Ferritic stainless steel with excellent wrinkling characteristics and surface quality and method for producing the same

A technology of stainless steel and ferrite, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., to achieve the effect of excellent wrinkling characteristics, high r value, and excellent surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] Hereinafter, embodiments of the present disclosure will be described in detail with reference to the accompanying drawings. These embodiments are provided to fully convey the concept of the disclosure to those of ordinary skill in the art. This disclosure may, however, be embodied in many different forms and should not be construed as limited to the exemplary embodiments set forth herein. In the drawings, in order to clearly describe the present disclosure, parts irrelevant to the description are omitted, and the size of elements may be exaggerated for clarity.

[0040] The ferritic stainless steel having excellent wrinkling characteristics and excellent surface quality according to an embodiment of the present disclosure contains 0.005% to 0.1% of carbon (C), 0.01% to 2.0% of silicon (Si ), 0.01% to 1.5% manganese (Mn), 0.05% or less phosphorus (P), 0.005% or less sulfur (S), 10% to 30% chromium (Cr), 0.005% to 0.1 % nitrogen (N), 0.005% to 0.2% aluminum (Al), the re...

Embodiment

[0083] Molten steel having the composition shown in Table 1 was continuously cast to prepare slabs, and the slabs were hot rolled by reheating. Then, the hot-rolled steel sheet with an initial thickness of 3 mm to 7 mm is cold-rolled once before thermal annealing.

[0084] Table 1

[0085]

[0086] The primary cold rolling is performed at a reduction ratio of 20% to 50% using conventional cold rolling or asymmetric cold rolling. After thermal annealing and pickling of the primary cold-rolled steel sheets, secondary cold rolling was performed at a reduction ratio of 50% to 85%, followed by cold annealing and pickling to prepare samples.

