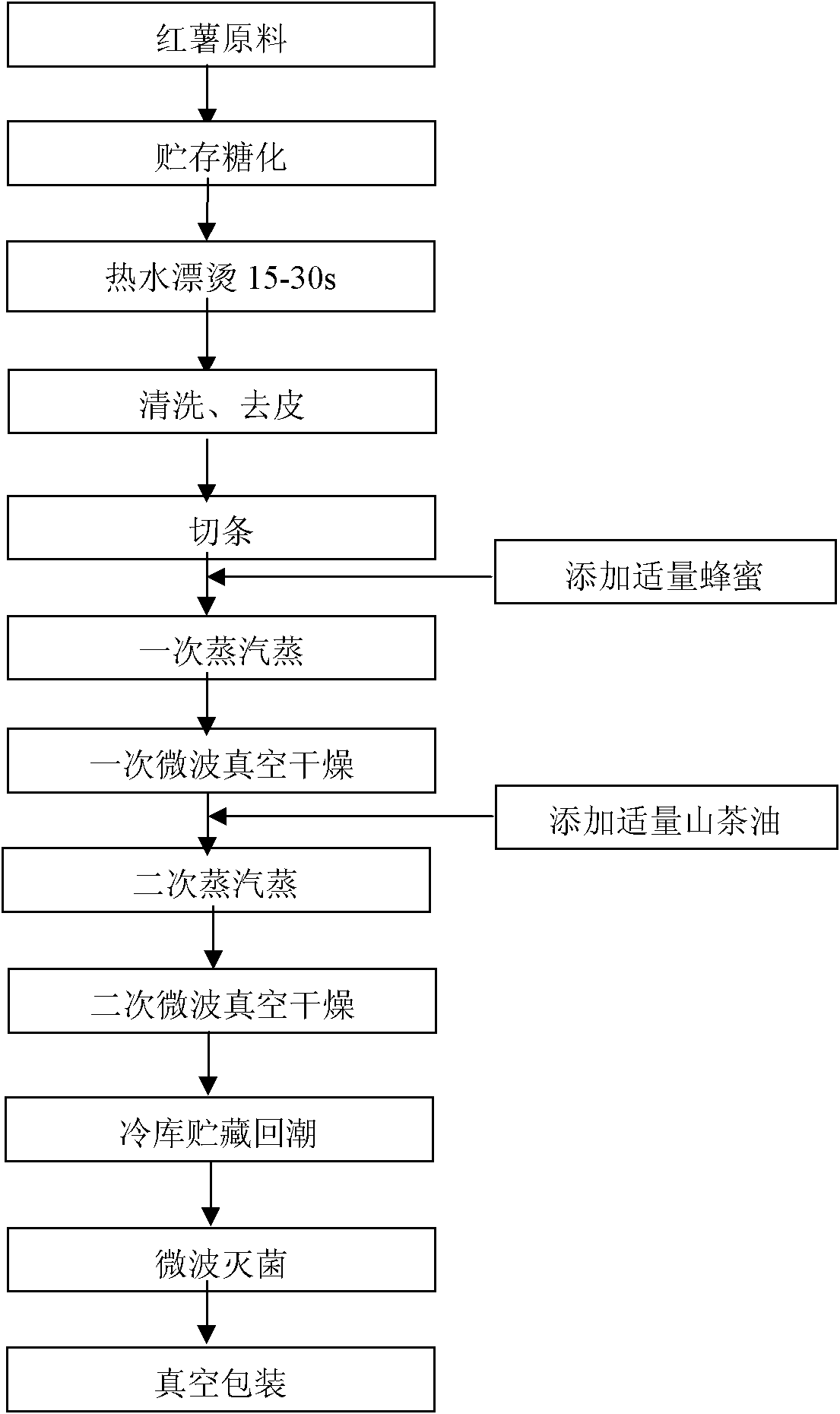

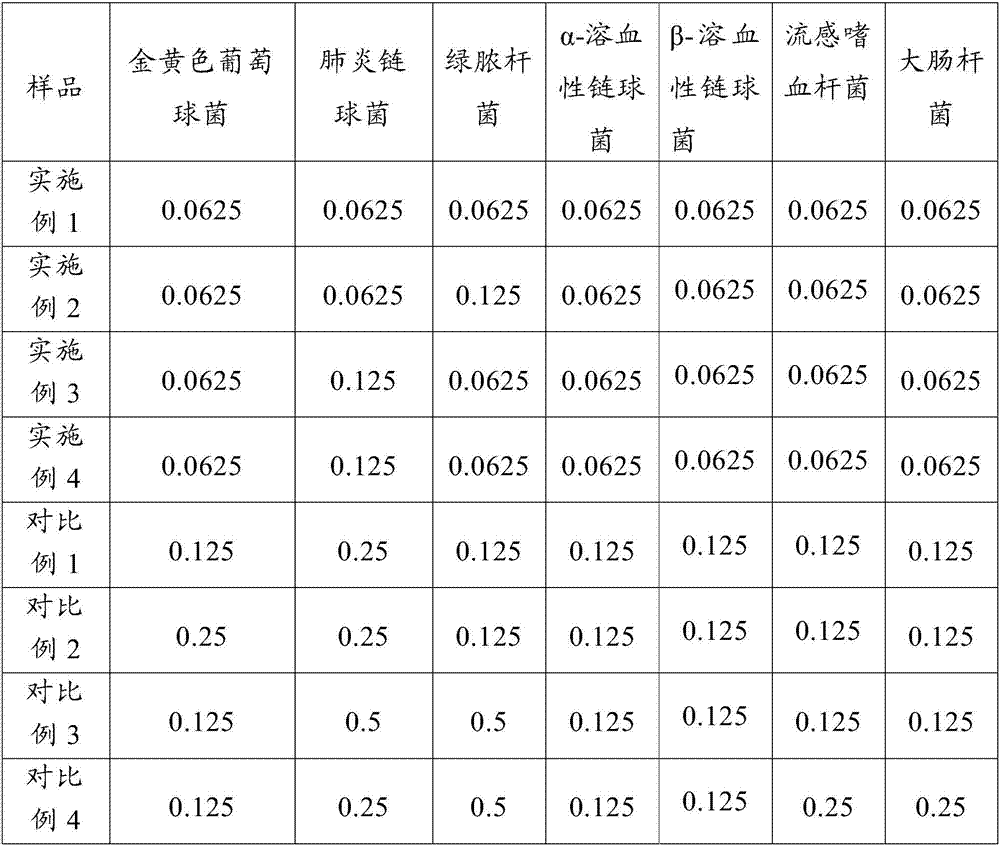

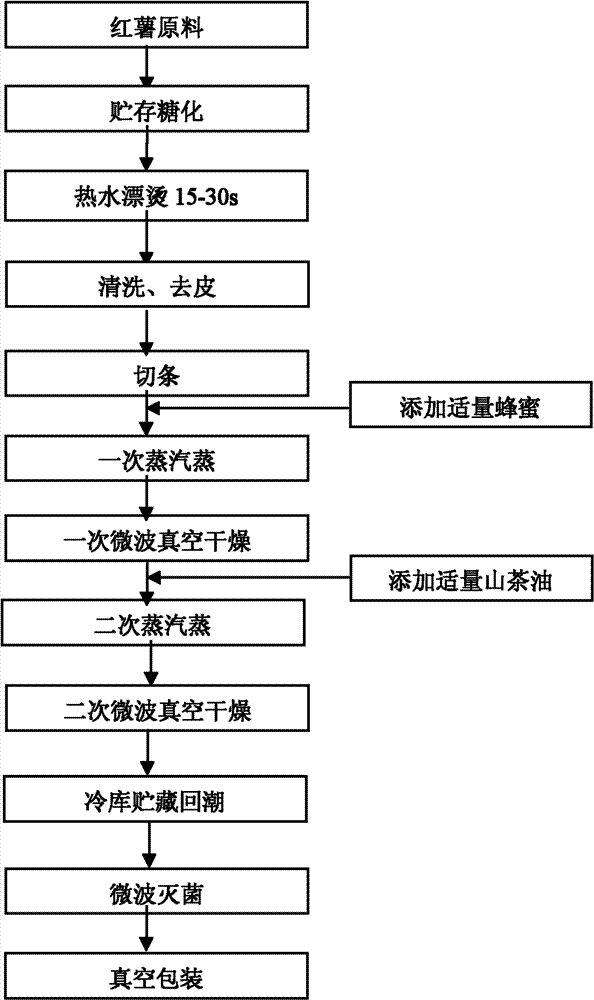

Method for processing instant dried sweet potato

The invention provides a method for processing an instant dried sweet potato, which comprises the following steps of: carrying out storage and saccharification pretreatment on a fresh sweet potato; cleaning the sweet potato, removing the peel of the fresh sweet potato and cutting the sweet potato into strips; blanching for 15-30 seconds; leaching; adding 1-3 percent by mass of honey; steaming for 30-45 minutes in steam; drying to the water content of 32-36 percent at 60-70 DEG C in microwave vacuum; adding 0.2-0.4 percent by mass of mountain naphthalene oil; steaming for 15-30 minutes in steam; drying to the water content of 14-18 percent at 50-60 DEG C in microwave vacuum; storing and dampening to the water content of 20-24 percent at 4-8 DEG C in a refrigeration house; and carrying out microwave sterilization at 30-40 DEG C for 3-6 minutes; and packaging in vacuum. By adopting the processing method of the invention, the produced instant dried sweet potato has flexible texture and certain toughness and can be chewed by all people regardless of age and sex; the product has uniform color, presents red gloss and has the potato flavor deserved by the variety, palatable sweetness, no any food additive, short vacuum microwave drying time and less loss of nutrition components; the product has the normal temperature quality guarantee period for 9 months and the refrigeration quality guarantee period for 12 months; the quality standard of the product meets the following condition: the total bacterial amount is not more than 1,000 CFU / g, the mould is not more than 50 CFU / G, the escherichia coli is not more than 30 MPN / 100g, and pathogenic bacteria are not detected; in addition, the energy consumed for producing the instant dried sweet potato is reduced by more than 30 percent compared with the energy consumed for producing the instant dried sweet potato by hot air drying.

