Apparatus for needling a fibrous web

A fiber web and equipment technology, which is applied in the field of fiber web needle punching equipment, can solve the problems of complex mechanical devices, insufficient needle beam guidance, and insufficient stability of the needle beam, etc., to achieve increased adjustment range and high passing speed , the effect of stabilizing guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

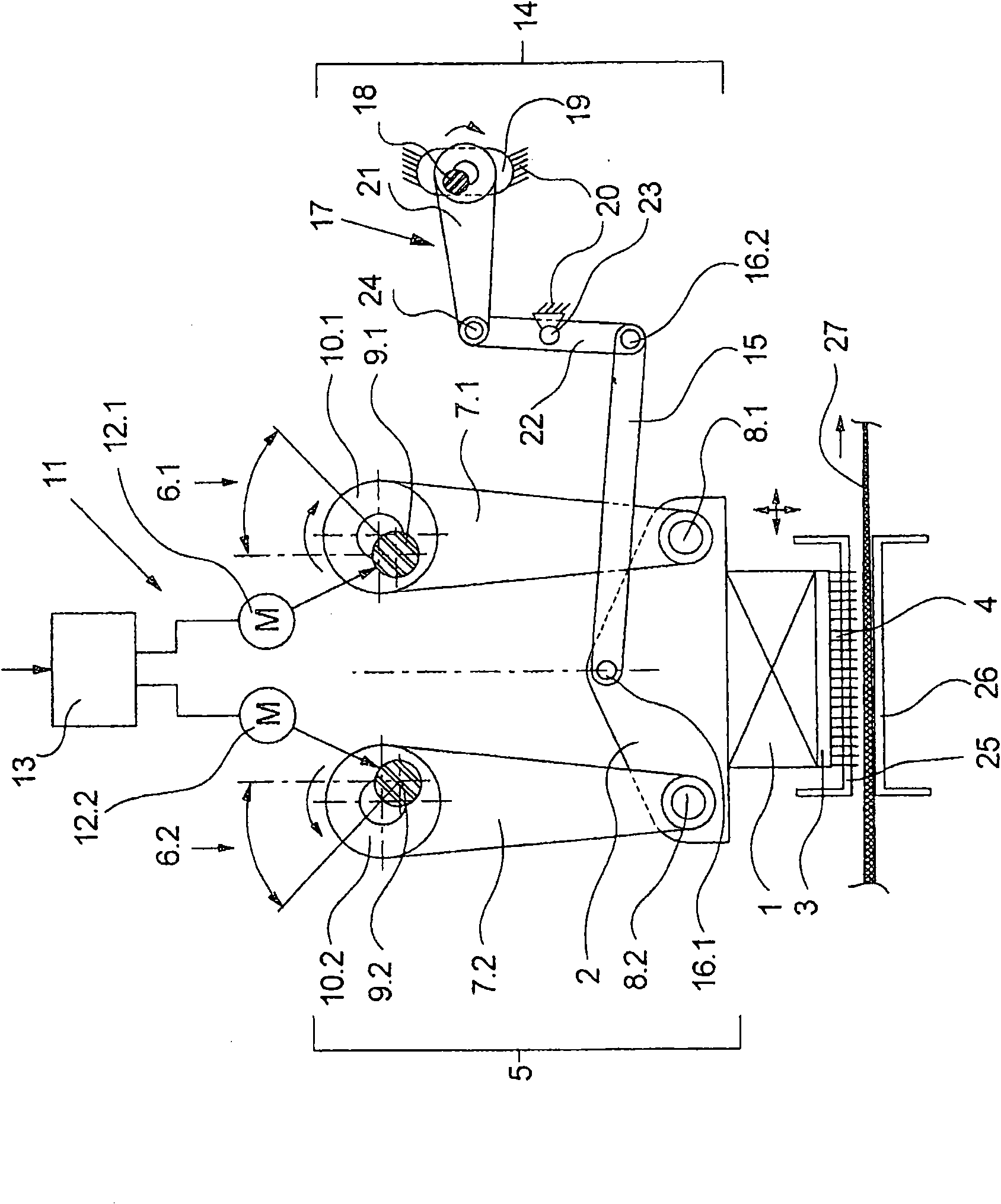

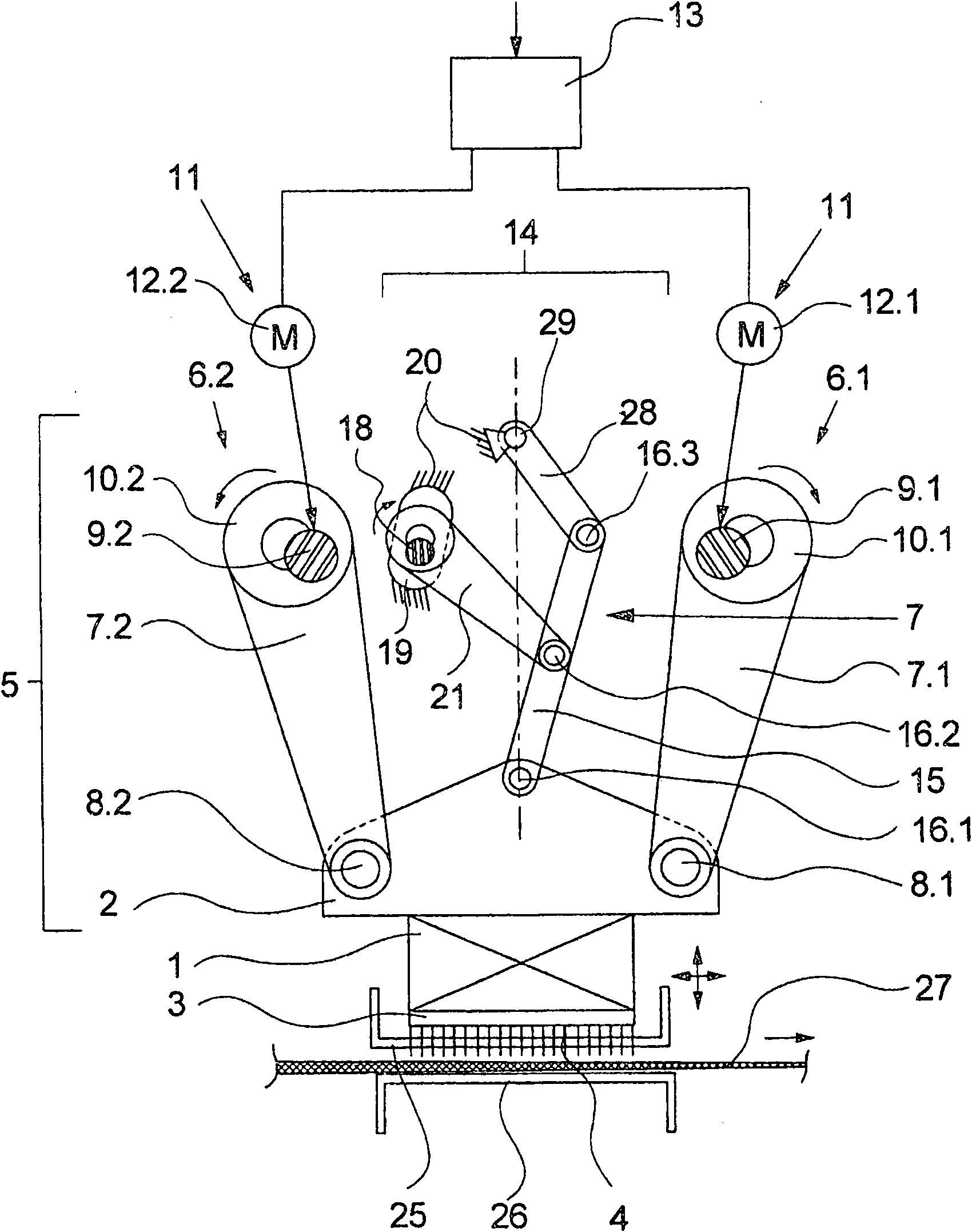

