Method for reducing rough rolling wrinkles of rods and wires

A technology of rough rolling of rods and wires, which is applied in the direction of instruments, electrical digital data processing, computer-aided design, etc., can solve the problems of uncertainty, restriction of product quality, time-consuming and labor-consuming, etc., to reduce the damage rate and improve the surface quality , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1. The test material is welding wire steel ER70S-6, and the compression test is carried out on a Gleeble 3500 thermal simulation testing machine. The specific steps are as follows: first, heat to 1200°C for 3 minutes at a heating rate of 10°C / s to complete austenitization, then at a cooling rate of 10°C / s to the deformation temperature and hold for 1min. The deformation temperatures are 900°C and 1000°C respectively. ℃, 1100℃, 1200℃; the strain rate is 0.01S respectively -1 , 0.1S -1 , 1S -1 , 10S -1 . Therefore, the true stress-true strain curves of the material at different temperatures and strain rates are obtained, and the Johnson-Cook constitutive model is used to fit it, and finally its constitutive parameters are determined, which can be expressed as:

[0049]

[0050] in, is the equivalent strain rate; is the equivalent stress; T is the temperature;

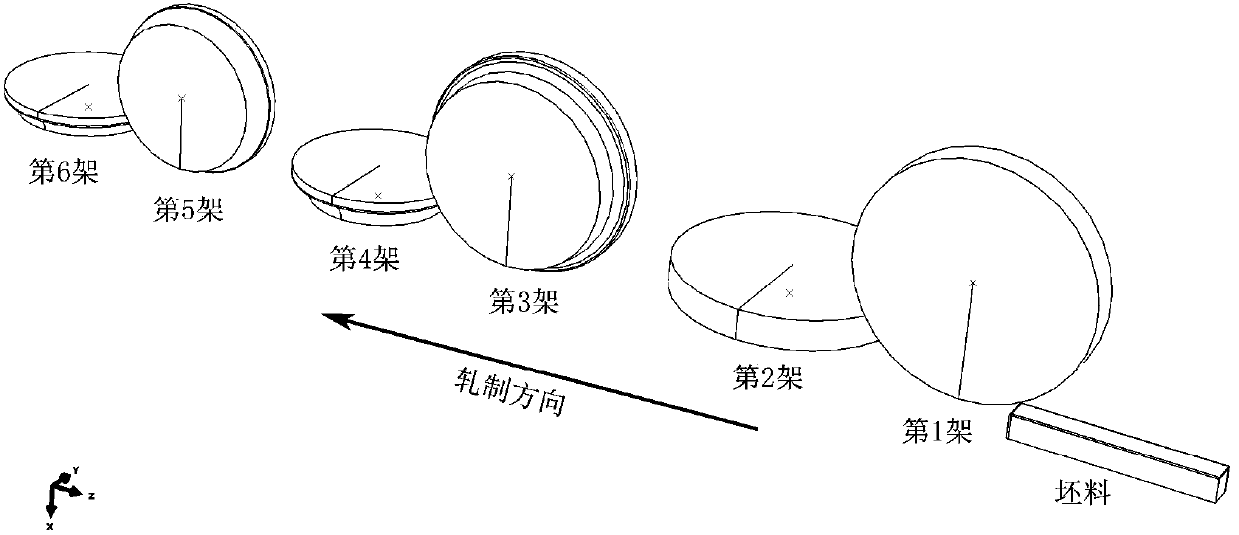

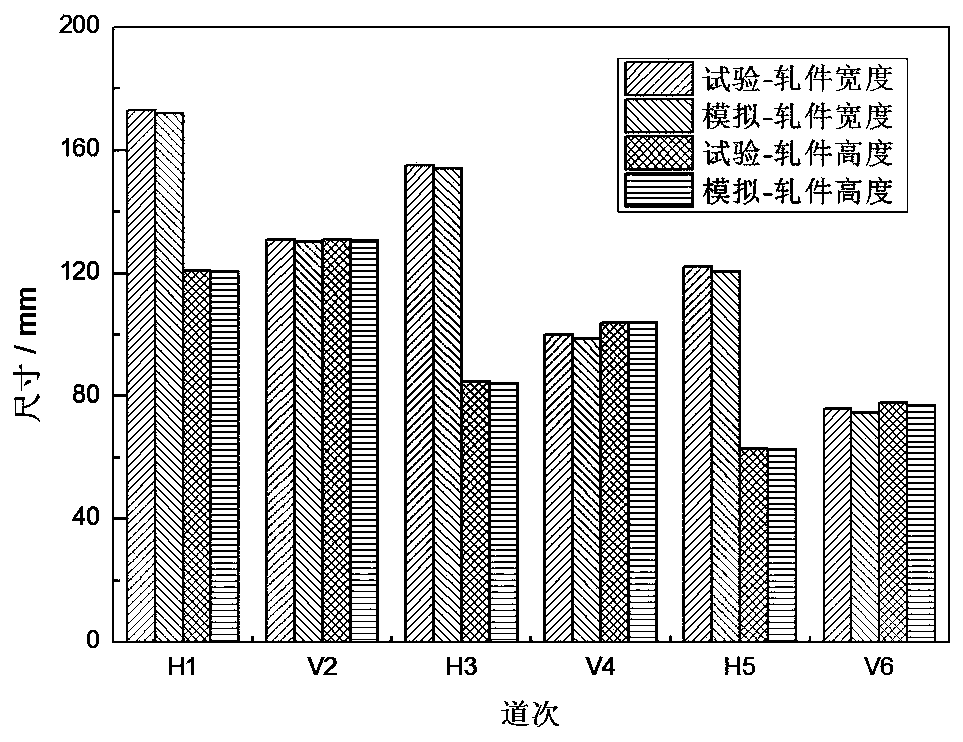

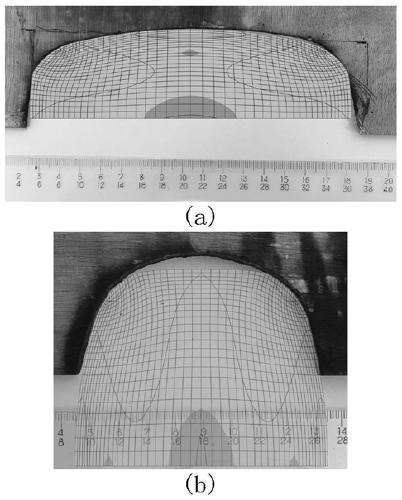

[0051] 2. Use Abaqus / Explicit finite element software to establish a three-dimensional thermal-mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com