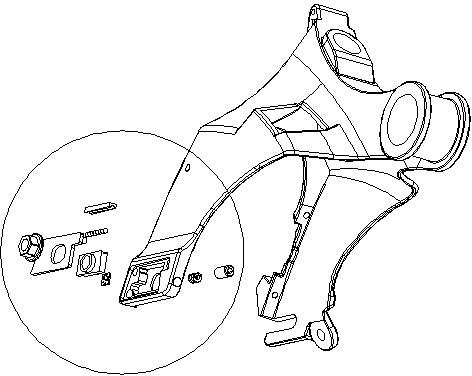

Structure of electric power sensor on bicycle rear fork

An electric power assist and bicycle technology, which is applied to bicycle accessories, vehicle components, and rider drives, etc., can solve the problems of inconvenience, reduced sensor coefficient, weak magnetic induction intensity, etc., and achieves convenient installation and maintenance, good magnetic induction effect, and responsive high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

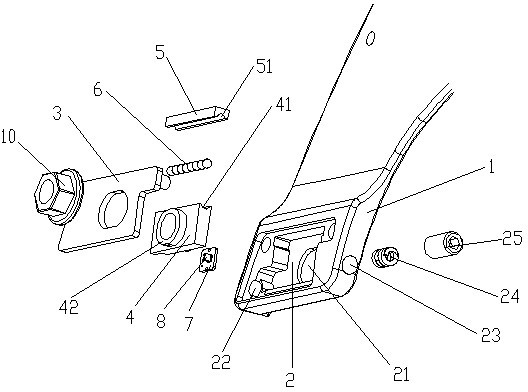

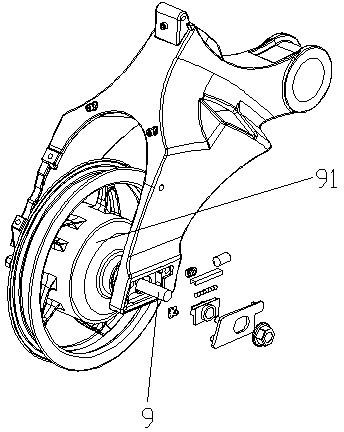

[0018] Attached below figure 1 And attached Figure 5 Embodiments of the invention are illustrated:

[0019] see figure 2 , image 3 with Figure 4 , a structure of an electric power-assisted sensor on the rear fork of a foldable electric bicycle is provided. A groove 2 is arranged at the bottom of one side of the rear fork 1 of the bicycle, and a Hall element is fixedly arranged in the groove 2. The circuit board 7, the groove 2 also contains a sensor assembly on the rear axle 9 that passes through the slot 21 at the bottom of the groove 2 and is movable. The sensor assembly includes a positioning block 4 arranged on the rear axle 9, The upper part of the positioning block 4 located in the groove 2 is provided with a lower guide rail 41, a fixed bar 5 is arranged above the positioning block 4, and an upper guide rail 51 is provided at the bottom of the fixed bar 5, and the upper guide rail 51 and the lower guide rail 41 are provided with Ball or ball strip 6; see Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com