Long-life guide wheel assembly for high-speed reciprocated WEDM machine tool

A technology of reciprocating wire walking and electric discharge wire, which is applied in the direction of electrode manufacturing, electric processing equipment, metal processing equipment, etc., can solve the problems such as the short life of the V-shaped groove of the guide wheel, the damage of the bearing, and the impact on the service life, so as to achieve the sealing effect Good, prolong the service life, and ensure the effect of insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

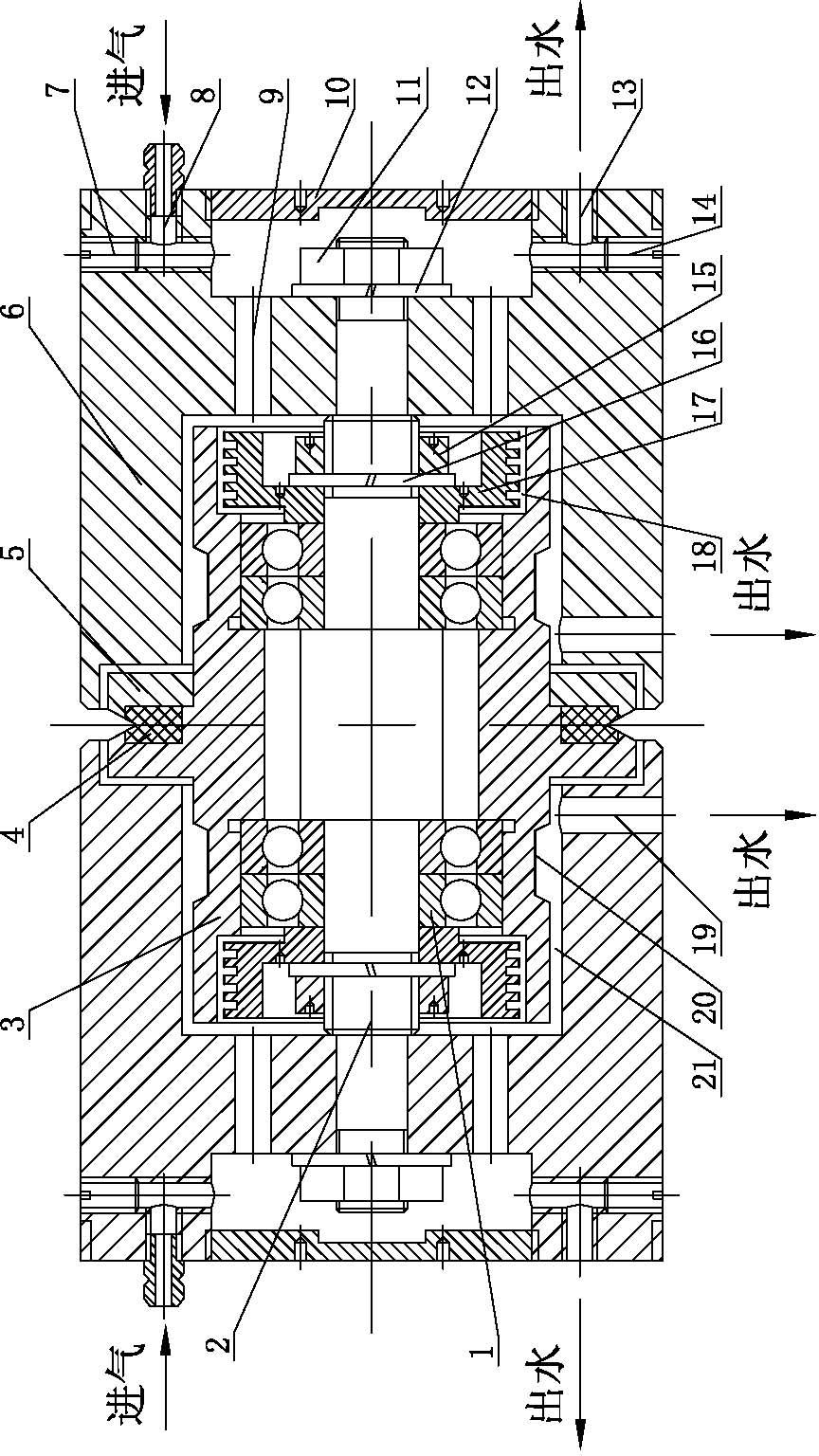

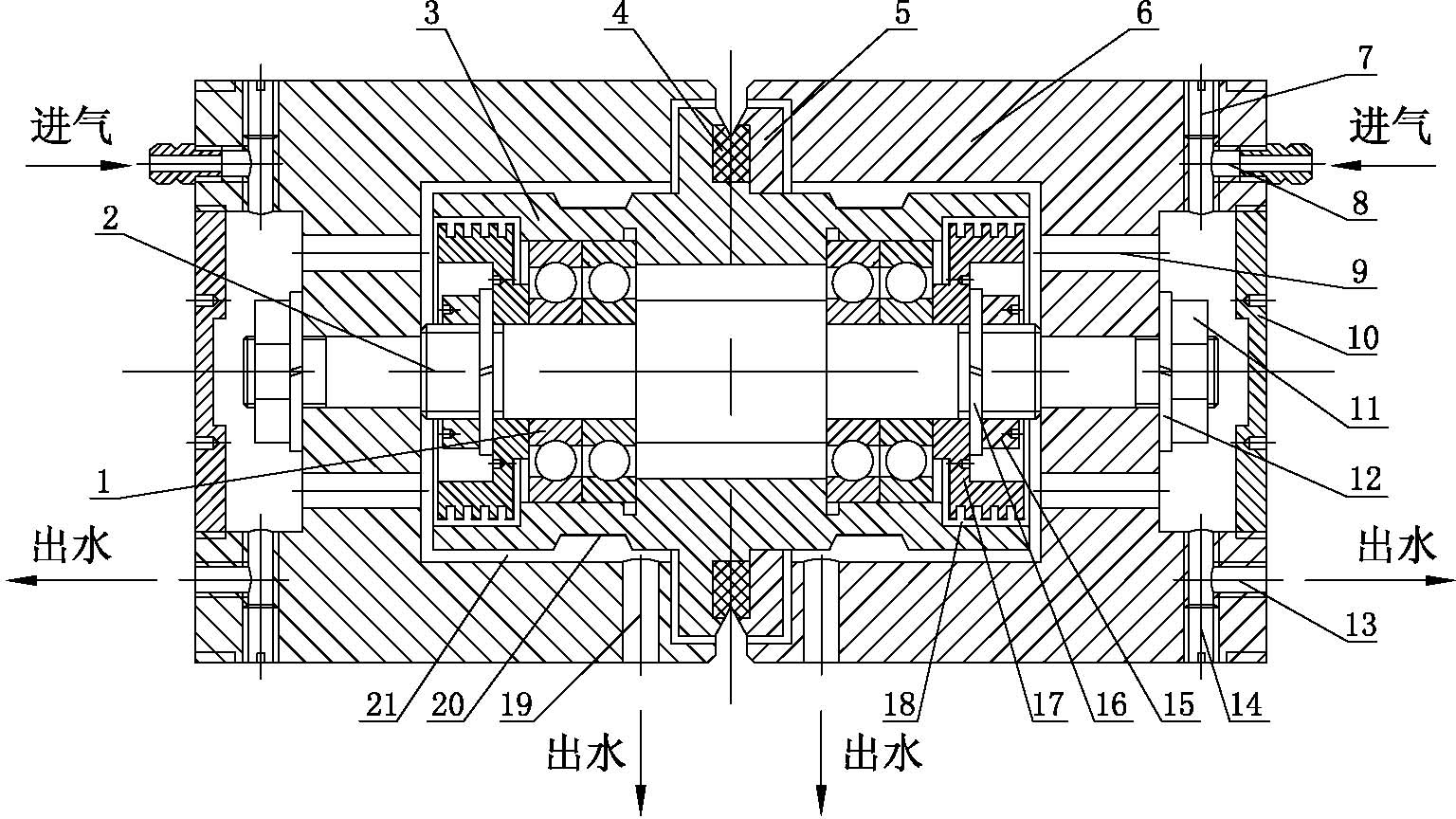

[0019] like figure 2 shown.