Owner:ZHEJIANG UNIV OF TECH

Processing technique for potato crunchy candy slices

InactiveCN104757233ACrispy and crispyAppropriate sweetnessConfectionerySweetmeatsMouthfeelNutritious food

The invention discloses a processing technique for potato crunchy candy slices, and belongs to the field of food processing. The processing technique is characterized in that the processing technique flow comprises the following steps: potato preparation, cleaning, slicing, rinsing, boiling, drying, frying, sugar coating, and cooling and packaging. The processing technique has the beneficial effects that the product is fragrant and crisp, and proper in sweetness, and has the peculiar sweet flavour of potato; the product is quite high in nutritional value, rich in many nutritional substances including proteins, vitamins and the like, and beneficial for human body to digest and absorb foods and enhancing the immunologic function of human body, has the effects of strengthening spleen and harmonizing stomach, tonifying qi and regulating middle energizer, detoxifying and beautifying skin, reducing pressure and resisting ageing, is a pollution-free nutritional food which is suitable for people of all ages, and economical and practical, as well as is low in water content and suitable for being preserved for a long time.

Owner:赵慧

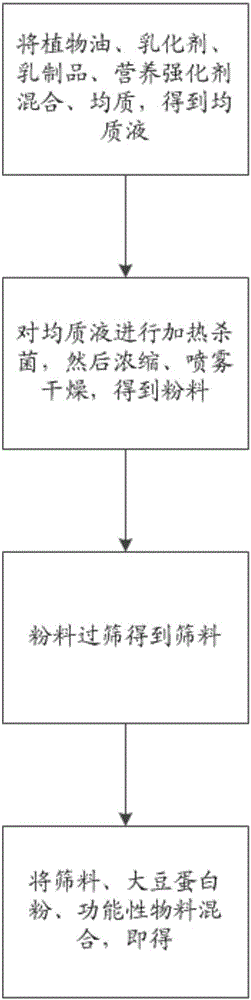

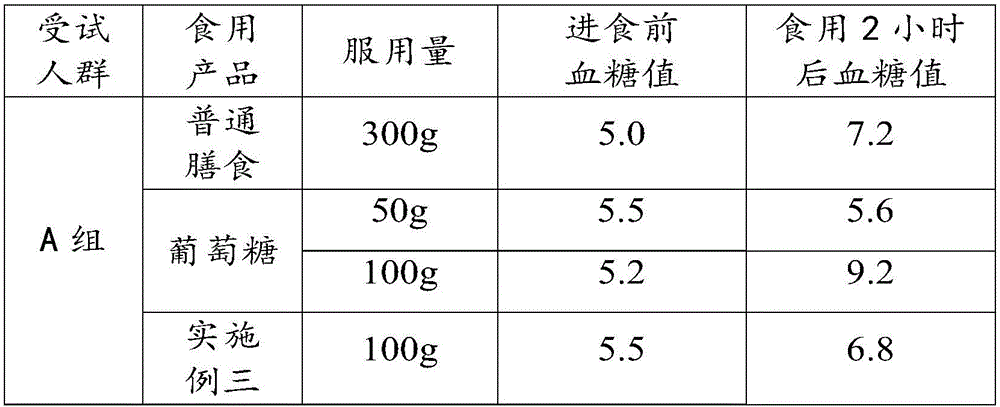

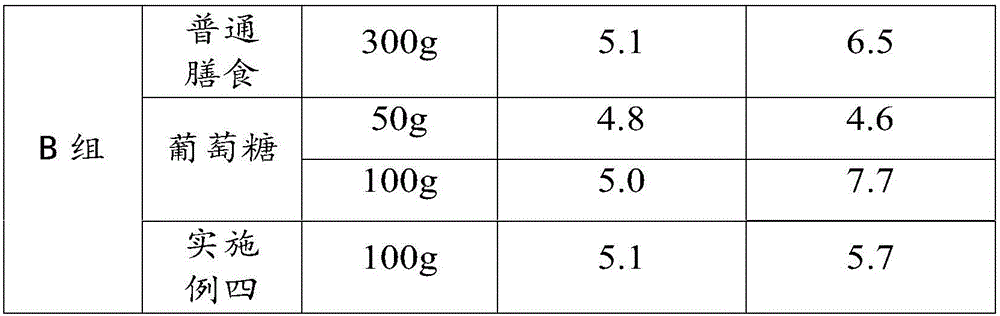

Nutritionally balanced food and preparation method thereof

InactiveCN105747220ARich in nutrientsGreat tasteFood ingredient as antioxidantVegetable oilWhey protein powder

The invention provides a nutritionally balanced food and a preparation method thereof and belongs to the field of food.The nutritionally balanced food comprises, by weight, 30-60 parts of dairy products, 8-18 parts of vegetable oil, 5-15 parts of soybean protein powder and 16-40 parts of functional materials, wherein the dairy products include one or more of fresh milk, whole milk powder, whey powder, whey protein powder and skim milk powder, the vegetable oil includes one or more of soybean oil, coconut oil, corn oil, rapeseed oil and sunflower seed oil, and the functional materials include one or more of kudzuvine root powder, pumpkin powder, xylitol, isomaltitol and sunflower seed oil.The nutritionally balanced food containing the dairy products, the vegetable oil, the functional materials and the like is reasonable in nutrition combination to achieve balanced nutrition.

