Multi-joint robot and system

A technology of robots and joint axes, which is applied in the direction of manipulators, mechanical equipment, program-controlled manipulators, etc., and can solve problems such as insufficient range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

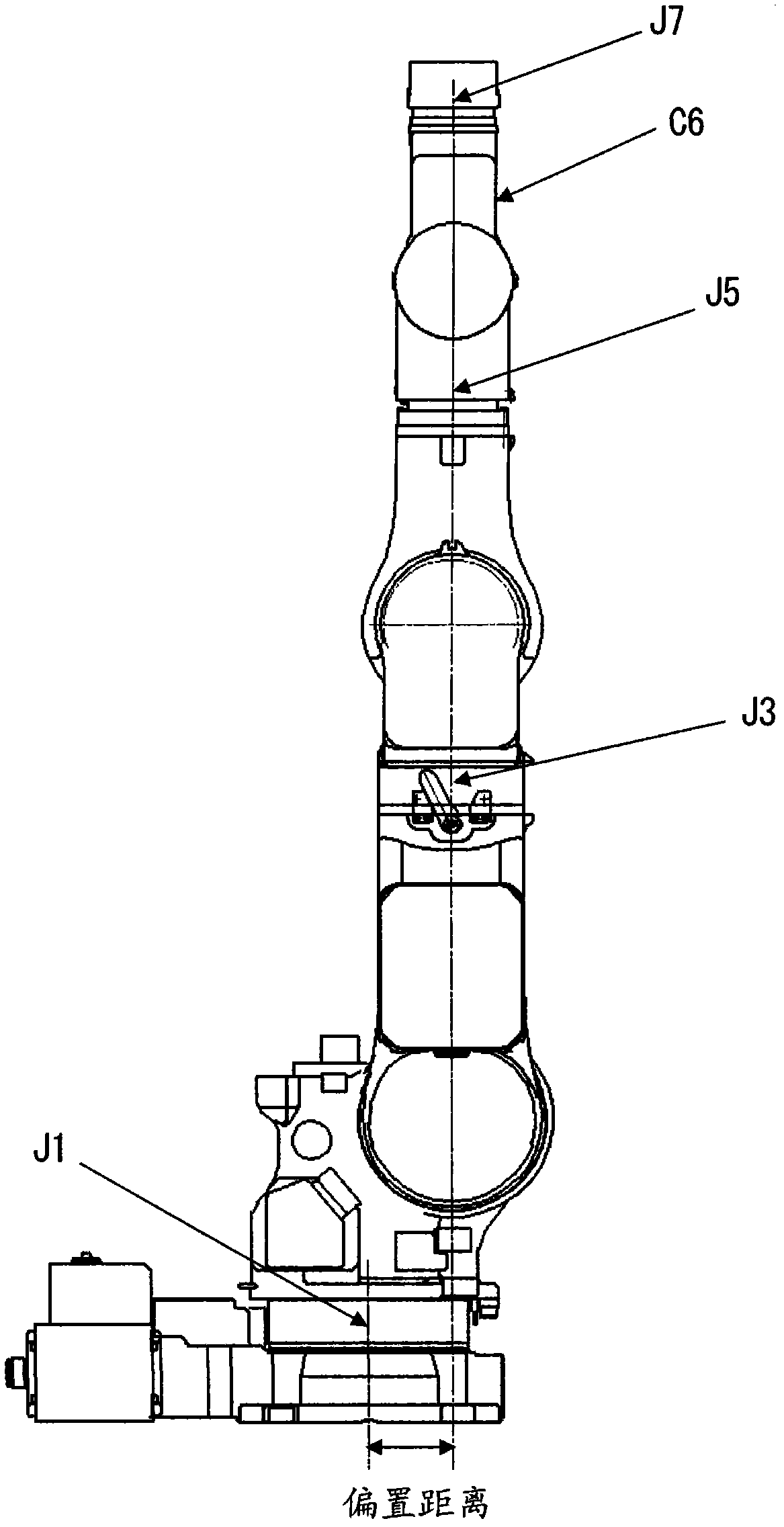

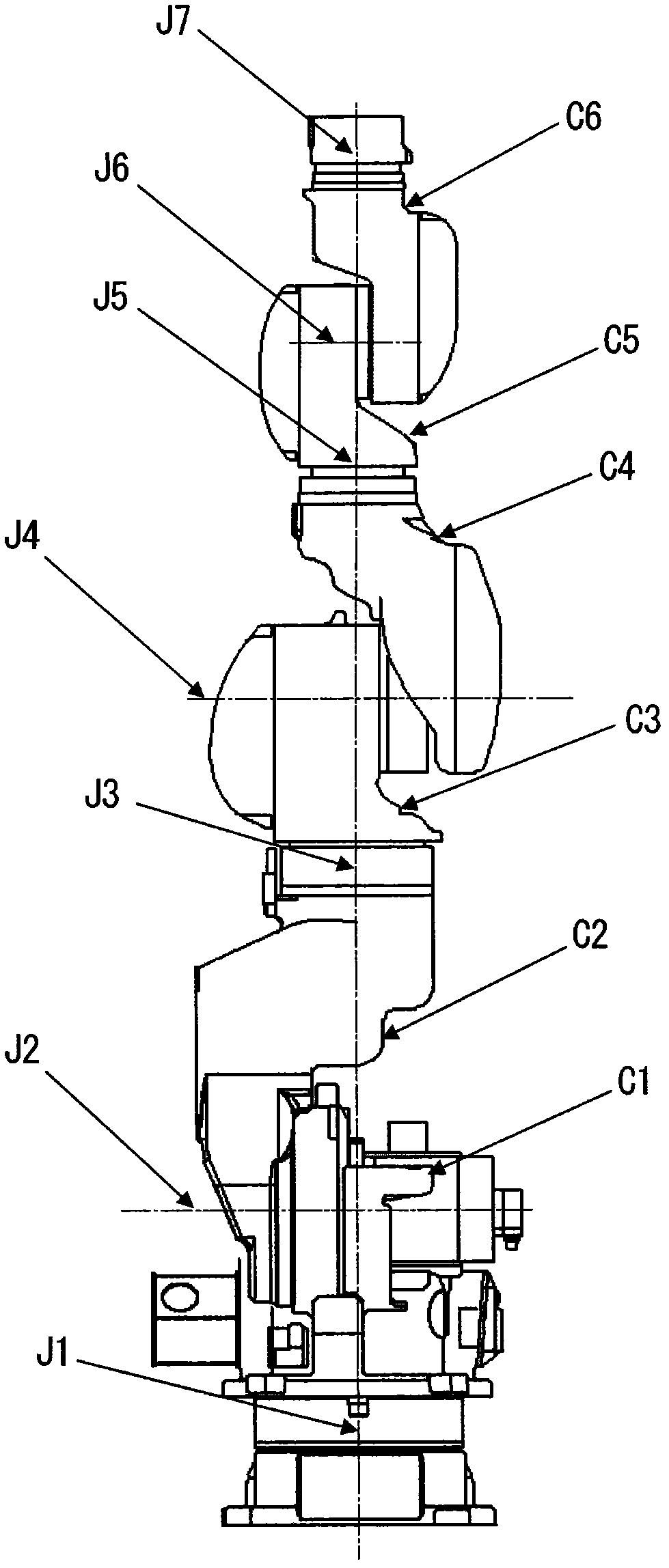

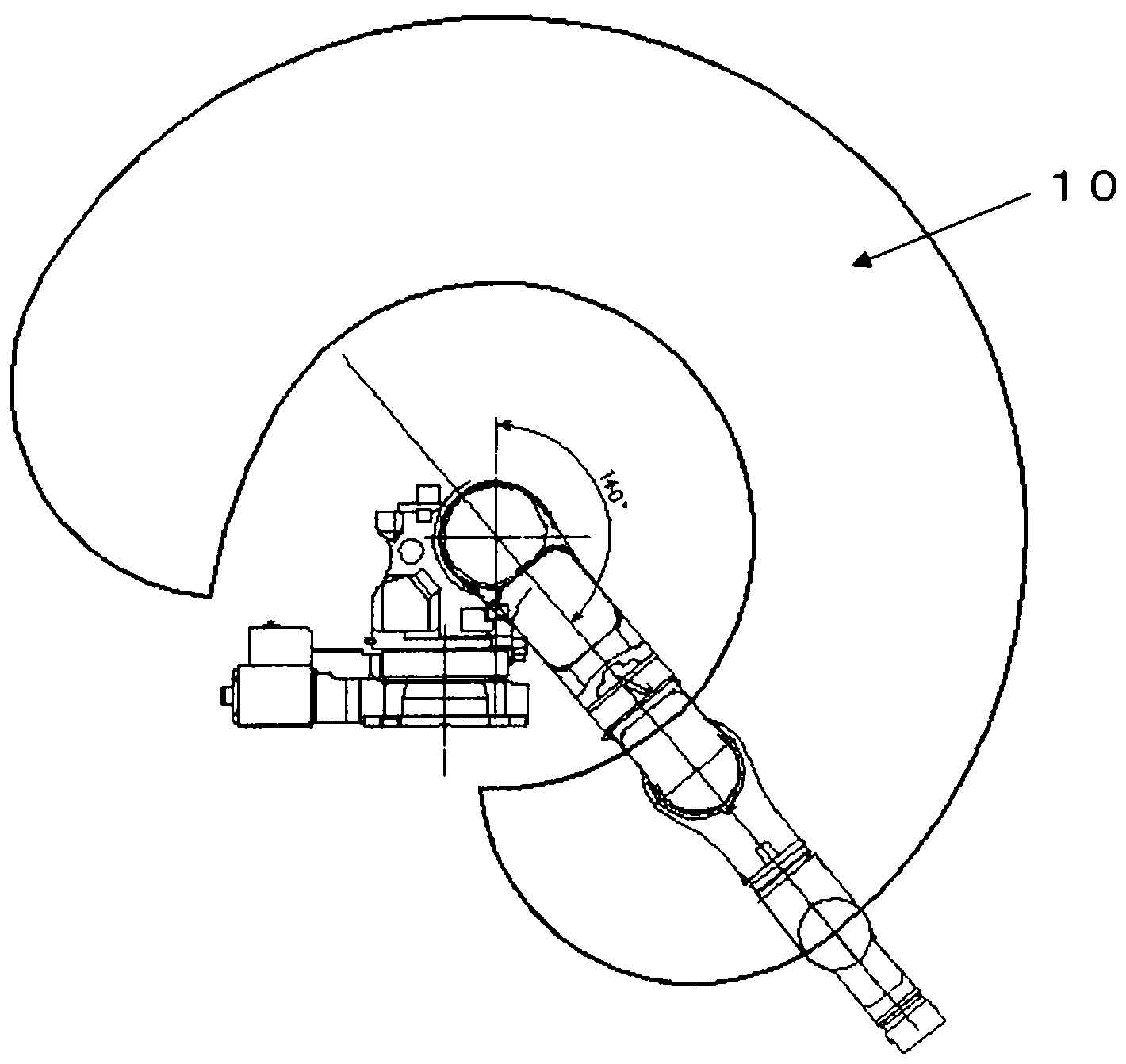

[0024] figure 1 is a side view of a robotic manipulator illustrating an embodiment of the present invention, figure 2 is its front view. The arm body C6 at the free end has a joint axis J7, and for example, a hand device having a force sensor, a spot welding device, and the like are attached to the joint axis J7.

[0025] The first arm body C1 rotates about a first joint axis J1 arranged vertically in the horizontal plane, and the second arm body C2 rotates about a second joint axis J2 arranged perpendicular to the first joint axis J1. The three-arm body C3 rotates around the third joint axis J3 arranged orthogonally to the second joint axis J2, and the fourth arm body C4 rotates around the fourth joint axis J4 arranged orthogonally to the third joint axis J3. The fifth arm body C5 rotates around the joint axis J5 arranged parallel to the fourth joint axis J4, and the sixth arm body C6 rotates around the joint axis J6 arranged orthogonally to the fifth joint axis J5. rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com