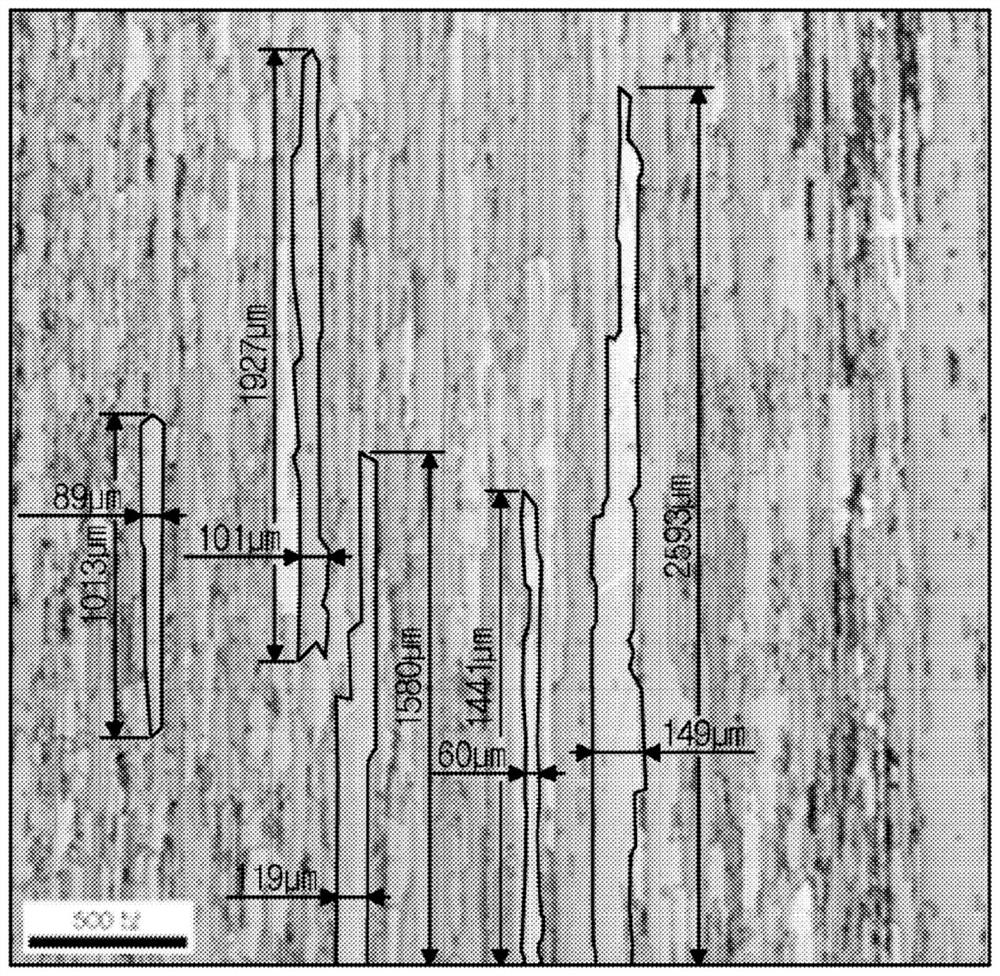

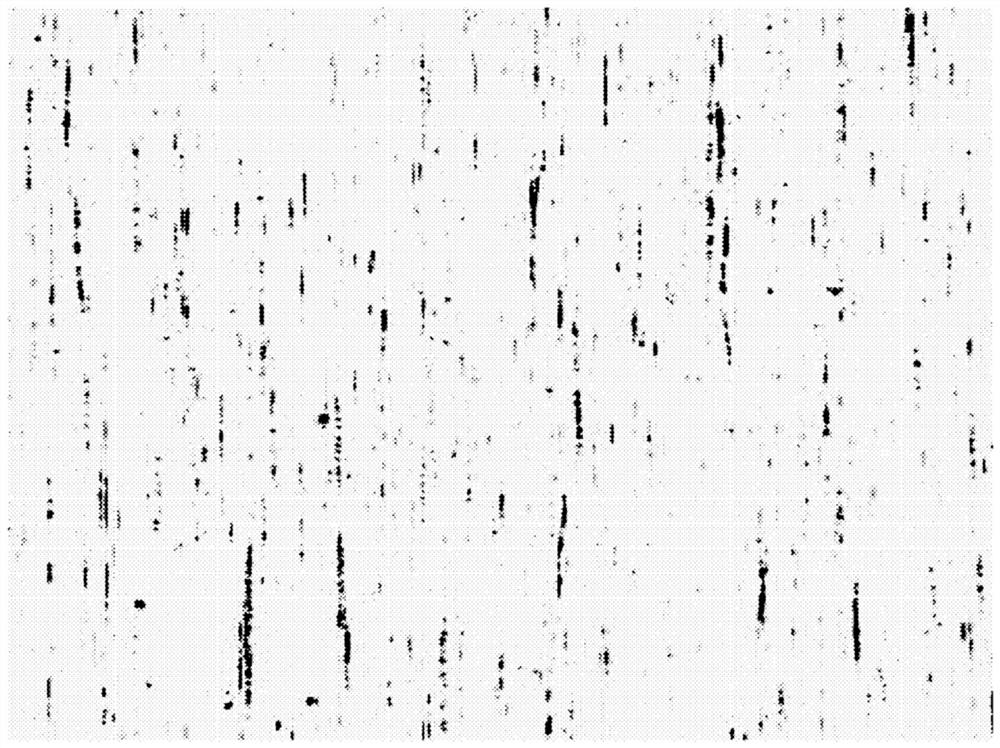

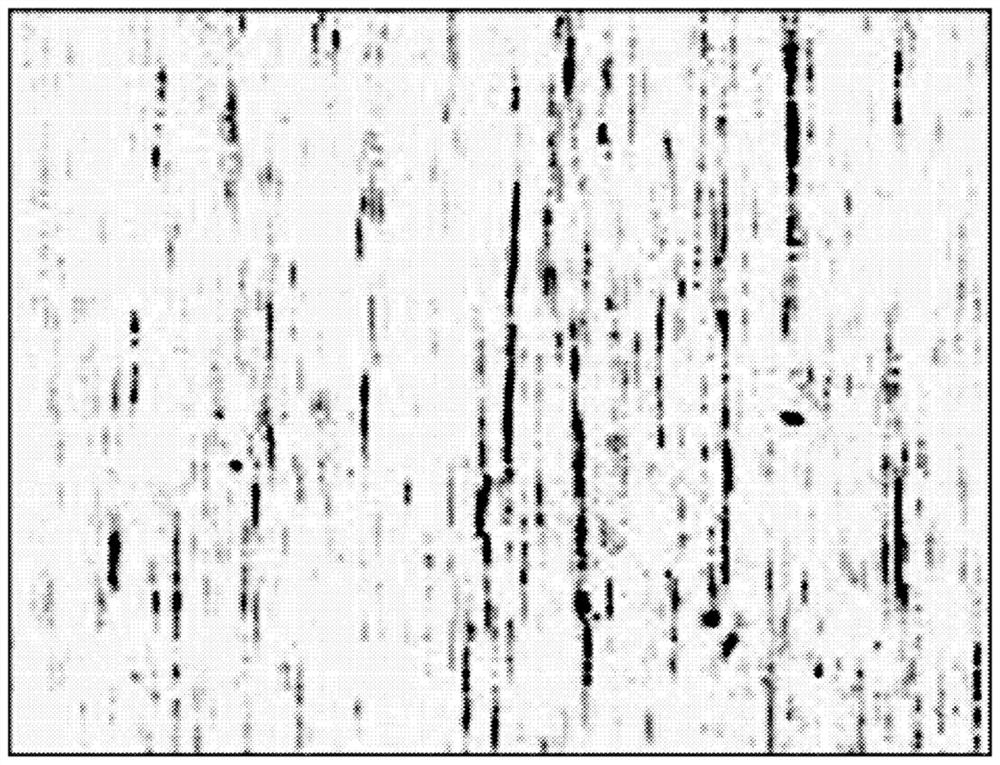

[0087] The samples were processed and subjected to a 15% tensile test in directions of 0°, 45° and 90° with respect to the rolling direction to measure the r value (Lankford value). From the r values measured in all directions (r 0 、r 45 and r 90 ) to calculate the r-bar value (r-bar=(r 0 + r 90 +2*r 45 ) / 4). In addition, the wri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com