Owner:北安宜品努卡乳业有限公司

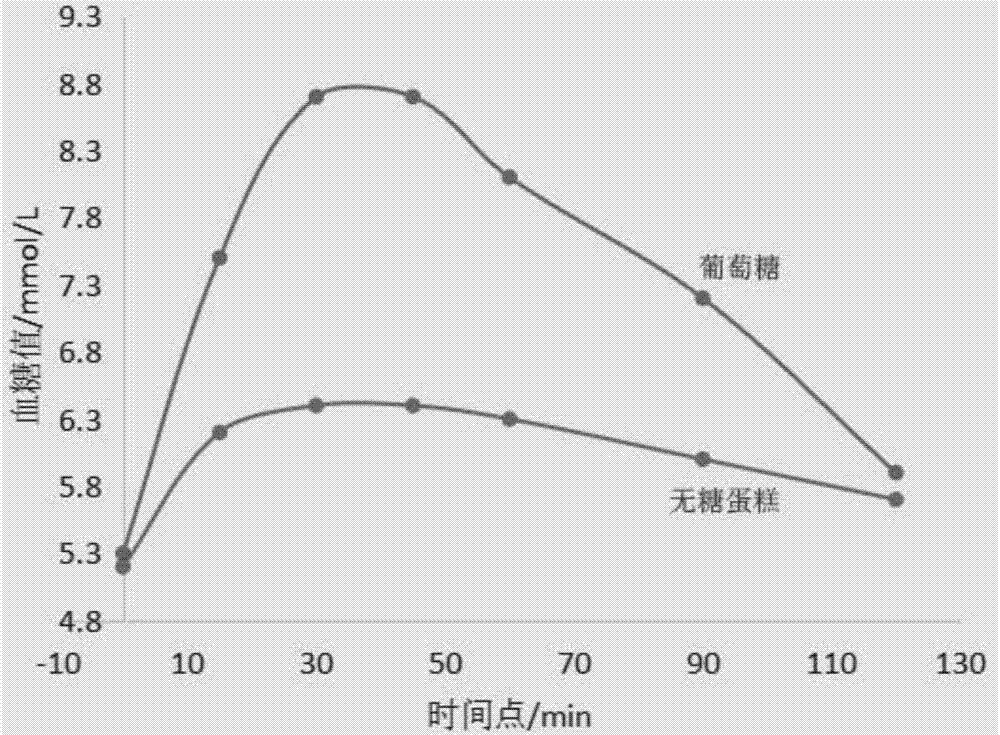

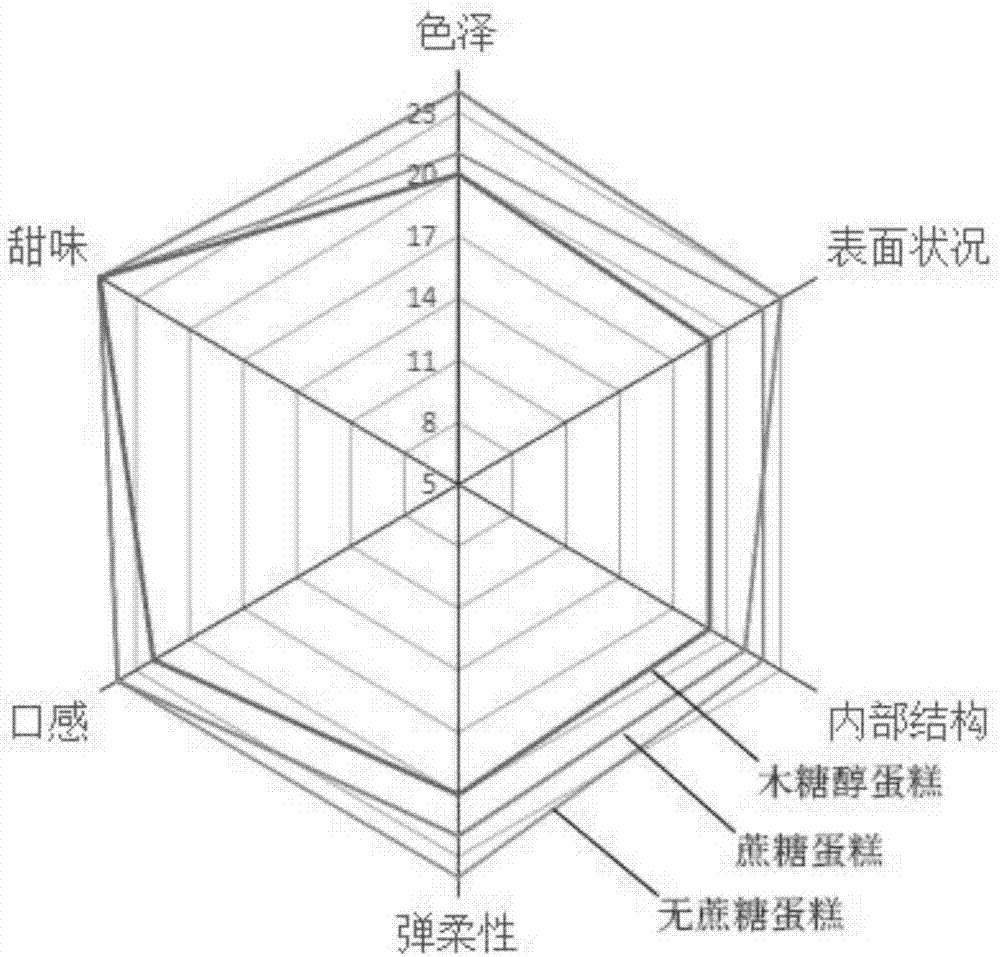

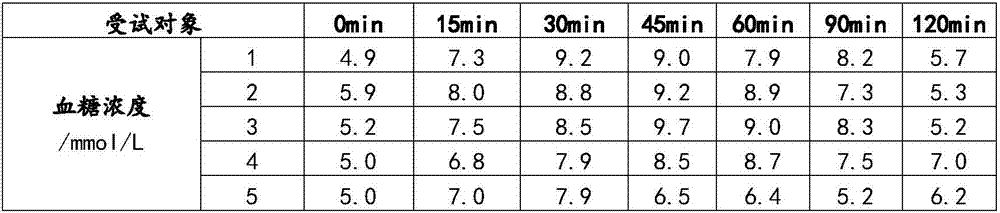

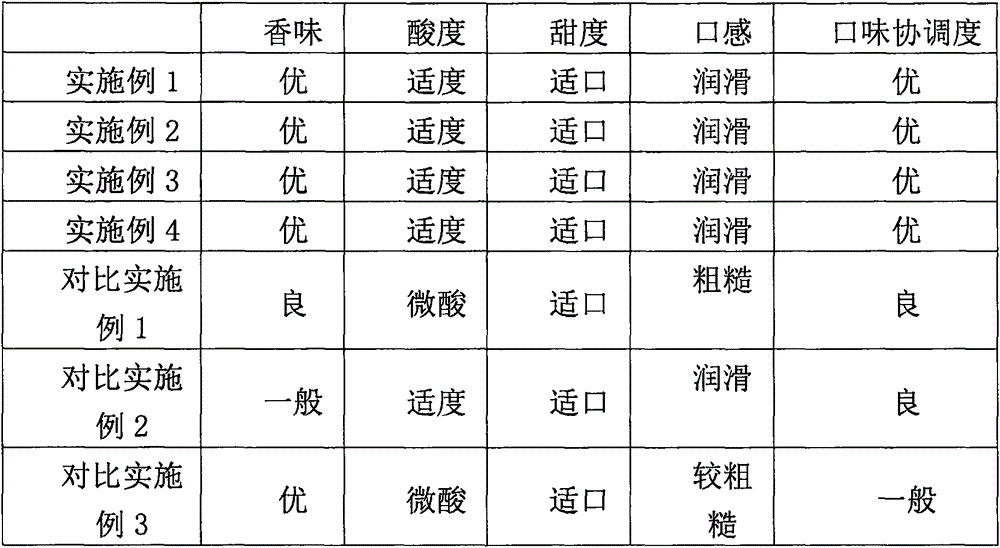

Preparation method of cane sugar-free cakes with low glycemic index, and cane sugar-free cakes

PendingCN107467132AHigh nutritional valueFull of nutritionDough treatmentBakery productsSucroseWhey protein powder

The invention discloses a preparation method of cane sugar-free cakes with a low glycemic index, and the cane sugar-free cakes. A raw material formula comprises the following components in parts by mass: 6 to 25 parts of wheat flour, 1 to 4 parts of buckwheat flour, 1 to 4 parts of oat flour, 0.5 to 2 parts of quinoa flour, 0.5 to 2 parts of mung bean powder, 0.7 to 3 parts of corn flour, 12 to 50 parts of compounded oligosaccharides, 1.5 to 6 parts of water-soluble dietary fibers, 12 to 40 parts of egg white, 7 to 26 parts of egg yolk, 2 to 8 parts of plant oil, 2 to 10 parts of whey protein powder, 10 to 38 parts of water, and 0.025-0.1 part of ammonium bicarbonate. The method utilizes no raw material containing cane sugar, and all raw materials are substitutes of the cane sugar, and the cakes are cane sugar-free products in a true sense.

Owner:美安康质量检测技术(上海)有限公司

Potato yoghourt and making method thereof

InactiveCN106465750APrevent browningNo precipitationMilk preparationOther dairy technologySweetnessSolanum tuberosum

Potato yoghourt and a making method thereof are disclosed. 40-60% of potato juice is creatively added into yoghourt, and lactobacillus bulgaricus and streptococcus thermophilus are used in cooperation for fermentation. On the basis of controlling the ratio of the materials and the making method, the potato yoghourt with rich nutrients, moderate sweetness and palatable sour taste is prepared.

Owner:SHENYANG AGRI UNIV

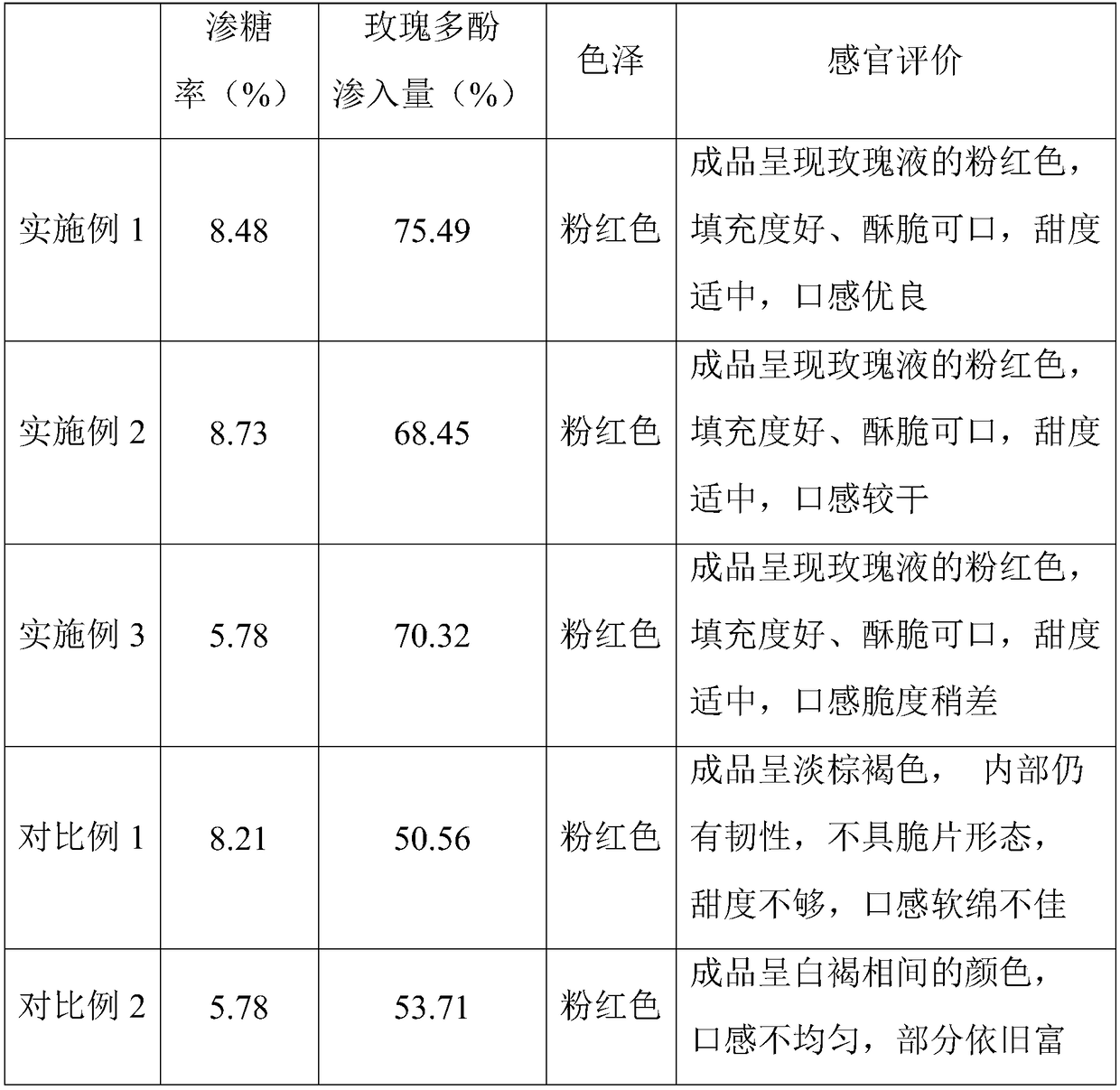

Health-care rose bergamot crisp chips and preparation method thereof

ActiveCN108991214AReduce cholesterolPromote proliferationConfectionerySweetmeatsBiotechnologyEnzymatic hydrolysis

The invention discloses health-care rose bergamot crisp chips and a preparation method thereof. The method comprises the following steps: (1) pre-selection of raw materials, i.e., cleaning; (2) slicing; (3) enzymatic hydrolysis; (4) blanching and debittering; (5) sugar immersion; and (6) dehydration and drying. The rose bergamot crisp chips prepared by the method show the pink of a rose liquid, and are good in filling degree, crisp, delicious, moderate in sweetness and excellent in mouthfeel.

