Method for producing seamless pipe

A manufacturing method and technology for seamless pipes, which are applied in the directions of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of uniform sintering and shortening of the service life of the plug.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

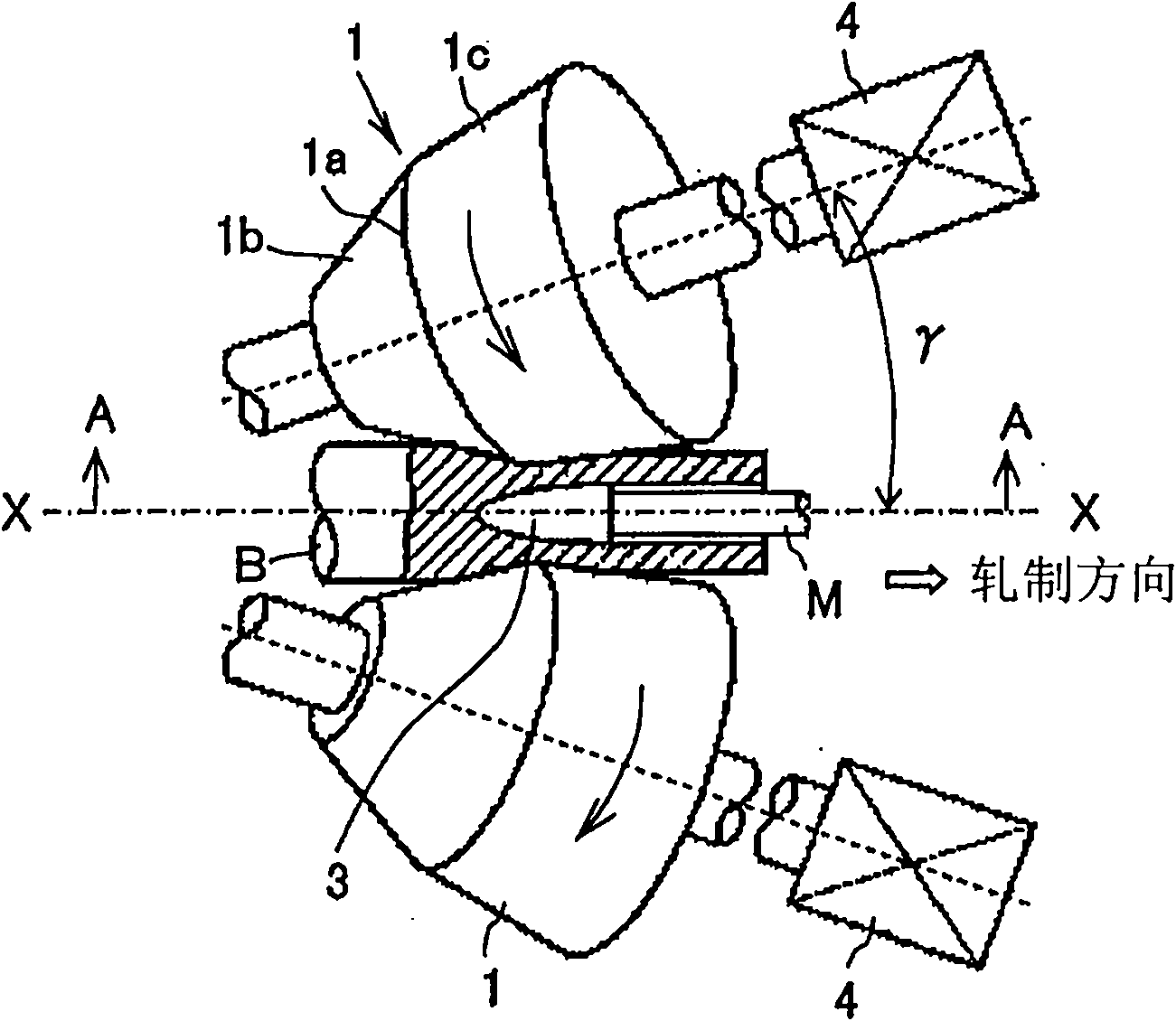

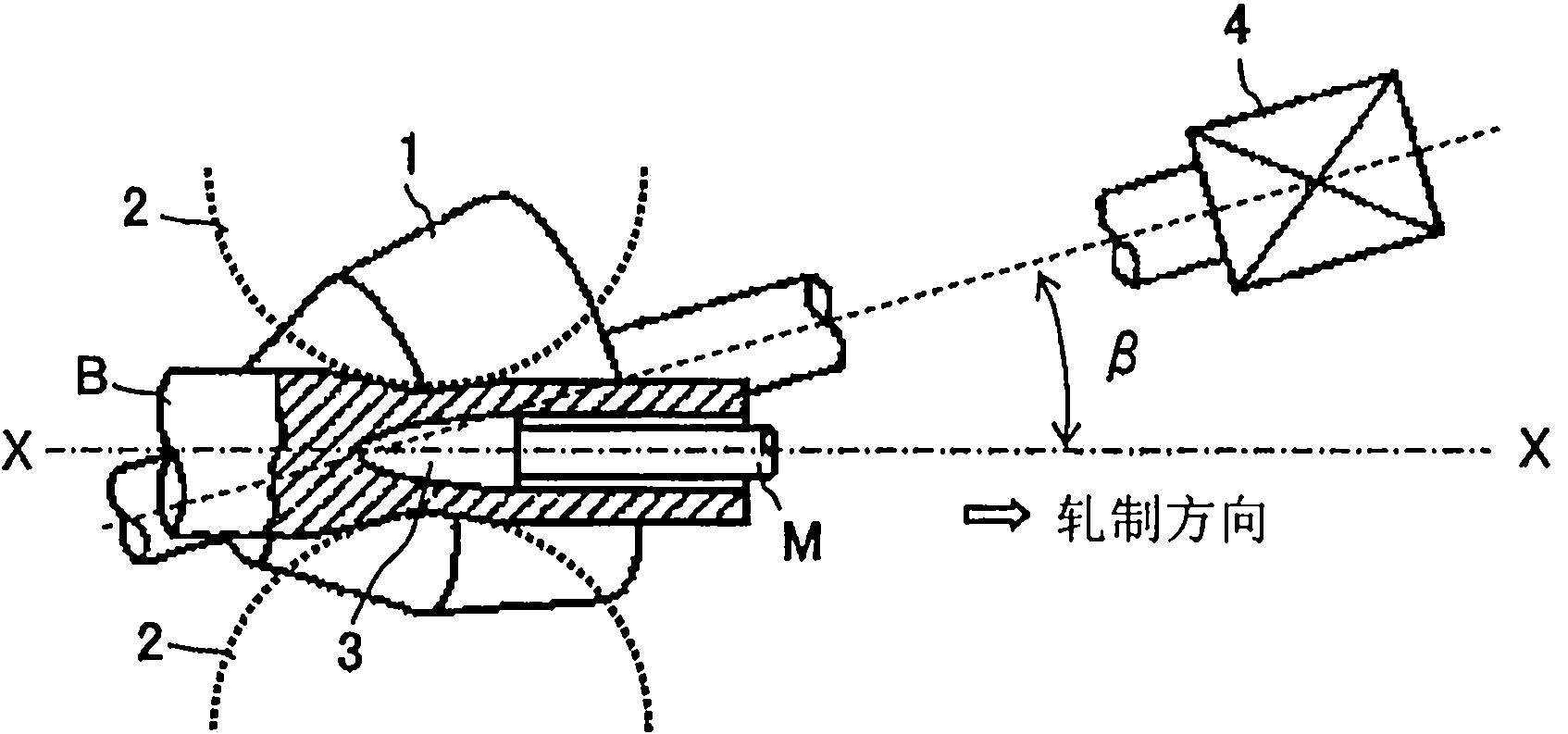

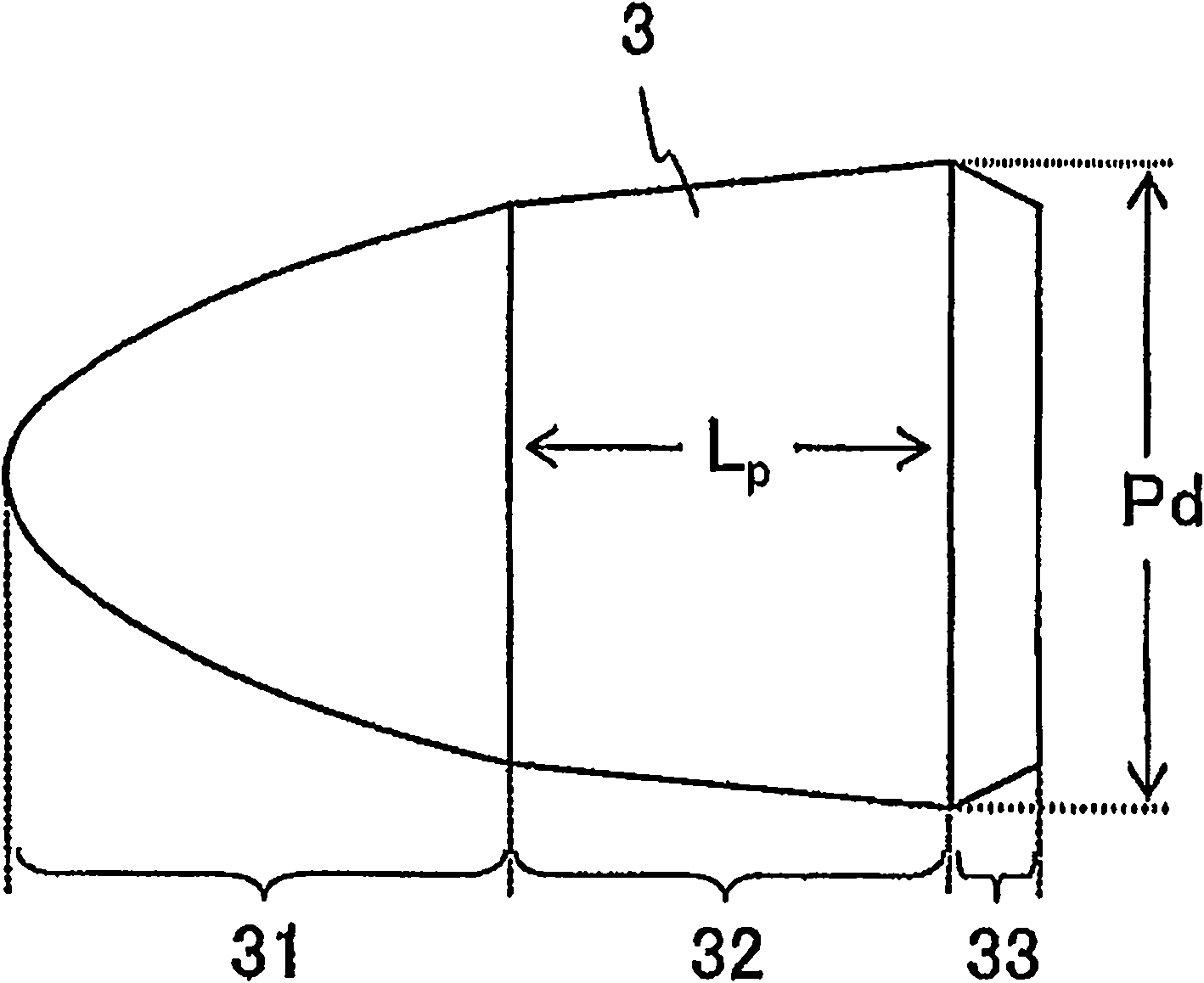

[0102] For the steel types having the chemical compositions shown in Table 1, a φ70 round billet was cut from the center portion of a φ225 round billet produced by continuous casting by billet rolling as a test material. As for the guide part, use disc-shaped rolls, change the shape of the main roll and the