Machine vision-based flexible roll forming device and calibration method

A technology of machine vision and calibration method, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of long processing and forming time, poor adaptability, low efficiency, etc., and achieve high automation, high efficiency, and error compensation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

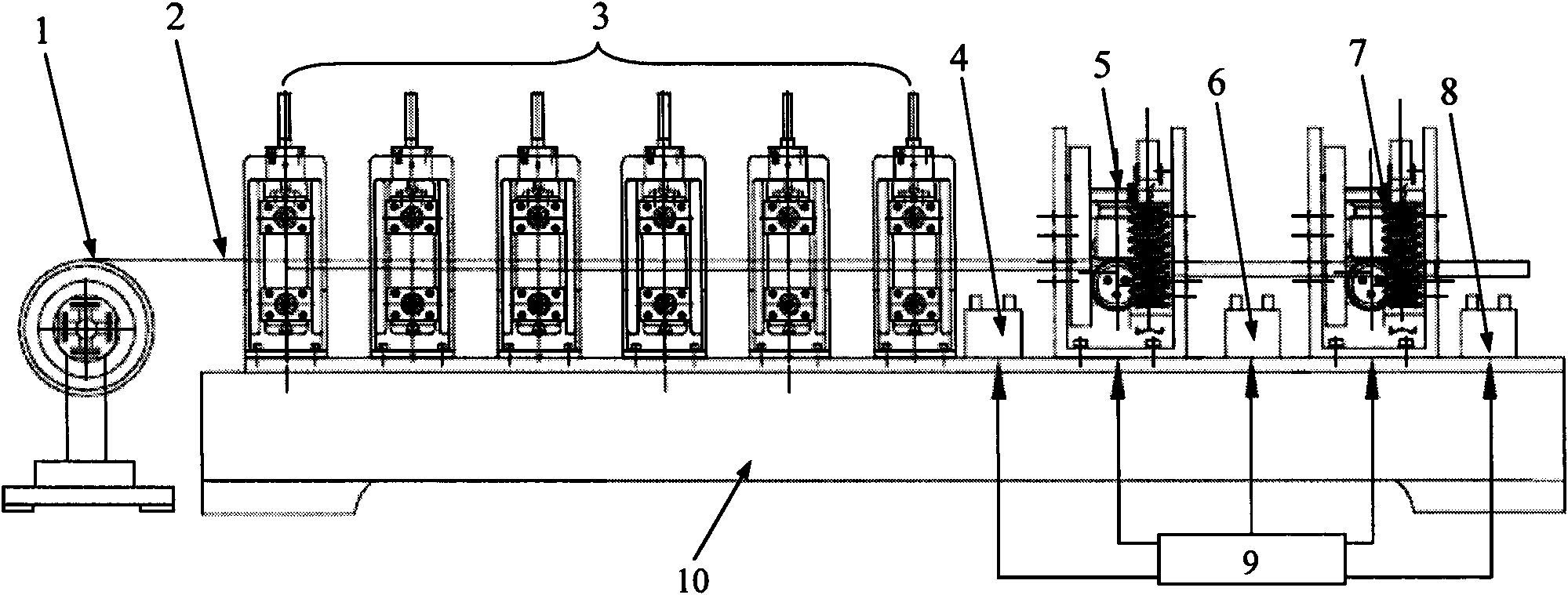

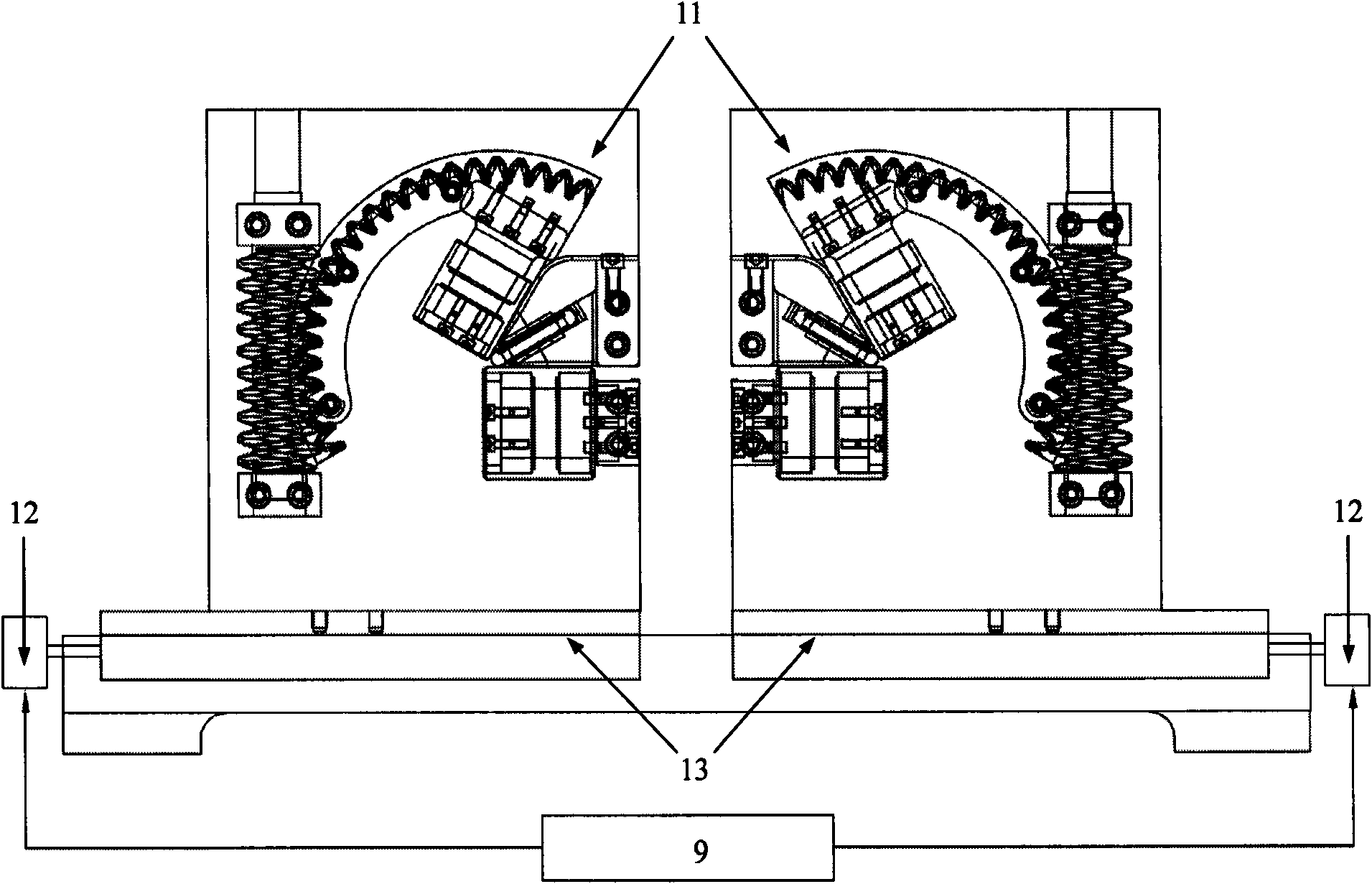

Method used

Image

Examples

Embodiment

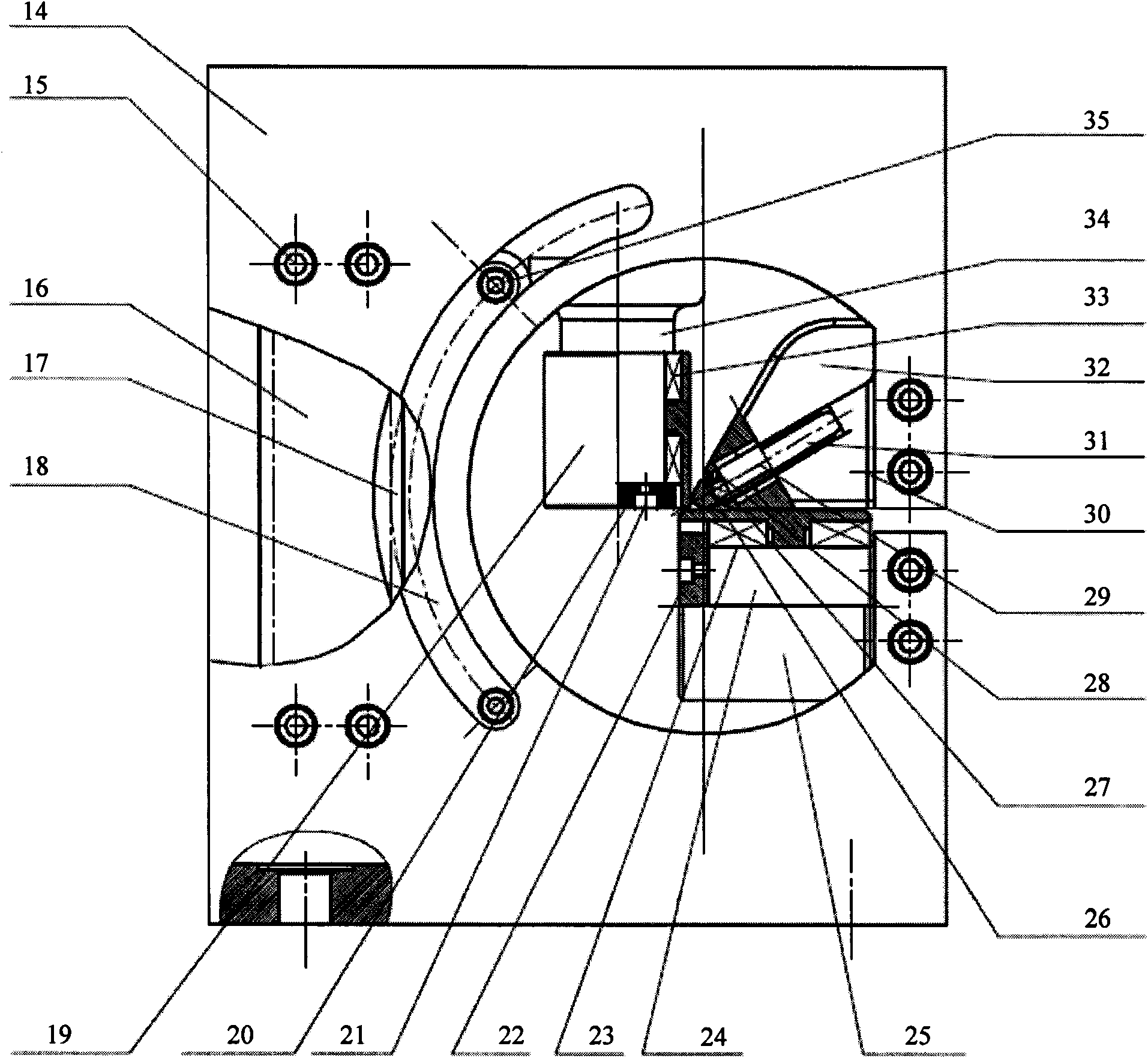

[0033] At room temperature, three frames are used to form square pieces, and the forming angles of each frame are 30°, 60°, and 90° in turn, and the distance between frames is 250mm. The forming material is Dogal 800DP, the section is a symmetrical U-shaped section, the length of the plate is 600mm, the width is 72.32mm, the thickness is 0.8mm, and the forming corner radius R is 2mm. The forming speed was set at 5 m / s. Such as Figure 6 41 in shows the ideal shape of the product.

[0034] After the plate comes out of the roll, the plate will rebound, and the rebound angle detected by the first visual inspection device is 2.11°, such as Figure 6 39. Then the detected angle signal is transmitted to the computer control system, and the computer determines the calibrated passes and cornering angles after calculation. This can be calibrated once. The control device controls the motor to drive the worm to rotate, and then drives the worm wheel and the cage to slide along the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com