Automatic clamping machine of denitration catalyst module

A denitrification catalyst and clamping technology, applied in the field of denitrification catalyst module automatic clamping machine, can solve the problems of high technical level requirements for workers, large module damage, high labor intensity, etc., and achieve fast action response, high operating efficiency and frictional resistance small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

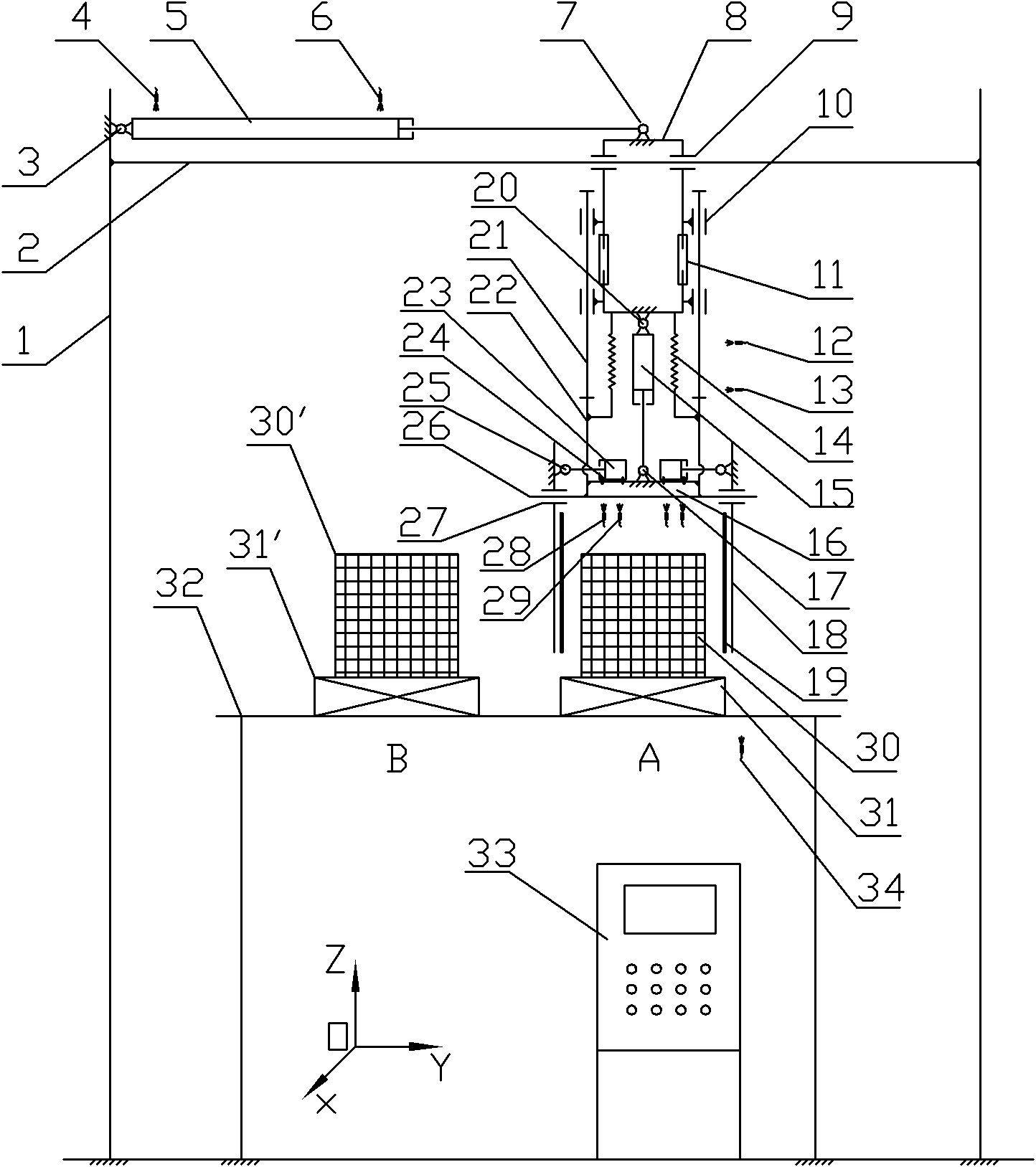

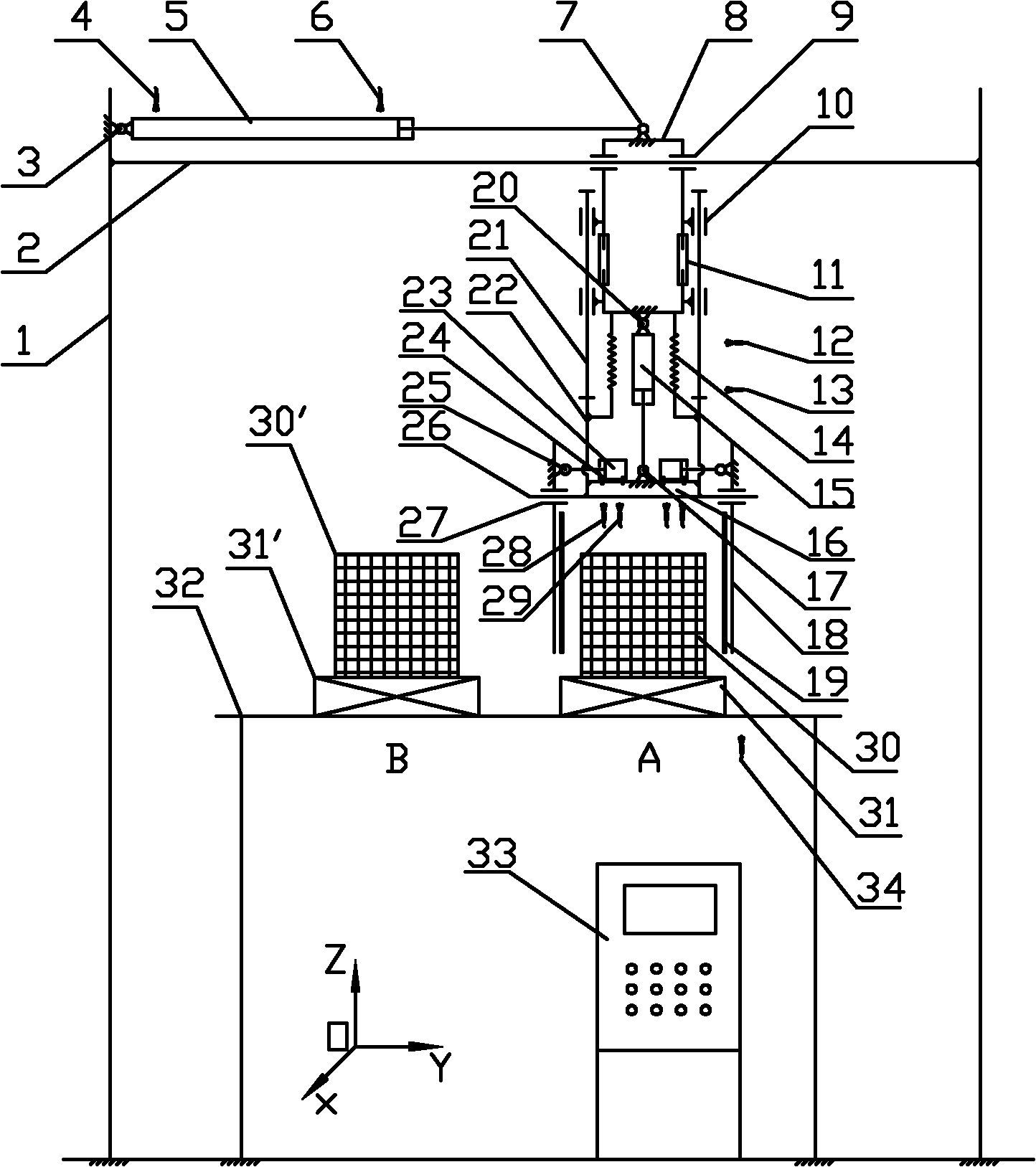

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] figure 1 Among them, including clamping machine frame column 1, clamping machine beam horizontal sliding guide rod 2, horizontal moving cylinder bottom twist support 3, horizontal cylinder retraction position electromagnetic induction switch 4, horizontal displacement cylinder 5, horizontal cylinder push-out position electromagnetic induction Switch 6, horizontally moving cylinder head twisting support 7, moving portal frame 8, linear bearing 9, linear bearing 10, height adjustment bolt 11, electromagnetic induction switch 12 for lifting cylinder retraction position, electromagnetic induction switch 13 for lifting cylinder push-out position, balance Spring 14, lifting cylinder 15, clamping support 16, lifting cylinder head twisting support 17, splint 18, sponge 19, lifting cylinder bottom twisting support 20, lifting sliding guide rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com