Owner:SICHUAN UNIV +1

Processing technology of quick-frozen sweet potato strips

InactiveCN107692123ASoft textureResilientFood freezingFruits/vegetable preservation by freezing/coolingEscherichia coliEngineering

The invention relates to a processing technology of quick-frozen sweet potato strips. The processing technology comprises the following steps of harvesting sweet potatoes, performing saccharificationtreatment, performing cleaning, performing peeling, performing trimming, performing cutting to obtain sweet potato strips, performing soaking, performing cooking, performing baking, performing quick-freezing, performing ultraviolet sterilizing, performing vacuum packing and performing warehousing. The sweet potato strips made by the processing technology are soft in texture, have certain tenacity,are uniform in color, glossy and red, unique in mouth feel, and pure in flavor, maintain primary color of the sweet potatoes, maintain the fragrance and the flavor of the sweet potatoes, and are highin yield. Hygiene and safety are guaranteed, the quick-frozen sweet potato strips are free from any good additive, short in processing time, and low in loss of nutrient components; the quality guarantee period of the quick-frozen sweet potato strips at normal temperature is 9 months, and the quality guarantee period of the quick-frozen sweet potato strips under the refrigeration condition is 14 months. The quick-frozen sweet potato strips conform to the quality standard that the total bacterial count is smaller than or equal to 1000CFU / g, mould is smaller than or equal to 50CFU / g, the escherichia coli is smaller than or equal to 30MPN / 100g, pathogenic bacteria are not detected, and the nutrient and the flavor of the sweet potatoes can be improved, so that the requirements of consumers canbe met.

Owner:GUANGXI JIPENG INVESTMENT CO LTD

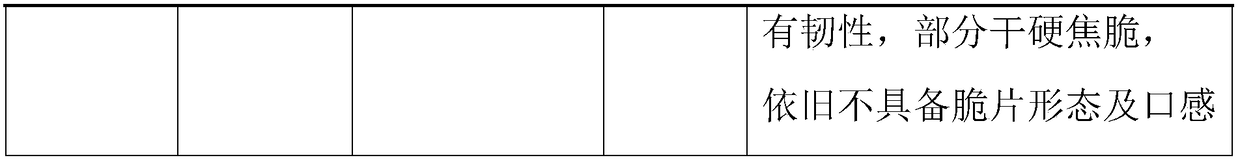

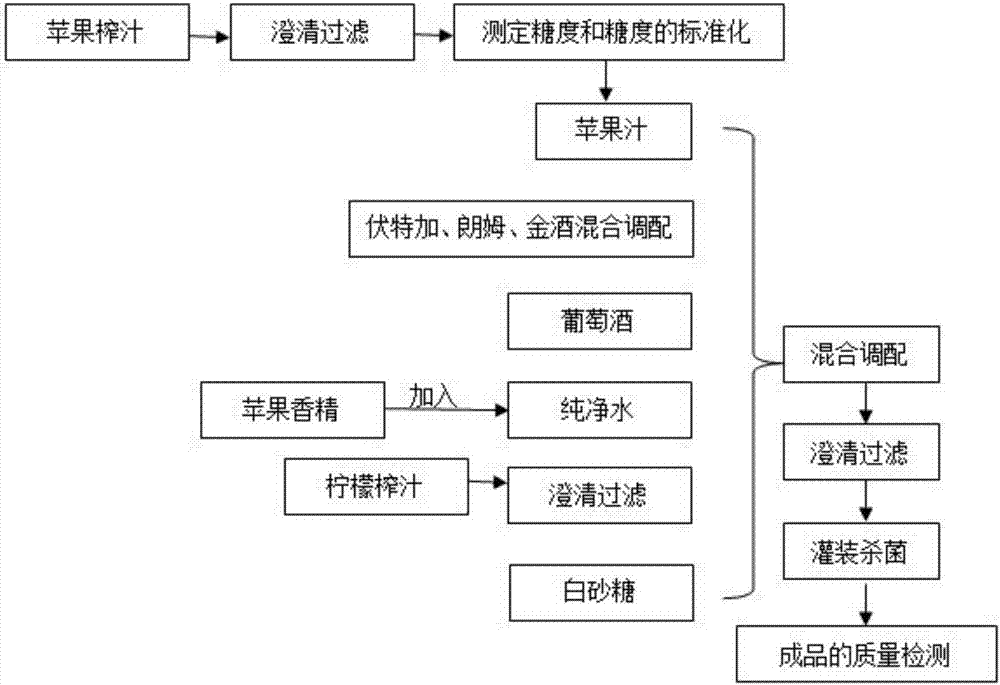

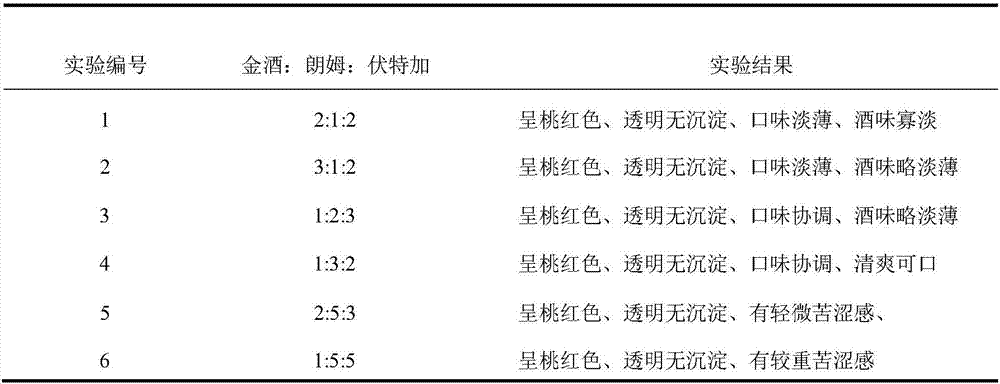

Grape and apple mixed ready-to-drink wine and preparation process thereof

InactiveCN107090395AOutstanding styleRich tasteAlcoholic beverage preparationAlcohol contentVitis vinifera

The invention discloses grape and apple mixed ready-to-drink wine and a preparation process thereof. The grape and apple mixed ready-to-drink wine is prepared from 150 to 180 parts of grape wine, 15 to 18 parts of vodka, 35 to 45 parts of rum, 22 to 28 parts of gin, 90 to 120 parts of apple juice, 28 to 35 parts of lemon juice, 500 to 1000 parts of water, 30g / L to 40g / L of white granulated sugar and 0.1g / L to 0.3g / L of apple essence. The preparation process comprises the following steps: mixing the vodka, the rum and the gin according to a ratio to form base liquor; adding the freshly pressed apple juice, the grape wine, the apple essence, the freshly pressed lemon juice, the white granulated sugar and the water into the base liquor and uniformly mixing; clarifying, filtering, filling, sterilizing and packaging a mixed solution to prepare the grape and apple mixed ready-to-drink wine. The prepared ready-to-drink wine has a cherry-red color, is transparent and glossy, has grape and apple flavors and has proper sweetness and alcohol content. The styles and characteristics of the grape wine, the gin, the rum and the vodka are fused so that the styles and characteristics of the ready-to-drink wine are more prominent. The ready-to-drink wine adopts two types of flavor raw materials, namely grapes and apples, so that a product prepared by the process has the characteristic of high nutrient value and the taste of the ready-to-drink wine is more abundant, and furthermore, the market of the ready-to-drink wine is more diversified.