shape of the plug to perform piercing and rolling under the manufacturing conditions shown in Table 2 or Table 3, and measure the roughness of the inner surface of the hollow shell (defined in the JIS-0601 standard maximum height Rz).

[0103] [Table 1]

[0104] Table 1

[0105]

[0106] [Table 2]

[0107] Table 2

[0108] heating temperature

1180℃~1240℃

Tilt angle β

7°~16°

φ350~φ410mm

Main roll exit face angle θ r

3°~5.5°

Roll diameter ratio D 2 / D 1

0.9~1.3

Δθ=θ p -θ r

-0.25°~1.0°

Hollow tube outer diameter

70.0~75.0mm

Hollow tube blan...

Embodiment 2

[0118] After the continuous casting material having the chemical composition shown in Table 1 is made into a round billet of φ191 by billet rolling, 100 round billets with an outer diameter of φ73 , wall thickness t5.51 seamless steel pipe, and its inner surface characteristics were investigated. The results are shown in Table 5.

[0119] [Table 4]

[0120] Table 4

[0121] heating temperature

1240℃

Tilt angle β

6°~16°

Main roll chisel diameter D 1

φ1400mm

[0122] Main roll exit face angle θ r

3°~4°

Roll diameter ratio D 2 / D 1

1.05~1.15

Δθ=θ p -θ r

-1.5°~1.25°

Head leveling number R n

0.8~3.5

[0123] [table 5]

[0124] table 5

[0125]

[0126] However, the meanings of A to E in the above table are as follows.

[0127] A: Calculated value of "Rn-(-0.37×Δθ+1.47)".

[0128] B: Calculated value of "Rn-(-0.24×Δθ+1.73)".

[0129] C: Calculated value of "0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com