Method for processing instant dried sweet potato

A processing method and technology of drying sweet potatoes, applied in food preparation, food science, application, etc., can solve the problems of unsterilized products, affecting consumers, poor product toughness, etc., and achieve good color-aroma-taste, soft texture, The effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

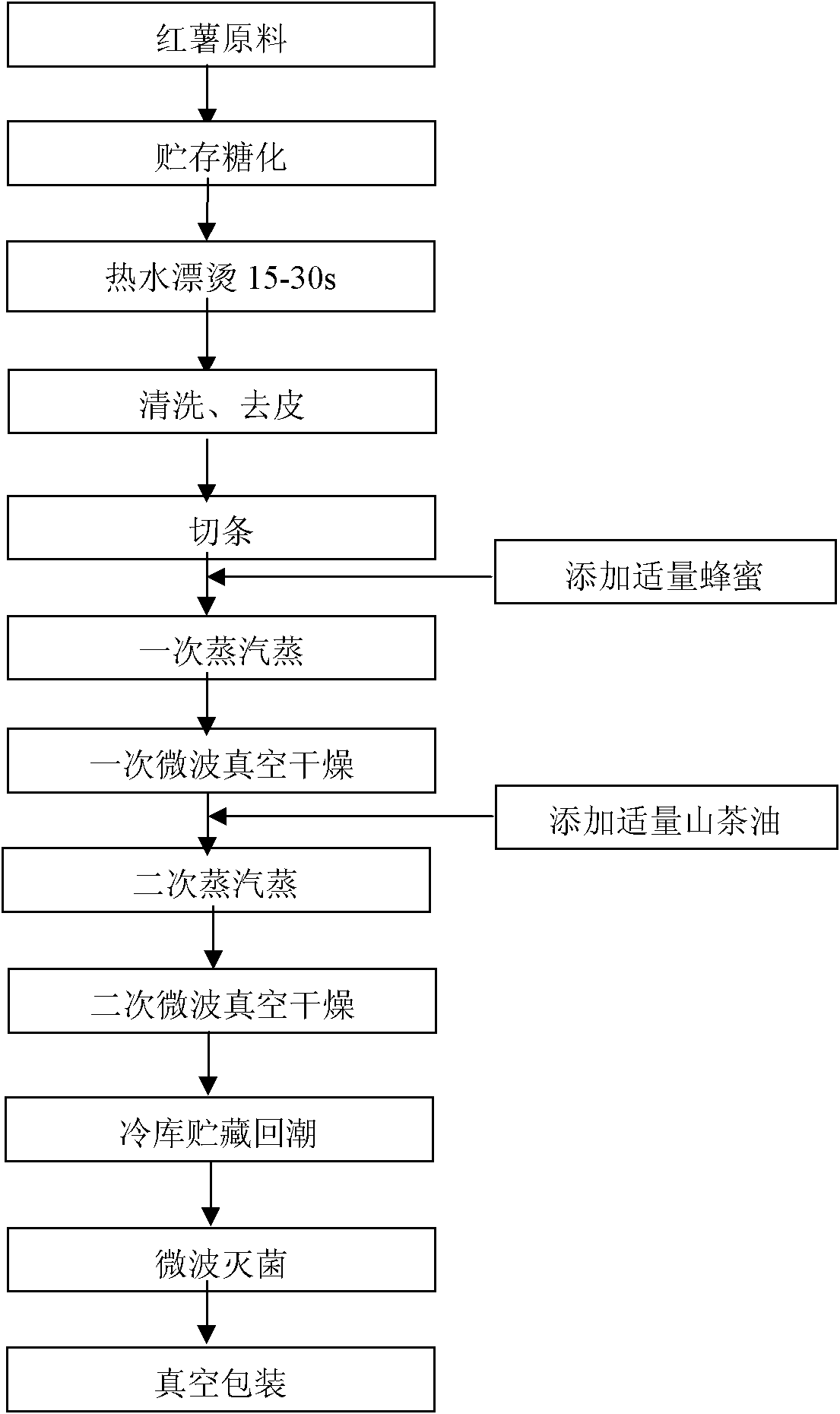

Image

Examples

Embodiment 1

[0032] 1. Selection of raw materials: Sweet potatoes are required to be harvested before the frost period. Choose fresh potatoes with smooth and tender skin, no wormholes, no disease spots, no tatters, no peculiar smell, and 100-500 grams in size as raw materials;

[0033]2. Storage and saccharification treatment: put fresh potato pieces into ventilated plastic baskets, stack them on top of each other in a cool and ventilated place indoors, store at a room temperature of 12°C, and store for saccharification for 15 days.

[0034] 3. Cleaning: Wash the soil on the surface of fresh potatoes with clean water, and a fruit and vegetable cleaning machine can be used.

[0035] 4. Peeling: manual or mechanical peeling.

[0036] 5. Cut into strips: Cut the cleaned sweet potatoes into long strips of about 2.5cm×2.5cm×5cm by hand or mechanically.

[0037] 6. Blanching: Blanch in hot water at 80°C for about 30 seconds to inhibit the enzyme activity of sweet potatoes, and drain after blanc...

Embodiment 2

[0049] Process flow see attached figure 1 , see embodiment 1 for the detailed process. Fresh potatoes→storage at 15°C and saccharification for 10 days→cleaning→peeling→cutting into strips→blanching in hot water at 85°C for 20s→draining→adding honey with 1% of the dry mass of sweet potatoes→steaming for 30 minutes at a time→microwave vacuum drying at 60°C once ( Simultaneously sterilized) to a moisture content of 35% → add camellia oil of about 0.3% of the dry mass of sweet potatoes → steam for a second time for 30 minutes → secondary microwave vacuum drying at 50°C (simultaneously sterilized) to a moisture content of 18% → store in a cold storage at 4°C Moisturize for 5 days until the moisture content is 24% → Microwave sterilization at 30°C for 3 minutes → Vacuum small packaging.

[0050] The resulting dried sweet potato product is brownish-red, shiny, has the proper potato flavor of this variety, and has a pleasant sweetness. After inspection, the total number of bacteria i...

Embodiment 3

[0052] Process flow see attached figure 1 , see embodiment 1 for the detailed process. Fresh potatoes→storage at 15°C for saccharification for 10 days→cleaning→peeling→cutting into strips→blanching in hot water at 80°C for 30s→draining→adding honey with 3% of the dry mass of sweet potatoes→steaming for 45 minutes at a time→microwave vacuum drying at 70°C once ( Simultaneously sterilized) to a moisture content of 35% → add camellia oil of about 0.2% of the dry mass of sweet potatoes → steam for a second time for 15 minutes → second microwave vacuum drying at 60°C (simultaneously sterilized) to a moisture content of 15% → store in a cold storage at 4°C Rehydrate for 3 days to moisture content of 20% → microwave sterilization at 30°C for 6 minutes → vacuum small packaging.

[0053] The resulting dried sweet potato product is brownish red, shiny, has the proper sweet potato flavor of this variety, and has a pleasant sweetness. After inspection, the total number of bacteria in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com