Owner:ZUNYI MEDICAL UNIVERSITY

Chinese herbal tea drink and making method thereof

InactiveCN105076610AHeat-clearing and detoxifyingWith cooling blood to stop bleedingTea substituesToxicityHerb

The invention discloses Chinese herbal tea drink and a making method thereof. The making method includes the steps of 1, preparing main materials and auxiliary materials, the main materials including, by weight, 10 to 13 parts of common Lophatherum herb, 3 to 4 parts of dandelion herb, 3 to 4 parts of licorice root, 2 to 3 parts of honeysuckle flower and 2 to 3 parts of lalang grass rhizome, and the auxiliary materials including white granulated sugar, citric acid and beta-cyclodextrin; 2, extracting the main materials to obtain juice; 3, performing blending; 4, removing residue and gas; and 5, performing filling and sterilizing. The Chinese herbal tea drink has the effects of clearing heat and toxicity, cooling blood for hemostasis and the like.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Baked strip-shaped puff and preparation method thereof

InactiveCN109197955ABillet emulsification system is stableEasy to shapeDough treatmentBakery productsViscous liquidOil water

The invention discloses a baked strip-shaped puff. The baked strip-shaped puff is obtained through the following steps of: adding 5-15 parts of sugar powder and 5-15 parts of salt to 30-90 parts of water for sufficient dissolution, then mixing and heating 25-75 parts of butter and 25-75 parts of soybean oil to obtain viscous liquid, then pouring the viscous liquid into water with the sugar and thesalt, performing stirring at a low speed for 5-8 minutes, performing stirring at a medium speed and heating for 20-30 minutes, then performing homogenization treatment in a first stage at 20-30 MPa for 5-10 minutes, and performing the homogenization treatment in a second stage at 3.4-4.9 MPa for 20-30 minutes; performing treatment on an oil-water solution obtained after homogenization by adoptinga mixed semi-finished product preparation method, performing extruding into strips, and paralleling two sections of baking ingredients; and finally spraying mixed sugar syrup to the surface of semi-finished products through a high-pressure pipeline, cooling the semi-finished products on which the mixed sugar syrup is sprayed, transmitting the cooled semi-finished products to a shaping machine, and performing cutting into required size so that the baked strip-shaped puff is obtained. The baked strip-shaped puff is golden in color, fragrant, sweet and soft in taste, complete in shape, and highin security and edibility, and is deeply favored by people.

Owner:成都市彭州银裕食品有限公司

Processing technology of Radix Platycodonis and ginger juice jelly

InactiveCN105325659ALight fragranceAppropriate sweetnessConfectionerySweetmeatsBiotechnologyNutrition

The invention discloses a processing technology of Radix Platycodonis and ginger juice jelly, and belongs to the food processing field. The technology is characterized in that Radix Platycodonis, 15% of Rhizoma Alpiniae Officinarum, 55% of maltose, 6% of cerealose, 4% of starch syrup, 2.8 of modified starch, sodium alginate, sodium carbonate, agar, xanthan gum, konjaku fine powder, citric acid and a proper amount of potassium chloride are adopted as raw materials; and the processing technology comprises the following steps: selecting Radix Platycodonis, boiling, carrying out hot filtering to obtain a filtrate, mixing and stirring, adding sodium carbonate and the syrup, boiling, adding citric acid and potassium chloride, cooling, curding to form blocks, cutting the blocks, transferring to a disc, drying, and packaging. The jelly has the advantages of delicate fragrance, light taste, palatable sweetness, unique delicate fragrance flavor of Radix Platycodonis, dry and refreshing surface, soft and slightly tough mouthfeel, and unique flavor, has the efficacy of releasing and diffusing lung qi, and dispelling phlegm and pus, is suitable for being eaten by patients with coughs and much phlegm, oppression in the chest, sore throat, mute, lung carbuncle and pyocutaneous festering not ulceration, and is a low-heat and low-fat green food integrating nutrition and health values.

Owner:NANLING DENDROBIUM IND ASSOC

Low-sugar and low-fat black garlic chocolate and making method thereof

The invention discloses low-sugar and low-fat black garlic chocolate and a making method thereof, relates to chocolate and a making method thereof, and aims to provide low-fat, low-sugar and low-energy black garlic chocolate. The low-sugar and low-fat black garlic chocolate is made of black garlic sauce, black garlic powder, a cocoa mass, cocoa powder and vegetable oil. The making method includes the following steps that firstly, the black garlic sauce is added into the cocoa powder and the vegetable oil and then evenly mixed and stirred, and the mixture is poured into a mould to be formed; secondly, the cocoa mass is heated to be melted, the black garlic powder is added and evenly mixed and stirred, and then the mixture is injected into the mould in the first step in a sprayed mode; thirdly, freezing and drying are performed. The low-sugar and low-fat black garlic chocolate has the brownish-black color of common chocolate and is bright in color and luster, complete in form and low in sugar content and fat content; a chocolate coat is dense and does not shed; the strong aroma of common chocolate and the unique aroma of black garlic are coordinated, and the low-sugar and low-fat black garlic chocolate is appropriate in sweetness, crisp, fragrant, glutinous, smooth but not greasy and free of grainy mouthfeel.

Owner:DAQING BRANCH OF HEILONGJIANG ACAD OF SCI

Processing method of caramel yam bean crisp

InactiveCN105285808ACrispy and crispyAppropriate sweetnessSugar food ingredientsClimate change adaptationNutritionMouthfeel

The invention discloses a processing method of caramel yam bean crisp, and belongs to the field of food processing. The method is characterized by including utilization of yam bean, cleaning, cutting, rinse, boiling, drying, frying, sugar coating, cooling and packaging. The crisp has tawny color, crispy and sweet mouthfeel, suitable saccharinity, and specifically delicious and crisp flavor of the yam bean; is rich in protein and starch, has abundant nutrition, has effects on promoting the production of body fluid to quench thirst, clearing heat, and lowering blood pressure and lipid, is suitable to people of all ages, is a green, healthy and delicious food, and is easy to carry. The processing method is simple.

Owner:陈卫

Xylitol beverage

The invention relates to a xylitol beverage comprising the following raw materials (by weight portion): liquid xylitol 18-20, sucralose 0. 03-0. 045, lemon acid 0. 5-0. 7, natural perfume compound 0. 2-0. 25 and pure water 340-400.

Owner:张瑞发

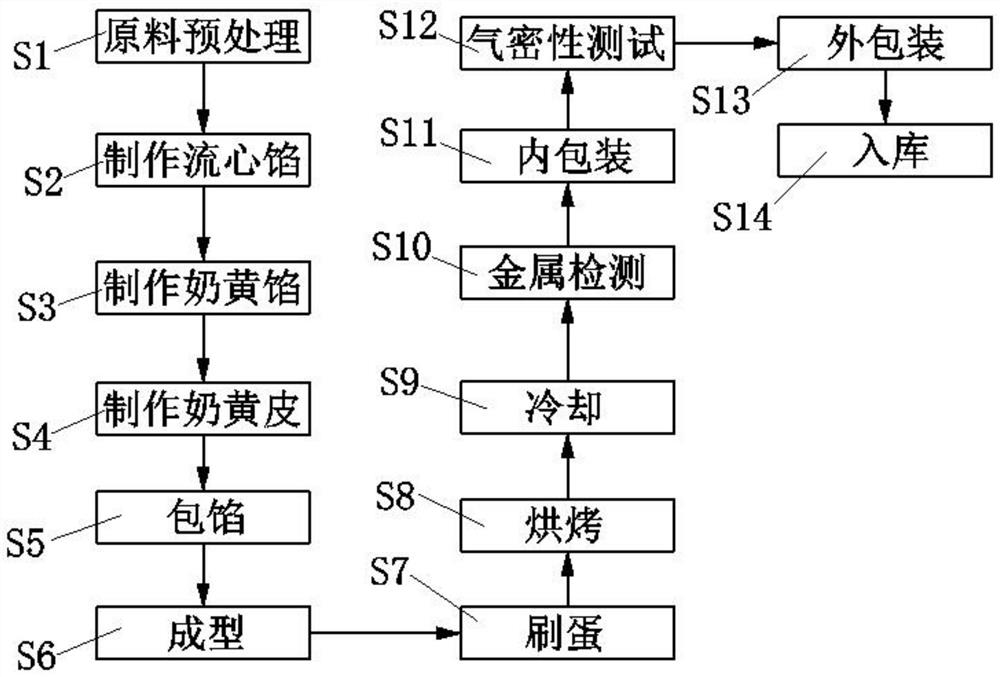

Making method for liquid stuffing custard moon cakes

The invention provides a making method for liquid stuffing custard moon cakes. The making method comprises: raw material pretreatment, liquid stuffing making, custard stuffing making, custard wrappermaking, stuffing wrapping, forming, egg liquid applying, baking, cooling, metal detecting, inner packaging, air tightness testing, outer packaging, warehousing and the like. According to the making method for the liquid stuffing custard moon cakes, formula improvement is performed on liquid stuffing, custard stuffing and custard wrappers, except for a small amount of high maltose syrup, tremella polysaccharide and the like, no edible white sugar is added, but by adding ingredients containing sugar, such as unsalted butter, fruit pulp, peanut butter, coconut milk, cinnamon powder and the like,final products can be appropriately sweet, can be sweet but not greasy, and are good for health; by improving a liquid stuffing formula and a baking process, wrapping the liquid stuffing in the custard filling and custard wrapping in a liquid form can be guaranteed; the moon cakes can taste smooth, refreshing and delicious; and the method can realize automatic production, and enhance the production efficiency of the moon cakes.