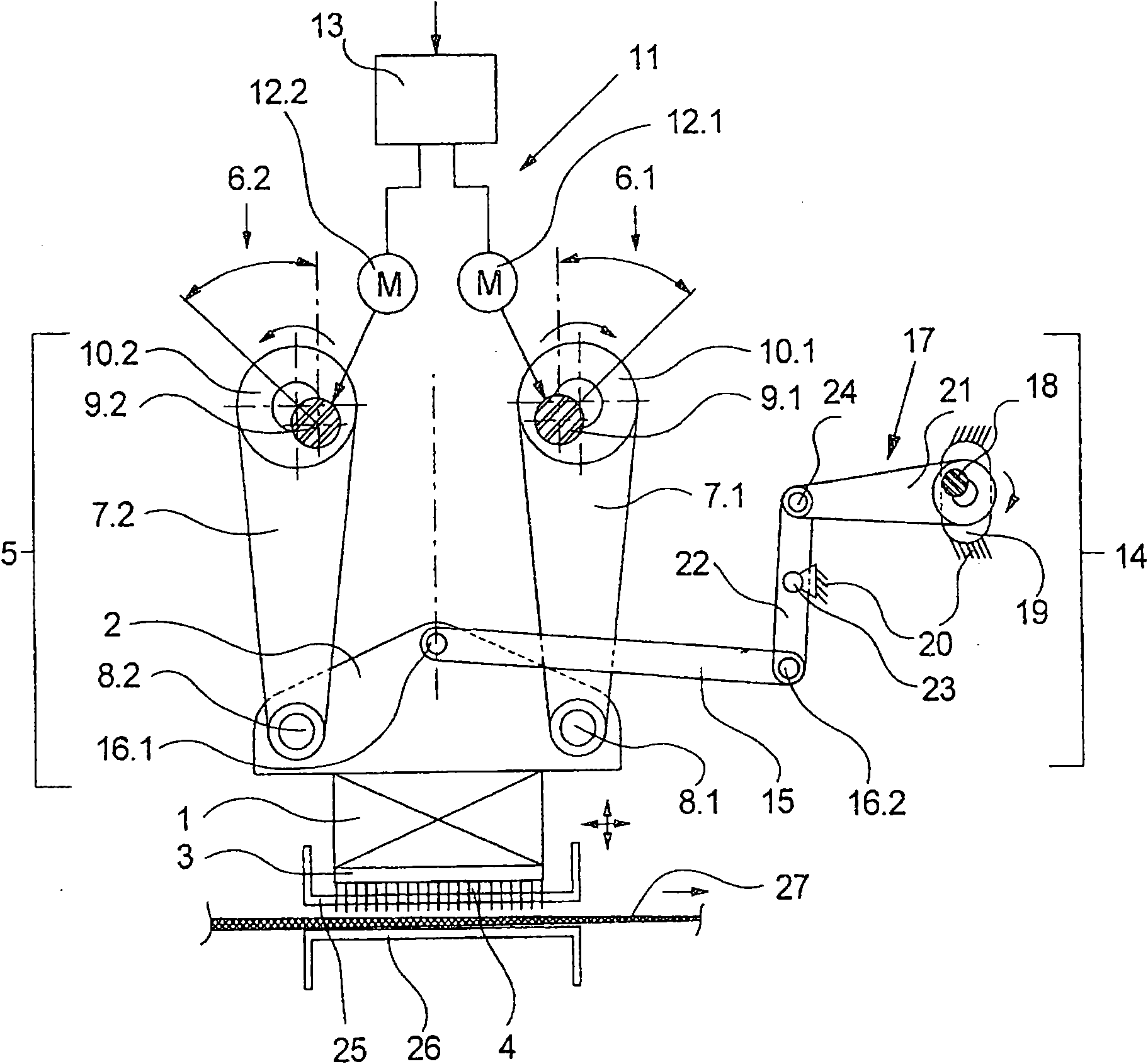

[0022] exist figure 1 A first embodiment of the apparatus according to the invention for needling a fiber web is schematically shown in . According to the device of the present invention figure 1 The exemplary embodiment shows a beam support 2 which holds a needle beam 1 on its underside. The needle bar 1 has a needle board 3 comprising a large number of needles 4 on its underside. A base plate 26 and a needle lifter 25 are assigned to the needle plate 3 including the needles 4 , a fiber web 27 being guided between the base plate 26 and the needle lifter 25 at a substantially constant feed speed. The direction of movement of the fiber web 27 is here indicated by an arrow.

[0023] A crank linkage 5 acts on the beam support 2 . The crank linkage 5 is formed by two crank drives 6.1 and 6.2 arranged parallel to one another. The crank gears 6.1 and 6.2 have two parallel crankshafts 9.1 and 9.2 which are arranged above the beam support 2. The crankshafts 9.1 and 9.2 each have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com