Underwater aeration disk for aquaculture

An aquaculture and supervisory technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of increased pressure of connecting pipelines, inability to add oxygen, difficult to increase oxygen, etc. The effect of easy oxygenation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

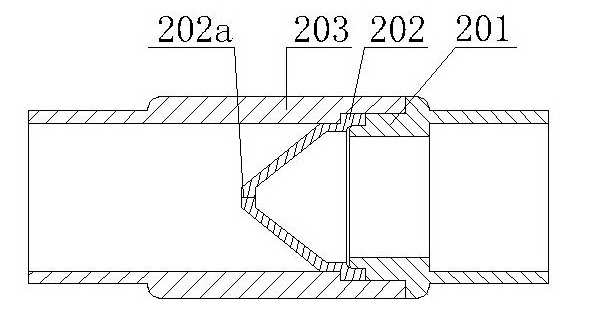

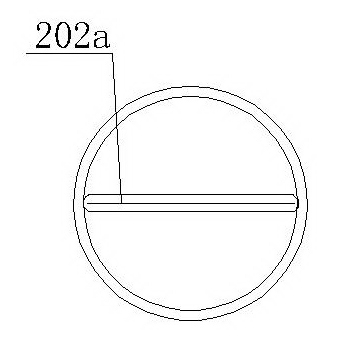

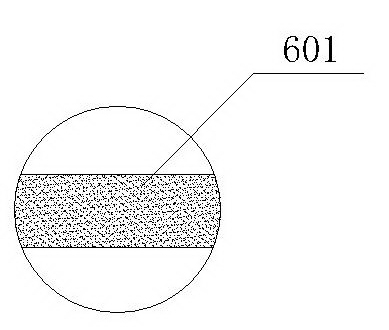

[0016] As shown in the figure, the underwater aeration panel for aquaculture includes a main pipe 3 and a plurality of branch pipes 4 connected to the main pipe 3 , and a main valve 1 and a check valve 2 are arranged on the main pipe 2 . The non-return valve 2 is composed of an inner tube 201 and an outer tube 203 that are set and bonded together, and a rubber sleeve 202 that is fixed between the inner tube 201 and the outer tube 203 at one end. The other end of the rubber sleeve 202 is provided with a gap 202a, and the parts of the rubber sleeve 202 located on both sides of the gap 202a are inclined. An air chamber 6 is connected to the end of the branch pipe 4 through a connecting pipe 5 , and micropores 601 are provided on the air chamber 6 . The air chamber 6 is made of a hollow air stone.

[0017] When in use, connect the connecting air pipe to the intake end of the main pipe 4, then put the aeration disk into the bottom of the water, and after the aeration pump is turne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com