Owner:DONGGUAN HUAMEI FOOD

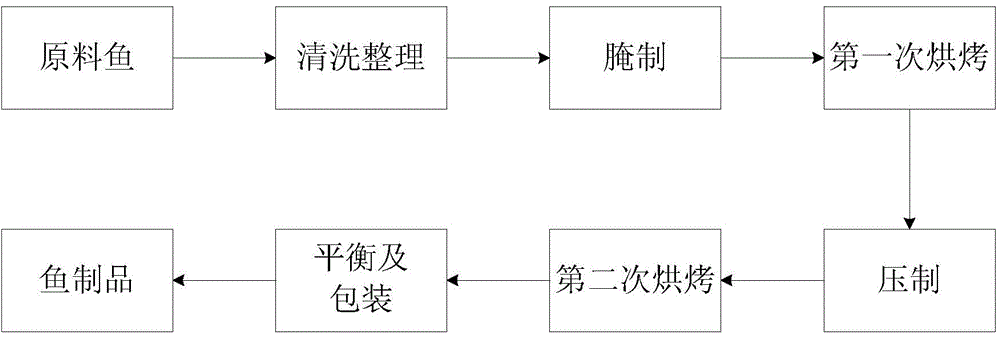

A pickling liquid for a fish product for leisure and a preparing method for the fish product for leisure

ActiveCN106031416AIncrease osmotic pressureGuaranteed shelf lifeFood preparationSalty tasteAlcohol sugars

The invention relates to a pickling liquid for a fish product for leisure and a preparing method for the fish product for leisure. The pickling liquid includes (a) 20-40 wt% of sugar alcohol, (b) 5-10 wt% of sugar, (c) 0.5-1 wt% of table salt, (d) with the balance being water and the total being 100 wt%. The method includes cleaning, finishing, pickling, roasting for the first time, roasting for the second time, performing water balancing at room temperature and packaging. The pickling liquid increases the osmotic pressure of the fish product, reduces water activity of the fish product, inhibits growth of microorganisms, and has a preservative effect. In addition, a deoxidizing preservative is put into a package bag and can remove oxygen from the package bag, thus inhibiting mould growth and oxidative deterioration of fat in the fish product. The fish product prepared by the method has characteristics of medium water activity, loose fish tissues, proper sweet taste, delicious fragrant and salty taste and a long shelf life. The shelf life at room temperature can reach 180 days or above.

Owner:SHANGHAI FOOD RES INST +1

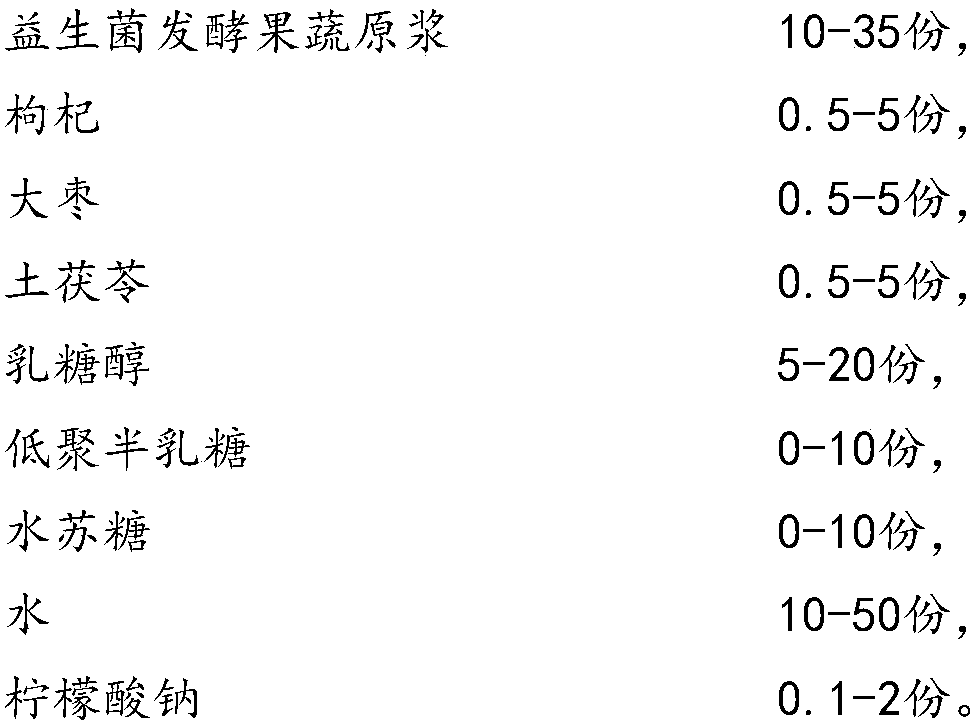

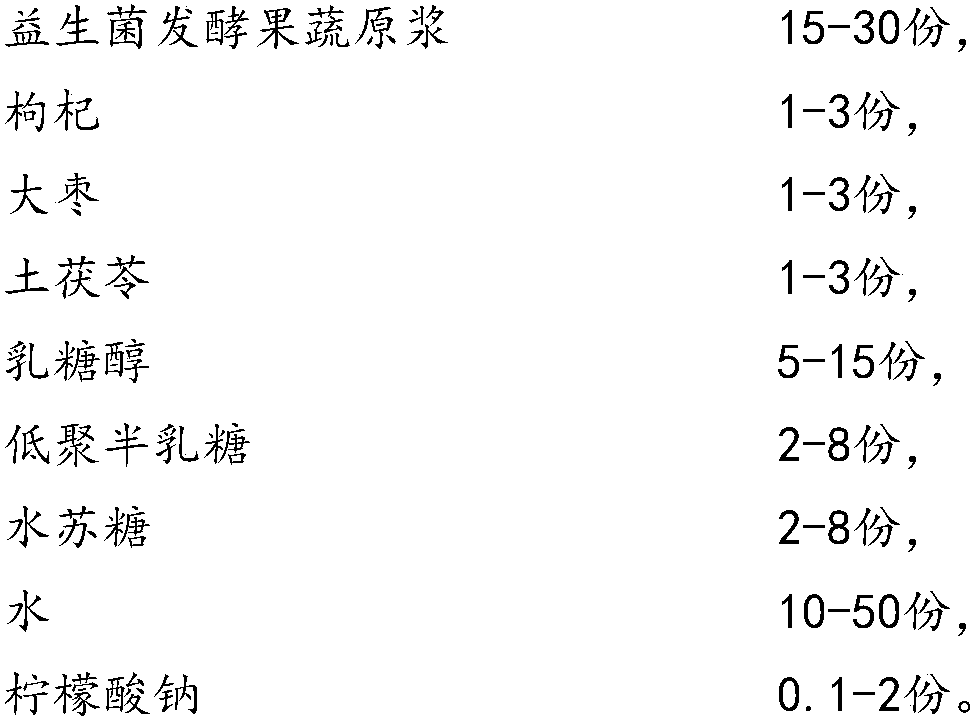

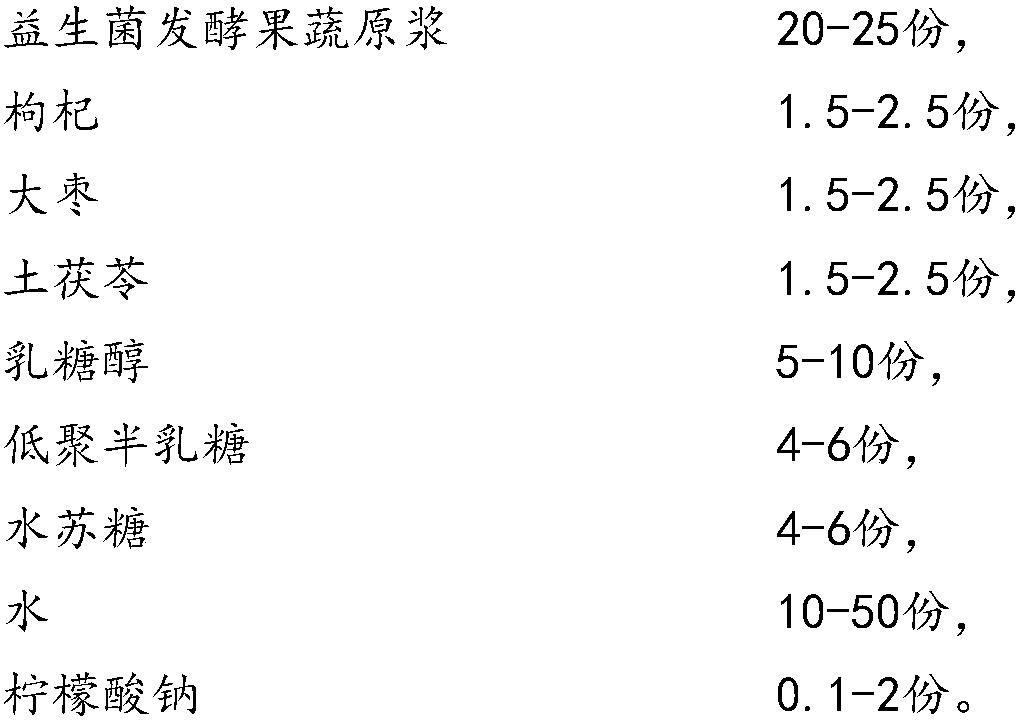

A beverage with the function of moistening the intestines and laxative

ActiveCN107495049BHas the function of digestive tract healthFor the purpose of synergyNatural extract food ingredientsFood ingredient functionsBiotechnologyGalactooligosaccharide

The invention discloses a composition, which comprises, in parts by mass: 10-35 parts of probiotic fermented fruit and vegetable puree, 0.5-5 parts of Chinese wolfberry, 0.5-5 parts of jujube, 0.5-5 parts of Smilax cocos, and 5 parts of lactitol ‑20 parts, 0‑10 parts of galactooligosaccharides, 0‑10 parts of stachyose, the composition can be used to prepare food, beverage or health care products, especially for the preparation of probiotic fermentation with laxative function Fruit and vegetable drinks. The invention also discloses a beverage comprising the above composition, water and sodium citrate and a preparation method thereof, by fermenting probiotics fruit and vegetable puree, Chinese wolfberry, jujube, Smilax tuckahoe, lactitol, galactooligosaccharides, water Threose and other substances are compounded to achieve the purpose of synergistic effect. While providing consumers with various nutrients of fermented fruits and vegetables, it can also achieve better gastrointestinal health care, especially the effect of laxative.