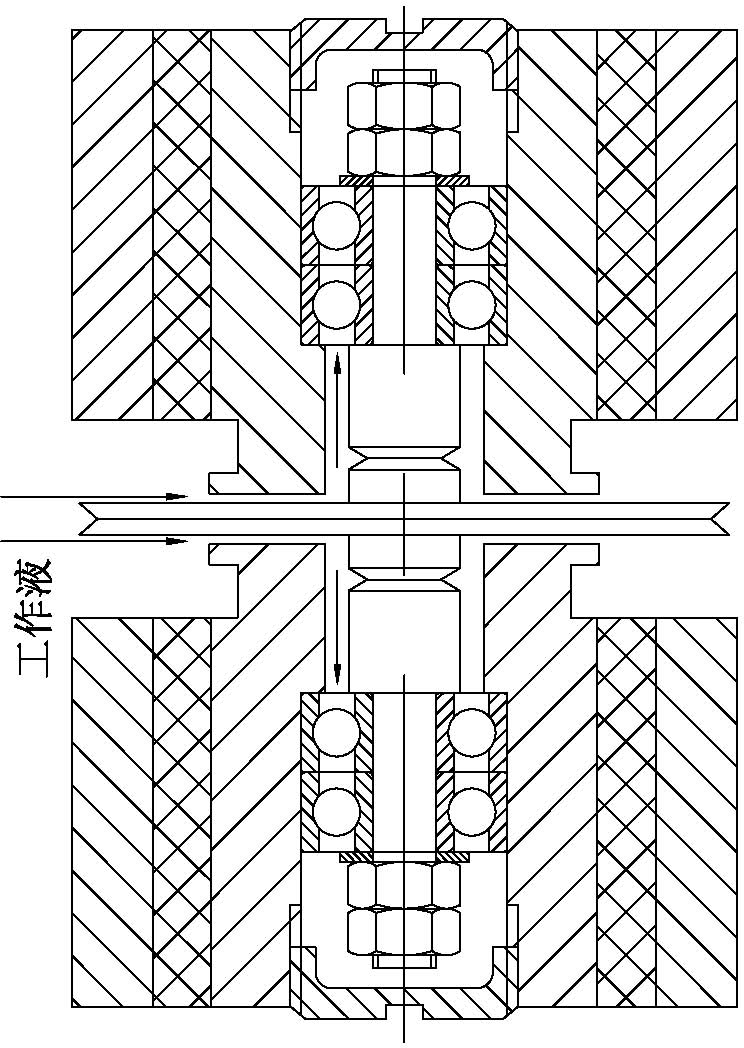

[0020] A long-life guide wheel assembly for a high-speed reciprocating wire electric discharge machine tool, which includes two guide wheel sleeves 6 and a stepped shaft 2, the two guide wheel sleeves 6 are symmetrical to each other in structure, and the two ends of the stepped shaft 2 are respectively Fixedly installed in the corresponding guide wheel sleeve 6 by tightening the nut 11 and the elastic washer 12, the bearing 1 is symmetrically installed on the stepped shaft 2 (the number can be one or more), and the guide wheel seat 3 is installed on the bearing 1 On the center of the guide wheel seat 3, the artificial gemstone ring 4 with a V-shaped ring groove is inserted and glued tightly. It is mainly to prevent the edge of the gemstone from chipping; the V-shaped groove of the gemstone can play a good role in wear re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com