Owner:广东达明益派生物科技有限公司

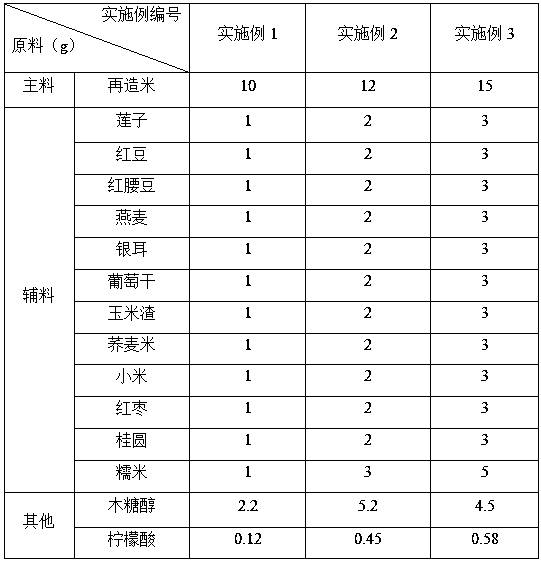

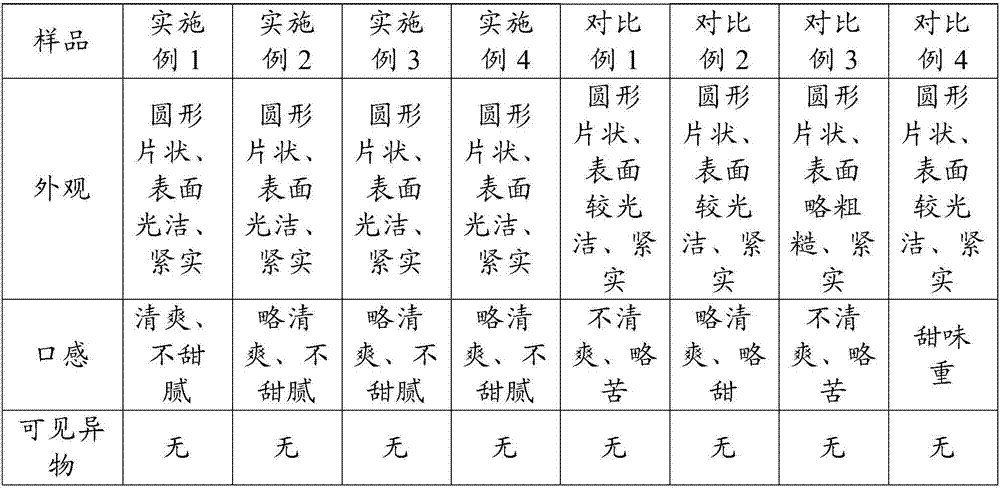

Functional nutritional porridge for anti-oxidation of body and preparation method thereof

InactiveCN108719770AGood for healthGuaranteed energyFood ingredient functionsRed beanPhysical fitness

The present invention discloses functional nutritional porridge for anti-oxidation of body. The functional nutritional porridge for the anti-oxidation comprises a main material and auxiliary materials; the main material is reconstituted rice; and the auxiliary materials comprise lotus seeds, red beans, red kidney beans, raisins, corn residues, buckwheat, millet, glutinous rice, red dates, longan,oatmeal and white fungus. The present invention also discloses a preparation method of the functional nutritional porridge. The product has an anti-oxidation effect on body, can alleviate aging, enhances physical fitness, is safe to eat and balanced in nutrients, and provides a new dietary choice for middle-aged and old friends.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Processing method for Chinese yam fruity crunchy candy piece

InactiveCN105309736ACrispy and crispyAppropriate sweetnessConfectionerySweetmeatsDietary fibresMouthfeel

The invention discloses a processing method for a Chinese-yam fruity crunchy candy piece, and belongs to the field of food processing. The processing method is characterized by including the processes of Chinese yam adopting, cleaning, slicing, rinsing, boiling, drying, frying, sugar coating, cooling and packaging. The processing method has the advantages that the Chinese-yam fruity crunchy candy piece is crispy and refreshing in taste and proper in sweetness, and has the fragrant and sweet flavor peculiar to Chinese yams; dietary fibers are rich in the product, it is facilitated of protecting gastric mucosa and assisting digestion, and the Chinese-yam fruity crunchy candy piece further has the effects of nourishing yin, nourishing the lung and reducing blood pressure and blood glucose and is environment-friendly health-caring fine food integrating great taste and nutrients.

Owner:南陵百绿汇农业科技有限公司

Processing method for dried nutritional sweet potato

InactiveCN105124479ACrispy and crispyAppropriate sweetnessFood ingredient functionsFood preparationOsteoporosisMouthfeel

The invention discloses a processing method for a dried nutritional sweet potato, belonging to the field of food processing. The method is characterized by adopting the following processing procedures: material selection; washing; peeling; steaming; drying; primary baking; flattening; shaping; heavy baking; shaping; light baking; grading; and packaging. The invention has the following beneficial effects: the dried nutritional sweet potato has fragrant and crisp taste, moderate sweetness and fragrant and sweet flavor unique to sweet potato, is favorable for improving human immunity and maintaining and regulating human functions, can prevent osteoporosis, resist ageing and prevent atherosclerosis, and is a rarely-available foodstuff with low calorie, low sugar and low fat.

Owner:彭聪

Dendrobium lozenge and preparation method thereof

ActiveCN107213351AReasonable production processAppropriate sweetnessHydroxy compound active ingredientsDigestive systemHoneysuckleToxic material

The invention belongs to the technical field of drug processing and particularly relates to a dendrobium lozenge and a preparation method thereof. The dendrobium lozenge is prepared from the following raw materials in parts by weight: 180-235 parts of dendrobium, 12-26 parts of menthol, 18-28 parts of polygonatum kingianum,17-22 parts of honeysuckle, 5-7 parts of sorbitol, 12-15 parts of chitosan, 2-6 parts of glycerin, 8-12 parts of maltodextrin and 23-40 parts of magnesium stearate. Through reasonable combination, proper sweet taste, color and luster and smell of the drug are kept, and the dendrobium lozenge has the effects of clearing away heat and toxic materials, resisting bacteria, diminishing inflammation, promoting the secretion of saliva or body fluid and smoothing the throat, and has a significant effect in treatment of sphagitis and oral ulcer; and according to the preparation method of the dendrobium lozenge, the effective components in the raw materials can be stored, and the preparation method is reasonable in production technology and suitable for industrial production.

Owner:海南诗博丽生物科技有限公司 +1

Musa nana chips and processing method thereof

InactiveCN106923262AIncrease soluteSpeed up entryFood shapingFruits/vegetable preservation by dehydrationDried bananaAllium sativum

The invention discloses a processing method of musa nana chips. The processing method comprises the following steps of step I, cutting musa nana into bar-shaped musa nana so as to obtain musa nana slices; step II, blanching the musa nana slices with water of which the temperature is 95-100 DEG C for 10-30s, then reducing the temperature of the blanched musa nana to 30-40 DEG C at the temperature reduction speed of 10-16 DEG C / min, and injecting garlic juice into the musa nana slices after temperature reduction, wherein the garlic juice is prepared through the steps of smashing garlic into garlic powder smaller than 200 meshes and adding water of which the volume is 10 times of that of the garlic powder, and the mass ratio of the musa nana slices to the garlic juice is 10 to 1; step III, freezing the musa nana slices at the temperature being minus 70 to minus 80 DEG C for 1-3h, and then macerating the frozen musa nana slices with a malt syrup solution for 3-8h, wherein the temperature of the malt syrup solution is 50-70 DEG C, and the mass concentration of the malt syrup solution is 40-60%; step IV, drying the treated musa nana slices obtained in the step III; and step V, performing puffing treatment on the dried musa nana slices so as to obtain the musa nana chips, wherein the puffing and drying conditions include that the puffing temperature is 90-100 DEG C, the puffing pressure is 0.2-0.3MPa, the stagnation time is 8-10min, the puffing number of times is 3-5, the evacuation temperature is 65-95 DEG C, and the evacuation time is 1-2h.

Owner:刘喜丹

Preparation method of sour bamboo shoots

The invention relates to the technical field of food processing, in particular to a preparation method of sour bamboo shoots. The preparation method comprises the following steps: adding 30-40 parts by weight of water into 10-15 parts by weight of fresh ginger and 5-10 parts by weight of cinnamon for decocting to prepare juice, cooling the juice, and adding 5-8 parts by weight of yellow rice winelees to the juice to prepare composite fermentation liquor, mixing the composite fermentation liquor and bamboo shoots uniformly for one-stage fermentation for the fermentation time of 4-5 days; and inoculating bifidobacteria, lactococcus lactis and lactobacillus plantarum into the bamboo shoots which are subjected to the one-stage fermentation to carry out second-stage fermentation for 3-5 days to obtain the sour bamboo shoots. According to the method disclosed by the invention, the fresh ginger, the cinnamon and the yellow rice wine lees are mixed and cooperatively fermented to ferment the bamboo shoots, so that the generation of nitrite in pickled vegetables can be inhibited, rapid propagation of lactic acid bacteria in the second-stage fermentation process can also be promoted, the whole production period is only 7-10 days, and the content of the nitrite in the sour bamboo shoots is lower than that of the sour bamboo shoots prepared in a traditional manner.

Owner:福建峨嵋祥鑫生态笋竹食品有限公司

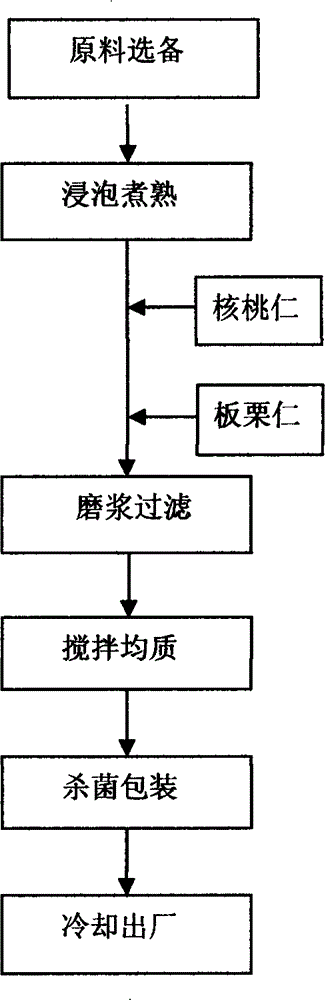

A longevity food beverage with pure vegetable proteins and a preparation method thereof

InactiveCN104544418AHigh medicinal valueGreat tasteFood ingredient functionsMilk substitutesBiotechnologyAnimal science

The present invention discloses a longevity food beverage with pure vegetable proteins and a preparation method thereof. The beverage uses the specialities of the longevity village including semen cannabis, corn, English walnut seed and chestnut kernel as main raw materials. The preparation method includes the following steps: selecting and preparing the raw materials, soaking and cooking the raw materials, grinding and filtrating the raw materials, stirring and homogenizing the raw materials, sterilizing, packaging and cooling the mixture so that the beverage can leave the factory. By using in conjunction with several kinds of the raw materials and being complemented with sugar, the beverage has rich and comprehensive in nutrition, milky yellow in color and lustre, fine and smooth in mouthfeel, palatable in sweetness. The beverage is good for all ages, and has effects in moisturizing dryness syndrome, smoothing intestine, treating stranguria, invigorating blood circulation, whetting appetite by long term drinking. The beverage can reduce the incidence of cardiovascular disease and cancer, and is a health-care longevity food beverage that can be eaten as medicine or food. The beverage is simple in formula, easy in preparation, low in costs and abundant in the raw materials, and is suitable for micro, small and medium-sized manufacturers to produce.

Owner:覃美英

Natural black bean health food

InactiveCN108013366AUniform colorAppropriate sweetnessFood ingredient functionsFreeze-dryingAstaxanthin

Belonging to the field of food processing, the invention discloses a natural black bean health food. The natural black bean health food is prepared from the following raw materials by weight: 20-40 parts of black bean powder, 15-30 parts of aloe vera whole leaf freeze-dried powder, 20-30 parts of astaxanthin, 10-30 parts of water-soluble pearl powder and 10-30 parts of sugar. The natural black bean health food provided by the invention has the characteristics of reasonable formula, common main raw materials, moderate price, and simple and scientific making process, the produced product has very rich nutrition, has the functions of defying aging, maintaining beauty and keeping young, removing toxin and the like, can be used directly or dissolved in water for drinking, and is a economical product with health care and nutritious functions.

Owner:威海御膳坊生物科技有限公司

Processing method of silver and novel crisp snack

InactiveCN107594054AIncrease productionIncrease the areaConfectionerySweetmeatsChipped potatoesSweetness

The present invention discloses a processing method of silver and novel crisp snack. Potatoes or sweet potatoes are subjected to a material selecting, washing, cooking and peeling are conducted, afterthe materials are minced, the minced materials, flour, milk powder, fermentation powder, potato paste or sweet potato paste and starch are put into a dough mixer to be mixed evenly, the mixture is oil-fried and shaped, the shaped semi-finished products are air-dried, white granulated sugar is put into a sugar boiling pot, water is added, the white granulated sugar is heated to be melted until thewhite granulated sugar is completely melted, maltose is added, the sugar is heated using low heat and continuously stirred until a sugar solution can pull out filaments, the oil-fried and air-dried potato chips are poured into the pot with the boiled sugar solution, a pot turner is used to conduct a rapid stirring from top to down and left to right when the sugar solution is still hot to enable the potato chips to be evenly stick with a layer of the sugar solution around, when the potato chips are still hot, the potato chips are poured into molds, the potato chips are spread flatly and compressed moderately, sesame seeds and green and red silk are sprinkled, and when the materials are slightly cooled, the materials are cut into blocks. The silver and novel crisp snack is simple in preparation method, processed by using the potatoes, sucrose and flour as raw materials, attractive in appearances, fragrant and crisp in taste, and moderate in sweetness.

Owner:李淑存

Crunchy white radish strips and processing method thereof

InactiveCN107048257AImprove crispnessIncrease soluteFood freezingFood preservationMaltose SyrupFood science

The invention discloses a method for processing crunchy white radish strips. The method comprises the following steps of: step 1, cutting a white radish into strips with a length of 3-5cm and a thickness of 0.5-1cm to obtain white radish strips; step 2, blanching the white radish strips at a temperature of 95-100 DEG C for 10-30s, and then cooling the blanched white radish strips to 30-40 DEG C at a cooling rate of 10-16 DEG C / min; step 3, freezing the cooled white radish strips at a temperature of 70-80 DEG C for 1-3h, and then immersing the frozen white radish strips in a maltose syrup solution with a mass concentration of 40-60% at a temperature of 50-70 DEG C for 3-8h; step 4, drying the white radish strips treated in step 3; and step 5, puffing the dried white radish strips to obtain the crunchy white radish strips, wherein the conditions for puffing the dried white radish strips are that the puffing temperature is 90-100 DEG C, the puffing pressure is 0.2-0.3 MPa, the dead time is 8-10 min, the puffing times is 3-5 times, the evacuation temperature is 65-95 DEG C, and the evacuation time is 1-2h.

Owner:刘喜丹

Processing method of diosorea cirrhosa caramel pieces

InactiveCN106035951ACrispy and crispyAppropriate sweetnessConfectionerySweetmeatsWater contentToxic material

The invention discloses a processing method of diosorea cirrhosa caramel pieces and belongs to the field of food processing. The processing method is characterized by including: selecting diosorea cirrhosa, cleaning, slicing, rinsing, cooking, drying, frying, coating with sugar and cooling and packaging. The diosorea cirrhosa caramel pieces processed by the method is fragrant and crispy in taste and appropriate in sweetness and has the special sweet and fragrant flavor of diosorea cirrhosa; the diosorea cirrhosa caramel pieces can improve the immune function of human bodies and promote bone development, have effects of clearing away heat and toxic materials and stopping bleeding and activating blood, is economic green nutritional food suitable for people of all ages, and is low in water content and suitable for being stored for a long time.

Owner:吴蓓蓓

Method for processing instant dried sweet potato

The invention provides a method for processing an instant dried sweet potato, which comprises the following steps of: carrying out storage and saccharification pretreatment on a fresh sweet potato; cleaning the sweet potato, removing the peel of the fresh sweet potato and cutting the sweet potato into strips; blanching for 15-30 seconds; leaching; adding 1-3 percent by mass of honey; steaming for30-45 minutes in steam; drying to the water content of 32-36 percent at 60-70 DEG C in microwave vacuum; adding 0.2-0.4 percent by mass of mountain naphthalene oil; steaming for 15-30 minutes in steam; drying to the water content of 14-18 percent at 50-60 DEG C in microwave vacuum; storing and dampening to the water content of 20-24 percent at 4-8 DEG C in a refrigeration house; and carrying out microwave sterilization at 30-40 DEG C for 3-6 minutes; and packaging in vacuum. By adopting the processing method of the invention, the produced instant dried sweet potato has flexible texture and certain toughness and can be chewed by all people regardless of age and sex; the product has uniform color, presents red gloss and has the potato flavor deserved by the variety, palatable sweetness, no any food additive, short vacuum microwave drying time and less loss of nutrition components; the product has the normal temperature quality guarantee period for 9 months and the refrigeration quality guarantee period for 12 months; the quality standard of the product meets the following condition: the total bacterial amount is not more than 1,000 CFU / g, the mould is not more than 50 CFU / G, the escherichia coli is not more than 30 MPN / 100g, and pathogenic bacteria are not detected; in addition, the energy consumed for producing the instant dried sweet potato is reduced by more than 30 percent compared with the energy consumed for producing the instant dried sweet potato by hot air drying.

Owner:ZHEJIANG UNIV OF TECH

Purple cabbage fruit tea and preparing method thereof

The invention discloses purple cabbage fruit tea and a preparing method thereof. The purple cabbage fruit tea is prepared from, by mass, 10-25% of purple cabbage, 0.2-1.5% of citric acid, 1.5-2.3% of CMC glue, 5-13% of white granulated sugar, 30-50% of syrup, 1-5% of honey and 20-30% of distilled water. The preparing method includes the following concrete steps that 1, purple cabbage is shredded and blanched; 2, a certain amount of distilled water is weighed and added into a container, and then citric acid is added and stirred to be dissolved; 3, CMC glue is weighed, added into the container and stirred uniformly; 4, white granulated sugar, syrup and honey are weighed, sequentially added into the container and stirred uniformly, and then the purple cabbage is added; 5, the solution is bottled, the bottle is capped and put into boiling water to be boiled for 20 min, the glass bottle is taken out and cooled to room temperature to prepare the purple cabbage fruit tea. The prepared purple cabbage fruit tea contains a great number of vitamins, has the effect of body building and can enhance human vigor if people drink the fruit tea often.

Owner:XUZHOU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com